slief

RC Sponsor

Hi Scott,

Can you advise on the following,

139 gallon LPS system (Reefer XL525)

Skimmer Mini Bubble King 200 VS13 with RD3 Mini Speedy

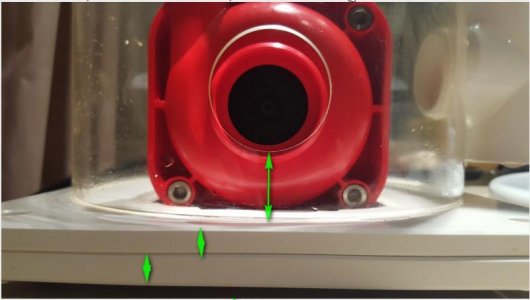

Actual sump water level is 10.8" (27.5cm) and skimmer on a stand-plate to bring skimmer water level to 8" (22cm).

In order to raise the water level at the waterlevel limite in the skimmer body, I need to close the wedge pipe at 80-85%. it is normal to close that much in order to bring the waterlevel at the limite line ?

I've tried to run at full 50w but also at 30w but no real changes.

Skimmer is running since two months now and the tank population 12 fishes 6 shrimps. Before the 200 RD3 , I had the Mini180 on the 450L Reefer with a sump waterlevel of 24cm and on a stand-plate to bring skimmer water level also to 8" (22cm) but wedge pipe was only closed at half way only.

Any suggestions?

Cheers

You hardly have any load at all for that skimmer. There really isn't much waste in your tank.

My suggestions would be as follows. Lower the stand. Your wedge pipe is closed too much for my liking and you are having to do that to compensate for the skimmer being too far above the water. I would start at around 9" depth for the skimmer and see how that does. Your best pump speed should be between 28 and 32 watts. Like I said in the suggestion above, set the pump speed to get the best/most dense foam possible which in the case of the 200mm sized skimmers is between 28 and 32 watts.. The more dense the foam, the better a job it will do in removing dissolved organics. Keep in mind that the lower pump speed allows for better contact time which means more waste will be removed in a single pass and you will have better foam and better control over fine tuning of the skimmer. The RD3 allows for very fine adjustments for that so make an adjustment and give it time to settle down. Take notes if needed so you know what your adjustments did and find a setting that gives you the best foam.

Once you figure out the best pump speed setting for your load, Use your sump depth to get the level inside the skimmer (where the bubbles turn to foam) right at the base of then neck where the cup threads to the body. You want to do this with the wedge pipe wide open as that will be your driest skim set point. If your sump level can be lowered, I would remove the stand and drop the level to 9" with the wedge pipe wide open and see what that does. If the transition from bubbles to foam is too low, increase the sump depth slightly until you find the sweet spot. If it's too high, drop it some more or raise your skimmer slightly. Give it time for the skimmer to settle down after making adjustments. It can take several hours for the skimmer to settle down. Once you get that set, then you can use the wedge pipe to adjust from a dry skim to a wet skim without having to close it too much. A tiny adjustment of the wedge pipe will make a big difference in the foam level once you get the sump/skimmer depth set right and you will never need to close the wedge pipe all that much. If you don't have the ability to lower the sump level or lower the skimmer stand, then you will be stuck having to use the wedge pipe and close it more than 1/2 way. This isn't a huge issue as long as you don't experience surging in the skimmer body. This is where the water level in the body goes up and down and it's caused by the exit side of the skimmer being restricted too much. This causes water to siphon out of the skimmer instead of flow out nice and smooth. .

Last edited: