Notathumpa

New member

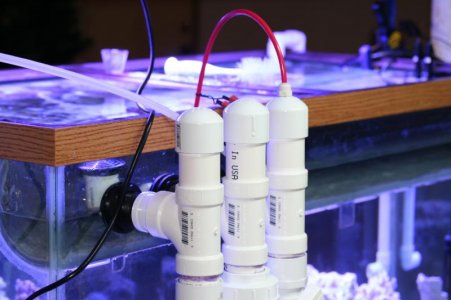

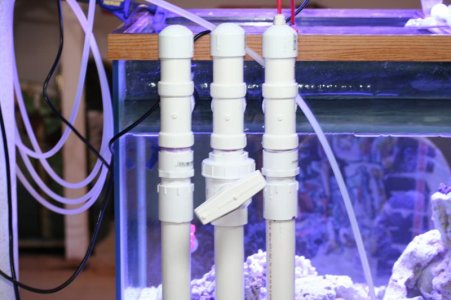

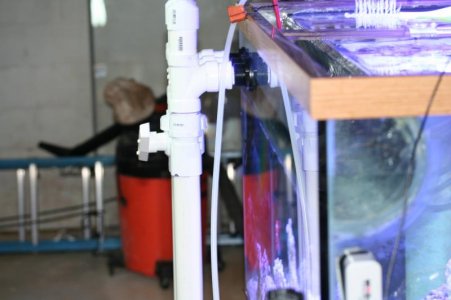

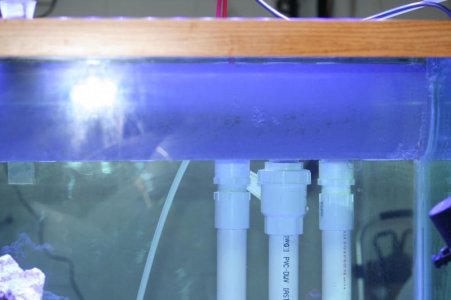

I DIY'd a coast to coast o'flow from a piece of 6" schedule 40 PVC pipe and added the bean animal overflow system. It works like a charm! Though the sched. 40 was a bit heavy, it does lose itself in the tank because of it's grey color. I cut the pipe (48") lengthwise to adapt to the smallest radius profile (could've gone a little smaller) and used 1" street elbows in tank to 1 1/2" outside of tank, just like Bean's page shows. Very impressed at it's efficiency and quiet operation. If anyone is interested, I'll post some pics of finished product. It was so much cheaper and easier than acrylic o'flow fabrication.