Thatgrimguy

New member

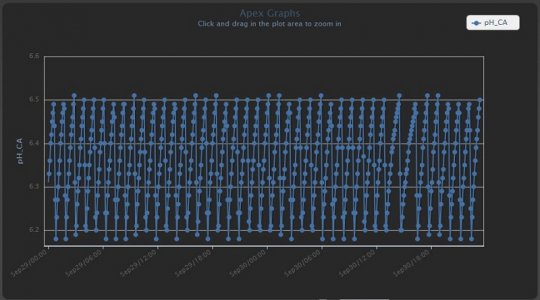

I got a great deal on a calcium reactor and am going to set it up to be run by my Apex.

I was told that when you use a controller the bubble rate doesn't matter much because the controller will control the solenoid to control the ph rather than the bubble counter. Does this sound right? The unit I got is a reef octopus 2 chamber with a holder for the ph probe.

I was told that when you use a controller the bubble rate doesn't matter much because the controller will control the solenoid to control the ph rather than the bubble counter. Does this sound right? The unit I got is a reef octopus 2 chamber with a holder for the ph probe.

Last edited: