der_wille_zur_macht

Team RC

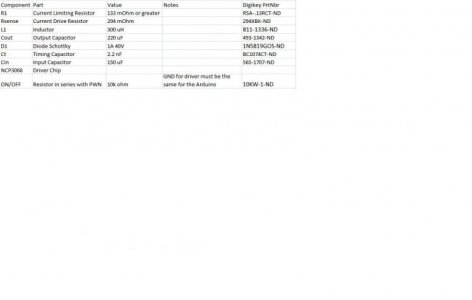

Titeo, if your criteria are in line with what I posted on the first page, the CAT4101 design would be my choice.

The number of DC power supplies you end up using is more a function of the power supplies' capabilities, not specifically the driver you choose (which really only dictates the voltage requirement from the PS).

The number of DC power supplies you end up using is more a function of the power supplies' capabilities, not specifically the driver you choose (which really only dictates the voltage requirement from the PS).