You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY LEDs - The write-up

- Thread starter JohnL

- Start date

- Status

- Not open for further replies.

TheFishMan65

New member

I don't think you can do that on flat aluminum sheet. It also sounds like a lot of LEDs for that area. 24-36 LEDs are usually good for a 24x24 inch area.

TheFishMan65

New member

Well maybe if you run them low enough, that might also explain why you have so many.

miwoodar

Likey the bikey

i just saw post about the u-channel 1"wide 1/2"tall 1/8"thickness for 24 inches is only $2.13 each at speedymetal.com /snip/

I'm interested in knowing if 1/2" tall would be enough as well.

The Grim Reefer

Ready for some NOBALL!!!

I used 2x1 U channel and it's fine. Not really sure if the smaller stuff would have enough mass unless you use a lot of fans. I use 2 just to be safe.

ReefEnabler

Premium Member

Guys guys, long time no see!

I am moving next month; sold my tank already, sadly won't have a tank for a while!!

Sensing this upcoming "dry spell", I cannot seem to stop craving another project. Been wanting to get into hydroponic gardening for a while now (done some dabbling in peppers already). So I want to turn the garage of my next house into an Aeroponic grow room! (turns out my RO booster pump is the perfect misting pump also!)

First let me say that most of the gardening forums are a SAD sight when it comes to LED info, dear lord. People start a thread asking if LEDs are good... 3 posts say to get a UFO they're great (lol!!), then three more posts of people saying it can't be done and its too expensive. Then I post some real quick info and stats on a DIY LED rig that BLOWS all the commercial fixtures they are discussing out of the water... and they call me a shilll?!?! lolz!

So annnnnnnyways. I think we all here know that LEDs lighting up a small hydro growspace is really no problem at all.

The best way that I can find to do this would be to use the Meanwell 185-48B (or maybe the bigger 240, but probably not necessary).

My idea would be to run the driver at 3 amps and run 8 parellel strings of 12 LEDs (most likely XPGs, but whatever is cheap on DE when I decide to go forward).

So each LED would be running at 0.375ma, close to optimal. I want to run them low power for Eff and also because I don't want any cooling on the actual aluminum channel. I'd rather avoid potential issues where parts of the frame are cold, parts are warm, and as a result the Vf's drift much more than if you had just let the whole thing reach a nice and even temperature. I'm just guessing this would help the parallel strings based off things I've gleaned reading here. But please tell me if I'm wrong

So I am thinking of putting the 1ohm resistors for monitoring, as well as probably 0.7ma or 1a fuses. Haven't looked into these yet, but the idea would be to allow one or several strings to fail before fuses go, hopefully giving me a chance to see the problem (Thanks Kcress for this idea I read from you years ago).

How does my plan sound? Anybody have any suggestions? Tell me I'm a shill? lol

I am moving next month; sold my tank already, sadly won't have a tank for a while!!

Sensing this upcoming "dry spell", I cannot seem to stop craving another project. Been wanting to get into hydroponic gardening for a while now (done some dabbling in peppers already). So I want to turn the garage of my next house into an Aeroponic grow room! (turns out my RO booster pump is the perfect misting pump also!)

First let me say that most of the gardening forums are a SAD sight when it comes to LED info, dear lord. People start a thread asking if LEDs are good... 3 posts say to get a UFO they're great (lol!!), then three more posts of people saying it can't be done and its too expensive. Then I post some real quick info and stats on a DIY LED rig that BLOWS all the commercial fixtures they are discussing out of the water... and they call me a shilll?!?! lolz!

So annnnnnnyways. I think we all here know that LEDs lighting up a small hydro growspace is really no problem at all.

The best way that I can find to do this would be to use the Meanwell 185-48B (or maybe the bigger 240, but probably not necessary).

My idea would be to run the driver at 3 amps and run 8 parellel strings of 12 LEDs (most likely XPGs, but whatever is cheap on DE when I decide to go forward).

So each LED would be running at 0.375ma, close to optimal. I want to run them low power for Eff and also because I don't want any cooling on the actual aluminum channel. I'd rather avoid potential issues where parts of the frame are cold, parts are warm, and as a result the Vf's drift much more than if you had just let the whole thing reach a nice and even temperature. I'm just guessing this would help the parallel strings based off things I've gleaned reading here. But please tell me if I'm wrong

So I am thinking of putting the 1ohm resistors for monitoring, as well as probably 0.7ma or 1a fuses. Haven't looked into these yet, but the idea would be to allow one or several strings to fail before fuses go, hopefully giving me a chance to see the problem (Thanks Kcress for this idea I read from you years ago).

How does my plan sound? Anybody have any suggestions? Tell me I'm a shill? lol

TheFishMan65

New member

It will never work LEDs won't grow plants (coral either).

I don't see anything wrong with the plan. Except that you may want 13-14 (more?) LEDs. I don't recall the Vf at .375 amps, but at 3.4 volts per LED than 48 volts might run 14 LEDs. I think you know how to figure this out (if not post back).

I don't see anything wrong with the plan. Except that you may want 13-14 (more?) LEDs. I don't recall the Vf at .375 amps, but at 3.4 volts per LED than 48 volts might run 14 LEDs. I think you know how to figure this out (if not post back).

ReefEnabler

Premium Member

Thanks for the reply,

yea I can maximize the strings no problem. I just threw 12 out there since it was close. Not sure yet if I will end up with XREs or XPGs or maybe something else. so the Vf isn't known yet (but I know they're all around the same 3.somethin).

I'm also wondering to what extent I should try to 'manually balance' the Vfs. I was thinking of getting a Xitanium wired up wired up with some aligators and disconnects... so I can plug in my LEDs one at a time and make my own "Vf Bins", down to 0.1v or so.

Then I guess I would try to make the Total Vfs of each string be as close as possible.

I've never done that before on such a large scale.

Is it really important to use the same current as my planned current for the intial tests? Ie... do I need to test Vf at .375, or will the results be just as good if I test the LEDs at 0.7a instead? just asking because it will be easier (but rather trivial I guess to do it right).

I'm planning on the HLG 48B model since it has the same dimming interface as the ELN 60-48D (0-10v, at least I think its the same thing as the ELN).

I'd use one Pot to set the max current at .375, and then another pot to control them from cuttoff to .375 (maybe they'll go as low as 0.1a?). The reason is because I will be using tight optics and mounting the LEDs on the ceiling (anybody recall my Wife's ELOS build where we did this?). I know firsthand that it only takes a single LED with tight optics to potentially burn seedling plant tissue (and corals). So dimming is the obvious solution.

*edit* oh yea and in that other gardening forum, some folks eventually did come to my defense and I think I got my point across. So just gotta keep educating people about the big variations out there.

yea I can maximize the strings no problem. I just threw 12 out there since it was close. Not sure yet if I will end up with XREs or XPGs or maybe something else. so the Vf isn't known yet (but I know they're all around the same 3.somethin).

I'm also wondering to what extent I should try to 'manually balance' the Vfs. I was thinking of getting a Xitanium wired up wired up with some aligators and disconnects... so I can plug in my LEDs one at a time and make my own "Vf Bins", down to 0.1v or so.

Then I guess I would try to make the Total Vfs of each string be as close as possible.

I've never done that before on such a large scale.

Is it really important to use the same current as my planned current for the intial tests? Ie... do I need to test Vf at .375, or will the results be just as good if I test the LEDs at 0.7a instead? just asking because it will be easier (but rather trivial I guess to do it right).

I'm planning on the HLG 48B model since it has the same dimming interface as the ELN 60-48D (0-10v, at least I think its the same thing as the ELN).

I'd use one Pot to set the max current at .375, and then another pot to control them from cuttoff to .375 (maybe they'll go as low as 0.1a?). The reason is because I will be using tight optics and mounting the LEDs on the ceiling (anybody recall my Wife's ELOS build where we did this?). I know firsthand that it only takes a single LED with tight optics to potentially burn seedling plant tissue (and corals). So dimming is the obvious solution.

*edit* oh yea and in that other gardening forum, some folks eventually did come to my defense and I think I got my point across. So just gotta keep educating people about the big variations out there.

Last edited:

kcress

New member

Dear Shilly, Where are you moving to?

Also, if running plants.. I'd definitely go with the "budget build"! It's biggest detraction is lack of dimming. Plants don't need any stink'in dimmen. Get your hands on a nice supply, preferably a PFC job. Remember DWZM got some nice ones off epay.

Then line up your LEDs until they're only about a volt shy of your supply voltage and use the adjustable resistor to dial in the string. That will allow you to run any drive you want on individual strings. They also won't care what the next string is doing. Efficiency should exceed a driver. When you come to your senses you'll be able to up the current easily just by adjusting the resistor slider.

Also, if running plants.. I'd definitely go with the "budget build"! It's biggest detraction is lack of dimming. Plants don't need any stink'in dimmen. Get your hands on a nice supply, preferably a PFC job. Remember DWZM got some nice ones off epay.

Then line up your LEDs until they're only about a volt shy of your supply voltage and use the adjustable resistor to dial in the string. That will allow you to run any drive you want on individual strings. They also won't care what the next string is doing. Efficiency should exceed a driver. When you come to your senses you'll be able to up the current easily just by adjusting the resistor slider.

ReefEnabler

Premium Member

Thanks for the suggestion. I will certainly read more into using resistors instead.

I will have to look into that, since I'm not sure what kind of adjustable resistor you mean (a pot, rheo, or did you literally mean just swapping out a variety of different sized resistors?)

You still end up needing to drive a few strings in parallel, since the drivers are not super-high-voltage, right? Why exactly do the strings "not care what the next string is doing", like they do when you run parallel strings on a constant current driver?

I am only moving about a mile away, from Cary to Raleigh. Why? Well for one, my HOA and nosy neighbors basically are driving me out of my current house. Lots of absurd drama been going on and I have no desire be a part of it. No more bossy HOAs for me!

For one, a big tree in my backyard started falling apart about 3 days before hurricane Irene. My 3 yr old daughter was playing under the tree, the limb smacked her on the head and momentarily held her underwater in a kiddie pool. This was a VERY traumatic day for us as we were in the hospital etc, but everybody is just fine.

Had an arborist take a look and he said the tree might come down in the hurricane, and looked sick. We got a quick "OK" from the HOA over the phone to cut down the rest of said tree before Irene (normally you have to ask in writing and give them 30 days to reply). Well, the next day, THREE HOA board members trespassed into my yard, formed a chain and would not let the tree crew work, even when I said in no uncertain terms "Get off my property you are tresspassing". Had to call the Police. The HOA guys had the balls to insist to the police that they had bylaws granting them the right to tresspass. They even said that maintaining the communities tree cover was more important than my daughters injury.

I about lost it, almost took them to court over it. After things calmed down, decided what a good way to make even more enemies, better to just move. And that's only ONE of the crazy over the top things that happened to us in this neighborhood recently.

I will have to look into that, since I'm not sure what kind of adjustable resistor you mean (a pot, rheo, or did you literally mean just swapping out a variety of different sized resistors?)

You still end up needing to drive a few strings in parallel, since the drivers are not super-high-voltage, right? Why exactly do the strings "not care what the next string is doing", like they do when you run parallel strings on a constant current driver?

I am only moving about a mile away, from Cary to Raleigh. Why? Well for one, my HOA and nosy neighbors basically are driving me out of my current house. Lots of absurd drama been going on and I have no desire be a part of it. No more bossy HOAs for me!

For one, a big tree in my backyard started falling apart about 3 days before hurricane Irene. My 3 yr old daughter was playing under the tree, the limb smacked her on the head and momentarily held her underwater in a kiddie pool. This was a VERY traumatic day for us as we were in the hospital etc, but everybody is just fine.

Had an arborist take a look and he said the tree might come down in the hurricane, and looked sick. We got a quick "OK" from the HOA over the phone to cut down the rest of said tree before Irene (normally you have to ask in writing and give them 30 days to reply). Well, the next day, THREE HOA board members trespassed into my yard, formed a chain and would not let the tree crew work, even when I said in no uncertain terms "Get off my property you are tresspassing". Had to call the Police. The HOA guys had the balls to insist to the police that they had bylaws granting them the right to tresspass. They even said that maintaining the communities tree cover was more important than my daughters injury.

I about lost it, almost took them to court over it. After things calmed down, decided what a good way to make even more enemies, better to just move. And that's only ONE of the crazy over the top things that happened to us in this neighborhood recently.

ReefEnabler

Premium Member

Ok I found a budget LED thread by Kcress, so I will make sure I read through it before making him answer the questions which are most likely already answered in there

http://www.reefcentral.com/forums/showthread.php?t=1751598

thanks again

http://www.reefcentral.com/forums/showthread.php?t=1751598

thanks again

kcress

New member

OK good you found it. I was just about to go hunting. It's all in the first page. Then the thread goes off the rails as someone starts asking out epay light engines etc.

Yikes that tree episode was nasty. I'd move too. No way in h3ll I'd ever live in a HOA. They absolutely suck. I have a rental in one and it causes more headaches than any other aspect.

Yikes that tree episode was nasty. I'd move too. No way in h3ll I'd ever live in a HOA. They absolutely suck. I have a rental in one and it causes more headaches than any other aspect.

ReefEnabler

Premium Member

Got a quick binning question for anybody.

I know that higher number+letter is usally better, but it's also usually true that cooler-whites tend to be the higher bins also.

Looking at the XGP in the following bins for use in growing plants. Wanting slightly warm color and best output:

5B1 R4

4A0 R3

According to the Cree datasheet, 4A0 is ~4500k and is right on the BBL, nice.

5B1 is slightly warmer at ~4250k and also very close to BBL. It also is a higher bin -R4. Also says R3 is ~122lm/w and R4 is ~130.

Both are the same price of 5 bucks on a star if you buy 100 or more from cutter

Obviously I'd want to go with 5B1 R4, but for some reason I feel like double checking that it actually would be brighter and warmer... since usually I don't see higher bins with lower kelvins like this.

I know that higher number+letter is usally better, but it's also usually true that cooler-whites tend to be the higher bins also.

Looking at the XGP in the following bins for use in growing plants. Wanting slightly warm color and best output:

5B1 R4

4A0 R3

According to the Cree datasheet, 4A0 is ~4500k and is right on the BBL, nice.

5B1 is slightly warmer at ~4250k and also very close to BBL. It also is a higher bin -R4. Also says R3 is ~122lm/w and R4 is ~130.

Both are the same price of 5 bucks on a star if you buy 100 or more from cutter

Obviously I'd want to go with 5B1 R4, but for some reason I feel like double checking that it actually would be brighter and warmer... since usually I don't see higher bins with lower kelvins like this.

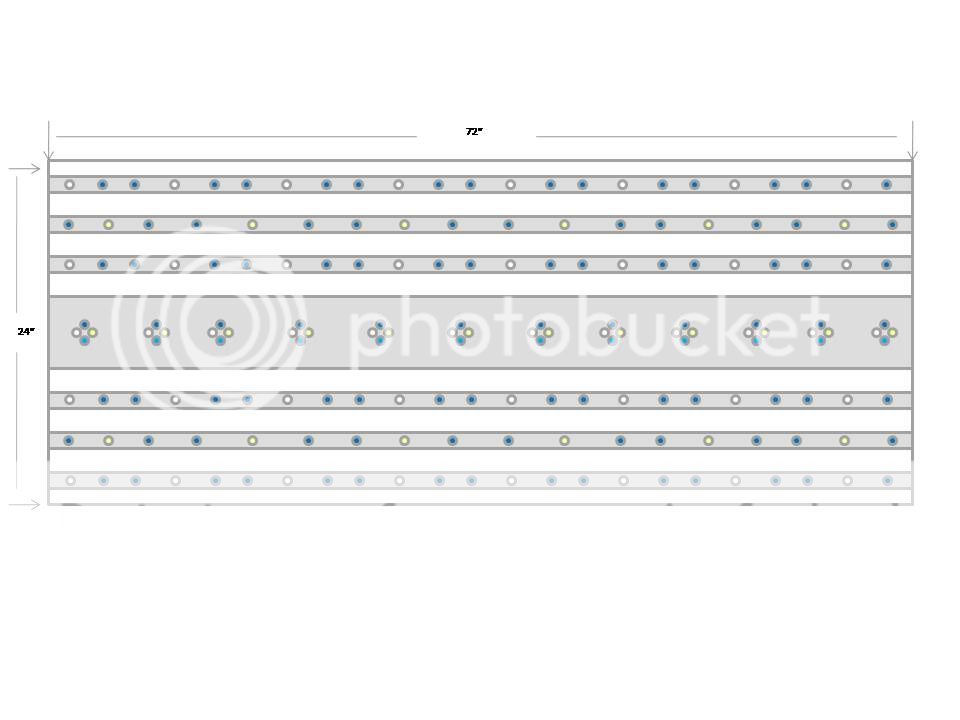

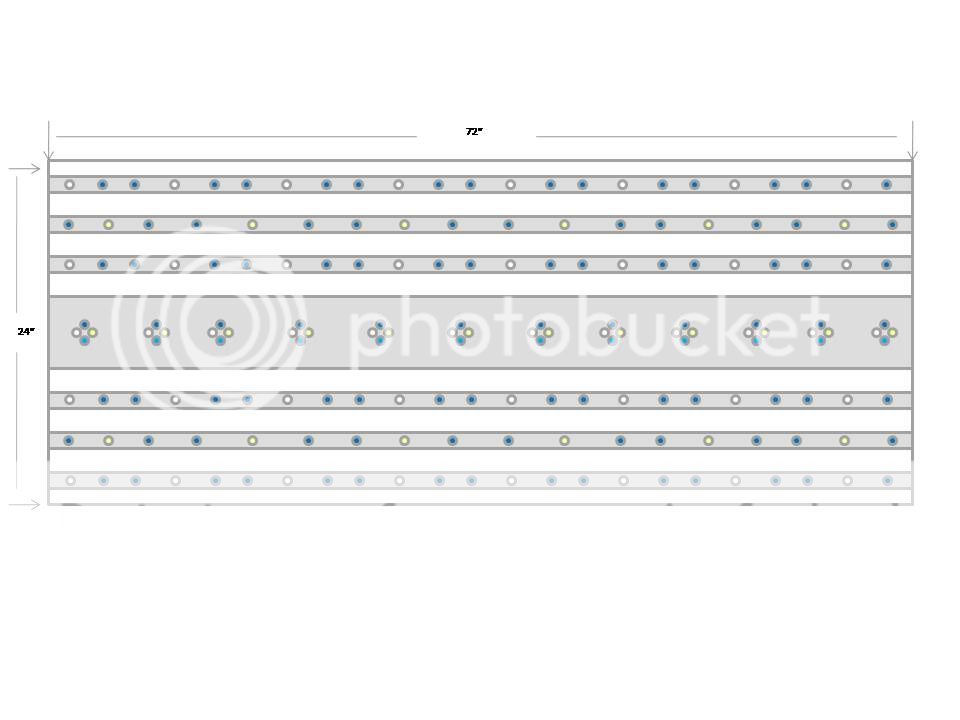

Okay, so I have the following configuration for the DIY fixture I'm making:

I will be lighting a 7' tank with this 6' fixture. This will be done in 6' U-Channel, six 2"x1" and 1 x 4"x2". Here is a picture of the aluminum drilled and assembled:

I will be using the BJB solderless connectors and so the hole pattern you see is for the center cluster of LED's shown on the first picture.

My LED's consist of: 98 XP-E RB, 44 XP-G CW, 24 XP-G NW, 12 XP-E Blue.

I have 3 HLG 150H-48B's and 3 ELN 60-48D's on their way to me and will be separating the colors between the drivers but will have to do some parallel strings.

My question is which resistors and fuses should I buy for the XP-G strings where I plan to run them at about 1100ma? I believe the ones mentioned previously by KCRESS are for when you run the string under 1000ma. I could be wrong but would love a link to the right ones at digikey.

Thanks

I will be lighting a 7' tank with this 6' fixture. This will be done in 6' U-Channel, six 2"x1" and 1 x 4"x2". Here is a picture of the aluminum drilled and assembled:

I will be using the BJB solderless connectors and so the hole pattern you see is for the center cluster of LED's shown on the first picture.

My LED's consist of: 98 XP-E RB, 44 XP-G CW, 24 XP-G NW, 12 XP-E Blue.

I have 3 HLG 150H-48B's and 3 ELN 60-48D's on their way to me and will be separating the colors between the drivers but will have to do some parallel strings.

My question is which resistors and fuses should I buy for the XP-G strings where I plan to run them at about 1100ma? I believe the ones mentioned previously by KCRESS are for when you run the string under 1000ma. I could be wrong but would love a link to the right ones at digikey.

Thanks

TheFishMan65

New member

Still 1 ohm, but probably at least 5 watts. Fuses need to go up to to at least 1.1 amps, but probably either 1.25 or 1.5 amps depending on how safe you want to be.

I imagine that this fuse would work: http://search.digikey.com/ca/en/products/02511.25MXL/F2323-ND/700722

But I know that KCRESS is light years ahead of me on this electrical stuff and it's better to ask a dumb question than order the wrong stuff in my opinion.

But I know that KCRESS is light years ahead of me on this electrical stuff and it's better to ask a dumb question than order the wrong stuff in my opinion.

TheFishMan65

New member

Yep, that fuse look good to me. I expect kcress is wondering about using a .1 ohm resistor. Then when you read the voltage across it you have to multiply by 10 (shift the decimal point) to get the true current reading.

miwoodar

Likey the bikey

Great thread(s)! They have been extremely helpful.

I think my design is done but have one lingering question. I want to use a HLG 150-42 to power two parallel strings of 12 XPGs in the 1.0ma range (84 watts, right?). I'm hoping to reserve the extra capacity for another project down the road. I've read that drivers are most efficient when run closer to their rated capacity. My question...am I risking reliability too or am I just wasting a little energy?

I think my design is done but have one lingering question. I want to use a HLG 150-42 to power two parallel strings of 12 XPGs in the 1.0ma range (84 watts, right?). I'm hoping to reserve the extra capacity for another project down the road. I've read that drivers are most efficient when run closer to their rated capacity. My question...am I risking reliability too or am I just wasting a little energy?

- Status

- Not open for further replies.

Similar threads

- Replies

- 39

- Views

- 475

- Replies

- 0

- Views

- 123