Fail

Fail

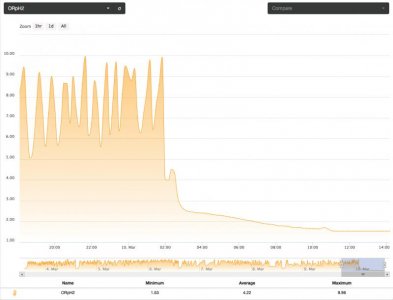

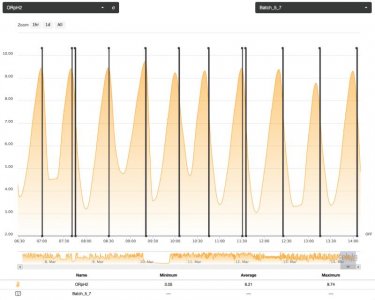

Well... The Bioreactor shut down last night about 2:00 AM. You can see the ORP graph attached.

The process pump circulates a batch of water and a dose of carbon through the reactor by pushing water from the reactor side to the inlet side; back into the reactor through the distribution pipe. My assumption was that I could stir the bioballs and keep that path clear but I failed to consider the distribution pipe. The distribution pipe became so clogged with biomass that the water level on the inlet side increased to the point where it reached the overflow port. This essentially drained the bioreactor below the ORP probe, so it stopped working.

I was able to run a brush through the clean out port, that I added last minute and the water levels quickly returned to start-up levels. However, this is far from "automatic" and for this to be required so soon, just a few weeks after start-up is a major set-back.

Fail

Well... The Bioreactor shut down last night about 2:00 AM. You can see the ORP graph attached.

The process pump circulates a batch of water and a dose of carbon through the reactor by pushing water from the reactor side to the inlet side; back into the reactor through the distribution pipe. My assumption was that I could stir the bioballs and keep that path clear but I failed to consider the distribution pipe. The distribution pipe became so clogged with biomass that the water level on the inlet side increased to the point where it reached the overflow port. This essentially drained the bioreactor below the ORP probe, so it stopped working.

I was able to run a brush through the clean out port, that I added last minute and the water levels quickly returned to start-up levels. However, this is far from "automatic" and for this to be required so soon, just a few weeks after start-up is a major set-back.