Thanks Hero.

Well then.. One of our fellow RCers sent me a stack of rare earth magnets to possibly use to hold on/up the ceramic plates.

They're scary strong. They are funny to work with because you just don't realize how strong they are. When you walk by and see one following you around because there's one in your hand it sort gives you chills.

The plan was to either glue them to the back of the ceramic or place them on the front of the ceramic. Either way to shoot thru to a mating magnet on the back of the tank.

I just got a hold of a piece of 3/4" acrylic to check on the hold-up force that would be available from a pair working thru it.

Drum roll....

.

.

.

.

.

.

.

.

No joy.

The sliding force on dry acrylic is only measured as 2.8lbs.

Each plate is about 12lbs... That means I'd need about 5 or 6 pairs for each plate. That would be about 168 magnets. I think we can all agree that's not rational. I'd probably have visitors pinned to the front of the tank due to their pocket knives etc.

Instead I'll use the magnets for the cabinetry.

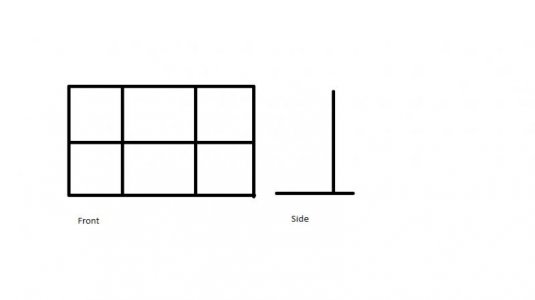

On to the tie wraps. I have various ones that are rated 50lbs each, so two per plate should be plenty.

I was also dreading drilling all those holes in the ceramic as they were taking a lot of pressure and 5-6 minutes each.

After expressing my concern to my ceramics buddy, he whipped out a drill and punched thru a pottery shard in about 5 seconds. He suggested I get a new bit. I did and !! about 10 seconds and little pressure. So today I started drilling them.

Hopefully later today I'll have the first set of three in.