toomanytanks352

New member

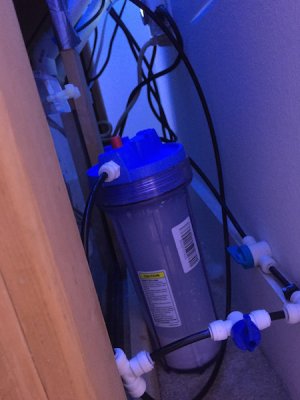

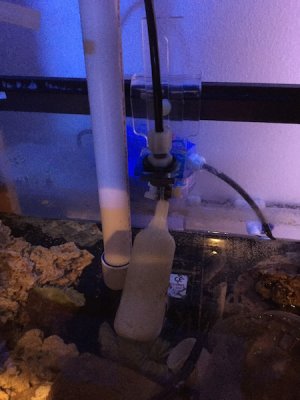

Here is my $40 Kalkwasser reactor that I built and posted on my local marine forum, but thought I'd share it with a broader audience. Enjoy!

http://www.o-r-c-a.org/forum/showthread.php?t=21736

http://www.o-r-c-a.org/forum/showthread.php?t=21736