Soundwave

New member

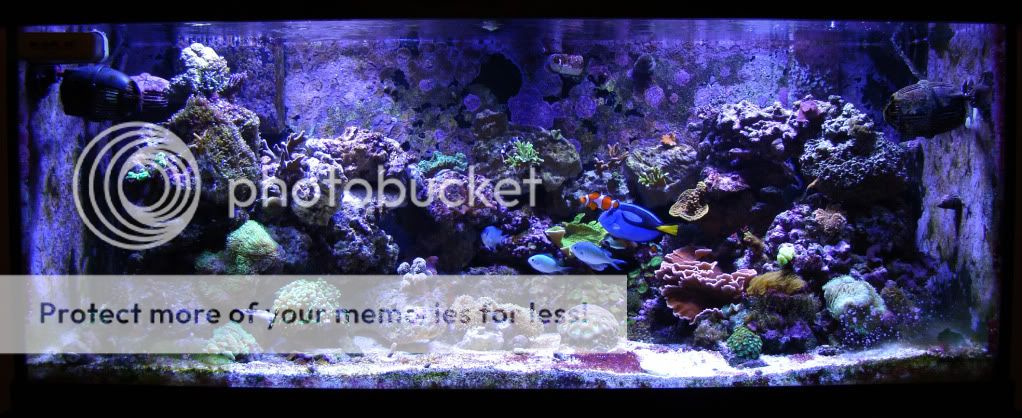

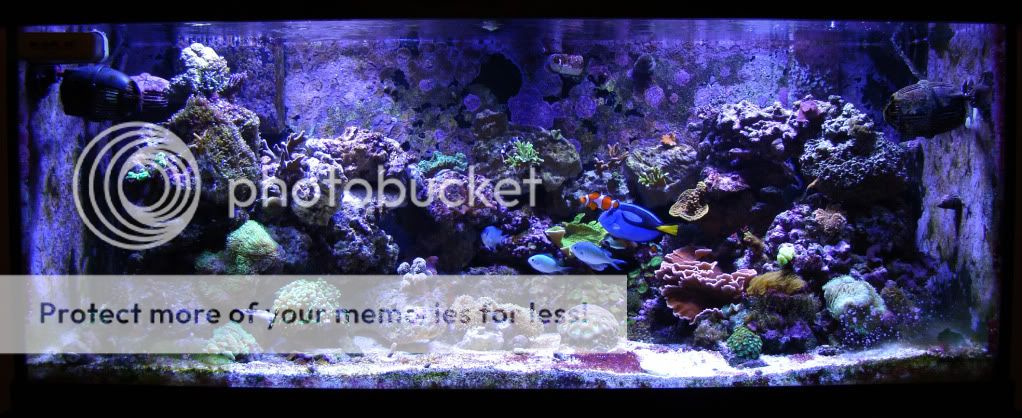

Alrighty. As promised, updated pics.

Please excuse some of the mess. I am battling bryopsis at the moment and I upped my magnesium. I also moved some rock around which disturbed the sandbed. This has created a kind of cascade effect. Mag is killing bryopsis which is putting nutrients into the water which is creating cyano which makes me mad. I'm working on cleaning it up and doing water changes so, hopefully, soon, I'll be back to prettyville.

FTS

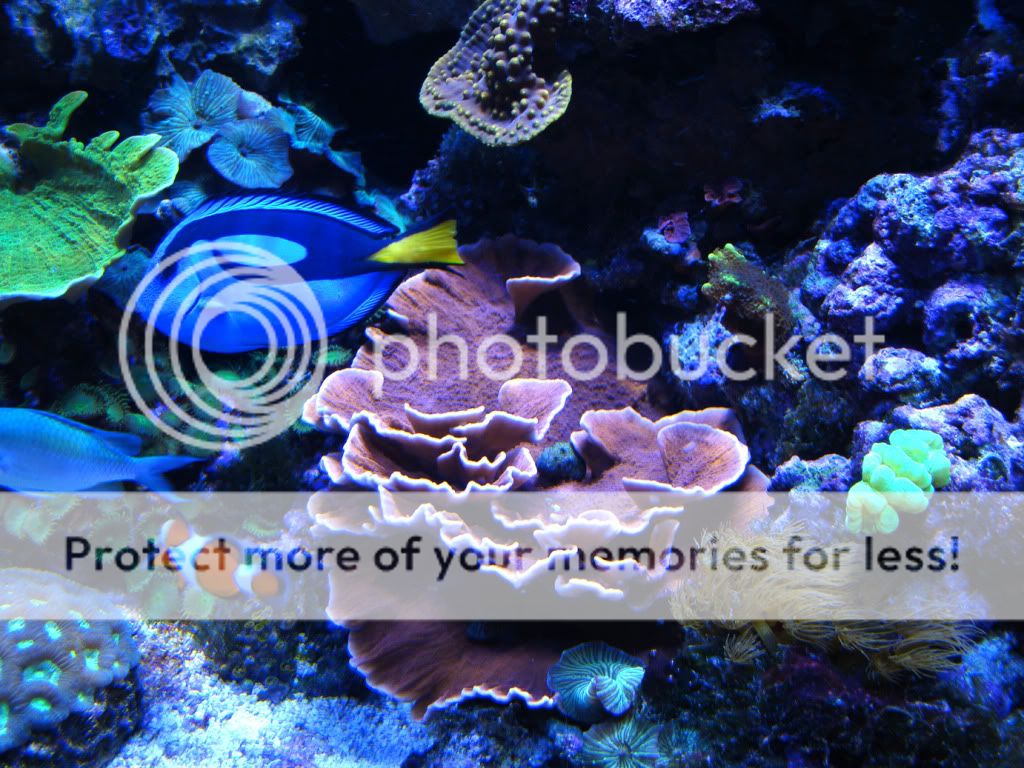

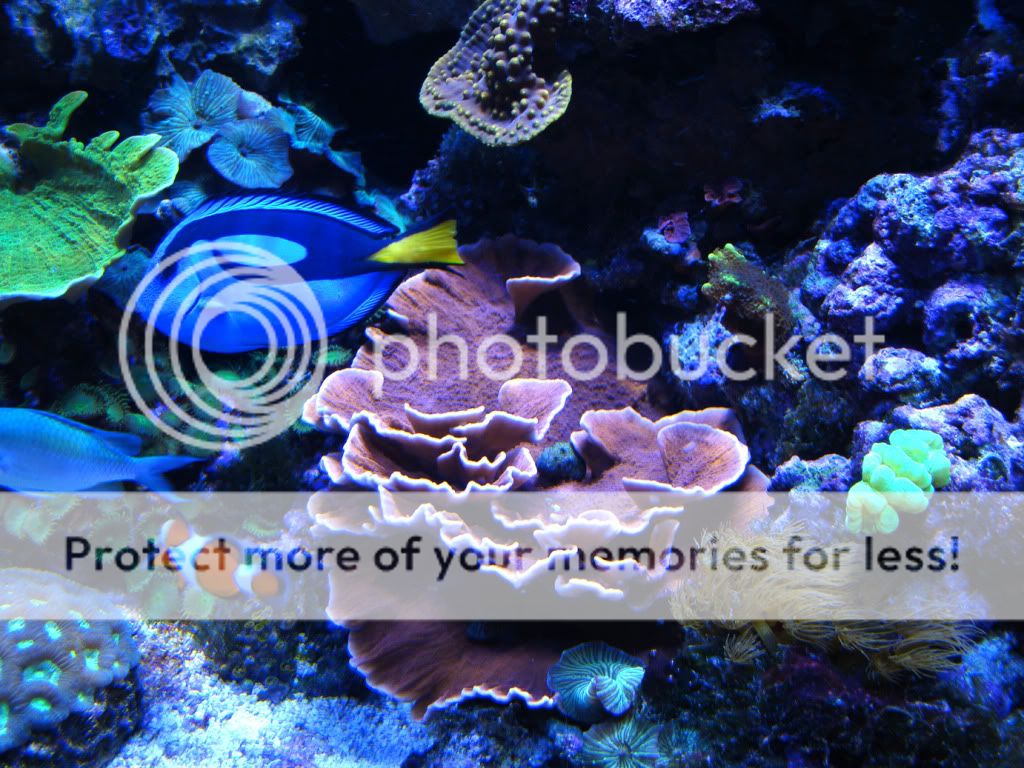

Bonsai

Mix of stuff

Check out the commensal crab!

Purple Digi - I've accidentally broken some arms off it but the growth is still pretty obvious.

Orange/multicolor Digi

Yellow Scroll

Moon

Tri color Acro??? Can't wait to see what this thing does!

Please excuse some of the mess. I am battling bryopsis at the moment and I upped my magnesium. I also moved some rock around which disturbed the sandbed. This has created a kind of cascade effect. Mag is killing bryopsis which is putting nutrients into the water which is creating cyano which makes me mad. I'm working on cleaning it up and doing water changes so, hopefully, soon, I'll be back to prettyville.

FTS

Bonsai

Mix of stuff

Check out the commensal crab!

Purple Digi - I've accidentally broken some arms off it but the growth is still pretty obvious.

Orange/multicolor Digi

Yellow Scroll

Moon

Tri color Acro??? Can't wait to see what this thing does!