herring_fish

Crazy Designer

Has anyone actually run into this problem?

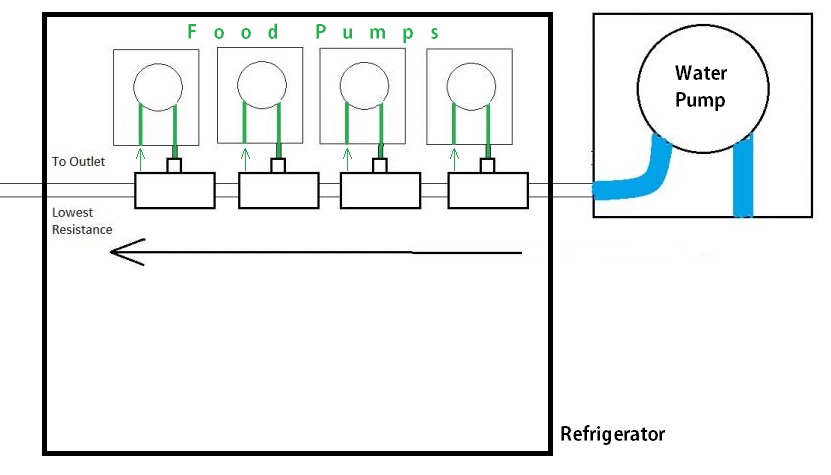

My intent is to simply have a bigger peristaltic pump for the water rinse than for the food. I don't know for sure that this will work. I have just assumed that it would. Please give me your thoughts on this. Perhaps I have over looked something.

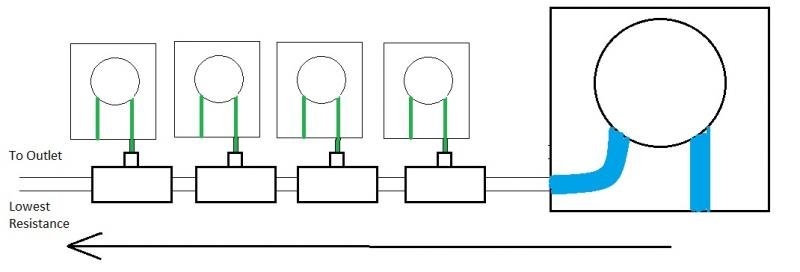

The water pump uses a bigger diameter tube and the motor is bigger so when the smaller motors run, the back pressure should not affect the upstream pumps. I will just have several "T"s in a row after the water pump and then go to the tank from there. The smaller diameter feeder tubes will flow into the bigger, water pump to tank tubing.

The way that I figure it, the very low flow food pumps will not produce much pressure. I will keep the tubes from the food pumps to the "T"s short, inside the refrigerator. The water pump can be outside the fridge. When the water pump turns on, I am hoping that the circuit (if you will) will see the lowest path of resistance after the "T"s . Hopefully, everything will flow toward the tank and not back up any of the feeder tubes and of course not back up to the water pump when the feeders turn on.

My intent is to simply have a bigger peristaltic pump for the water rinse than for the food. I don't know for sure that this will work. I have just assumed that it would. Please give me your thoughts on this. Perhaps I have over looked something.

The water pump uses a bigger diameter tube and the motor is bigger so when the smaller motors run, the back pressure should not affect the upstream pumps. I will just have several "T"s in a row after the water pump and then go to the tank from there. The smaller diameter feeder tubes will flow into the bigger, water pump to tank tubing.

The way that I figure it, the very low flow food pumps will not produce much pressure. I will keep the tubes from the food pumps to the "T"s short, inside the refrigerator. The water pump can be outside the fridge. When the water pump turns on, I am hoping that the circuit (if you will) will see the lowest path of resistance after the "T"s . Hopefully, everything will flow toward the tank and not back up any of the feeder tubes and of course not back up to the water pump when the feeders turn on.