Belgian Anthias

New member

Sulfer reactor rate

Sulfer reactor rate

Beste,

In Europe we use the 1% rule. 100Gal system = 1 Gal sulfer. Your reactor must be 1/3 to 1/4 bigger; This means that your reactor must have +-1/3 more volume. Water current through the reactor for a normal bioload ( not heavely skimmed) could be 5x the amount of sulfer per hour. In this case 5 Gal/hour. Max is 10x. But I would put more sulfer when a higher rate is neccesary.

You can put a small bio before the sulferreactor so you are sure all amo and nitri are nitrate before entering the reactor. Put a small bal-flow meter behind the calcium reactors , for easy working and controle, and a flow regulating valve. Mine has a small ozon reactor ( closed skimmer) after the reactor so I aim 100% sure sulfite has no chance and I do not need carbon. If the reactor has no gas outlet, they can leave the system here.

The nitrate in the filtered water will be ZERO.

Mvg

Anthias

Sulfer reactor rate

To determine how much sulfur media you need, you should multiply your total system gallons x .006. For example:

120 gallon system x .006 = .72 liters of media or about ¾ of a liter.

they chopped it up in a quick build in the reefkeeping mag.

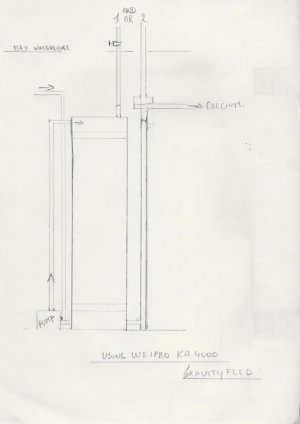

http://reefkeeping.com/issues/2009-01/diy/index.php

they were saying that the MJ1200 is a little too powerfull. but they were using it on 4in PVC so if you use 6 in then it might not be too bad. its a good thing that all MJ have the same output so it wont be hard to swap out a pump and impeller.

Beste,

In Europe we use the 1% rule. 100Gal system = 1 Gal sulfer. Your reactor must be 1/3 to 1/4 bigger; This means that your reactor must have +-1/3 more volume. Water current through the reactor for a normal bioload ( not heavely skimmed) could be 5x the amount of sulfer per hour. In this case 5 Gal/hour. Max is 10x. But I would put more sulfer when a higher rate is neccesary.

You can put a small bio before the sulferreactor so you are sure all amo and nitri are nitrate before entering the reactor. Put a small bal-flow meter behind the calcium reactors , for easy working and controle, and a flow regulating valve. Mine has a small ozon reactor ( closed skimmer) after the reactor so I aim 100% sure sulfite has no chance and I do not need carbon. If the reactor has no gas outlet, they can leave the system here.

The nitrate in the filtered water will be ZERO.

Mvg

Anthias

Last edited: