:furious::furious::furious::furious:

I spent 20 minutes on this answer and it vaporized.

So will give the budget repeat.

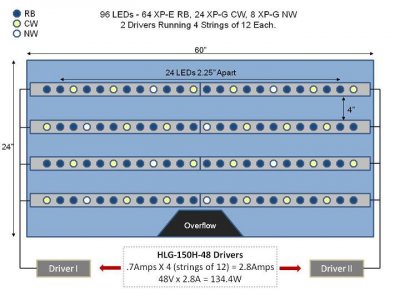

LED drivers are categorized by wattage. You need to come up with a ball park wattage to know where in the families to look.

Watts = 3.3V x 0.8A x the total number of LEDs.

Once this is known you look at the 60, 100, 120, 150, 200, 250, 320 watt models.

The parallel isn't real hard.

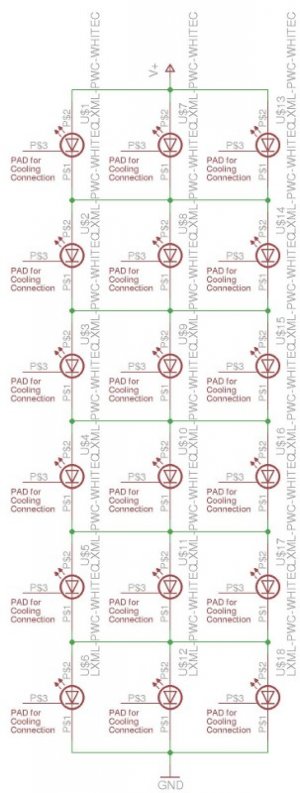

Here's the basic setup:

The resistors are all the same value so you don't have to think about 'different values'.

You'll use them to shift around a few LEDs to get the strings matched current wise.

Hey, let me just say "Thanks". I really appreciate your time and effort in helping me out. I know you guys (and gals) take a lot of your time up answering many many questions, and in some cases over and over again. So just wanted to let you know that it is very appreciated.

Okay, so wattage is clear, parallel setup is clear.

Driver voltage, and calculating which resistors and fuses to use is still fuzzy.

Driver Voltage:

Based on the setup I described earlier, wouldn't each string need ~60 volts in this case (18 LEDs per string x 3.3 = 59.4? Is that correct?).

I think I read that the driver would equally distribute the required voltage to each string, so if all strings are equal, I only need to calculate required voltage for 1 string and ensure the driver can handle that single string voltage (~60 in this case), yet all strings in parallel will receive required voltage?