JohnPaulGross

New member

What are your humidity plans? That's one thing I thought of but underestimated when I build my ~850ish gallon tank... also what are you planning to light it with? With it being that deep you will need something serious. I'm running LEDs now but I'm thinking about dropping in 4 solar tubes.... Ill definetly be tagging along

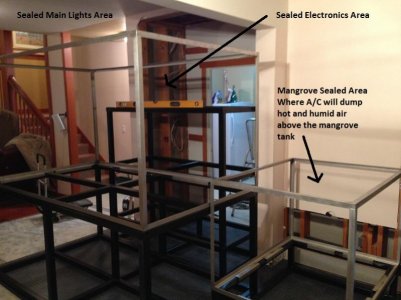

So for the humidity I have an interesting plan. I bought a small A/C unit from Costco and the plan is to isolate and seal the area above the main tank where the lights will be, the area where the PLC and electronics will be (shown in the first picture) in between the studs will be sealed in with Plexiglas and the area around the closet stand. Each of these three areas will be served be multiple ducts that converge into a large duct that will connect to the A/C unit (picture 2). The area above the mangrove tank will also be sealed from the top of the tank to the bottom of the light compartment with Plexiglas and from the back a single duct will open into the mangrove system and all of the hot/humid air will be dumped into the system to keep the mangroves hot and damp. I will also have some gauges and a diversion duct so that I can dump the heat outdoors if everything is really overheating, but the area stays pretty cold.

Here is some of the equipment I have gotten for the tank.

2X Hamilton Cayman Sun Reflector 250 Watt DE HQI 14K System

2X AquaticLife Expert Series 46 Inch 234 Watt Cree LED Light Fixture (3 Watt x 72)

The lighting layout will be included with the other diagrams later.

Main pumps...

2X Dolphin Amp Master Diamond External Marine Pump - 6250 GPH (Type-2)

Skimmer...

1X ASM G-6 Protein Skimmer w/ 2xSedra 15000 Pumps

Controller...

1X Digital Aquatics ReefKeeper Elite (Net) Controller

All these components are for the main tank. I have most of the additional pumps and lighting for the rest of the system.

I also have a link for one more video of my bow-front that I took today since the ones I posted yesterday were a bit outdated.

http://youtu.be/KCp-n1gN2XI