Field Report 2:

So the first mistake I found was that my Rsns (R1) was 0.1 Ohms instead of 0.22Ohms. Good thing I had a few extra, so I added another resistor there (making a small tee pee in the process

). Then the Vadj pin was supposed to be powered by an internal source to 1.24V, but I suspect that my voltage divider messed that up because it was measuring ~0.15V which would explain the low current. So I decided to proceed with analog dimming, which would set the voltage properly on that pin.

So I set the jumpers for analog dining, wire a 5V power source to the ADJ pin and hit the power button. Next thing I know, I'm blinded...

(That string is 3 RB, 3 CW and the rest NWs).

I look at the multimeter to see the current: 860mA! Hooray! I quickly remove the second Rsns resistor to the previous 0.1 Ohms, just to see what happens: 2A

.

For PWM, I'm thinking that until the Vadj pin is completely disconnected, the max current will be set to something very low so PWM will work only on that current.

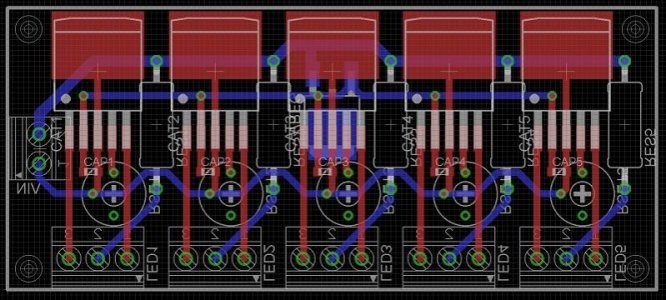

BTW now that I know these work, I have a few extra boards if anyone is interested, send me a PM. I'll test PWM later today and make fixes to the design, than I'll post the eagle files and BOM.

THz