First, please accept my VERY HUMBLE feedback as sincere intent to help. I can appreciate how anxious it might feel to hear critique from some stranger on the west coast! Obviously, my intent is not to criticize, but to help. Also, I know many out there are very very experienced, and I do not profess to know more any others. Perhaps some out there are having success with similar designs, and I definately respect that. And in fact, I bet there is a structural engineer or two out there as well with experience in field.

After feeling some guilt since my post last night, I have decided the least I can do is offer a solution, but first, I have a question: Did you notice your lower cabinet doors suffer misalignment and/or difficulty to open/close immediately upon loading with water? I would predict you would have noticed something different right away ... but perhaps this is not the case?

Regardless, IF you feel you may wish to bolster your frame, then your setup seems suitable to accept a fairly simple retrofit, as follows:

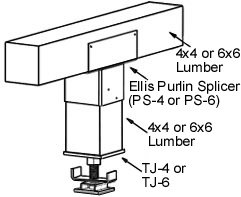

Consider a new support, with special attention for installation on a system which is already under full load and deflecting. Obviously, if you could magically go back to the day before your tank arrived (during that snow storm for example) you could simply add a pair of 4x4 columns. But since you are "œin the wet" I suggest including 4x4 columns including screw jacks (

http://www.ellisok.com/ellisok/timberjackproducts_screwjacks.html):

The concept is shown on the attached but I recommend two columns, one on each end. And of course the horizontal 4x4 should support your midspan member seems very well positions (and fastened to the adjoining longitudinal 2x4s). Obviously, all of this will add some congestion (but not much actually?) to your lower cabinet. I worry about the ability to shoehorn in the new support to bear under the longitudinal 2x4 which is on the front of your cabinet; will it work?

I suggest some sort of plywood platform at bottom which is anchors/screwed in place to assure no sliding, and then screw/bolt the screw jacks (I guess you could bolt the bottom plates of the timber jacks to your nice wood floor as well!). You must of course mitigate for Murphy's Law by adding fasters adequately across your retrofit. If possible, I drain what you can (partial seems just fine) prior to jacking up the midspan. That can be precarious because it's very difficult to understand just how much upward load you are applying as you screw up the timber jacks. You're probably going to apply say 1000 lbs upward force at the middle (that is on a total system weight of perhaps 3000 lbs, is that right?) Excessive upward load would be very very bad. If you are not comfortable, then practice jacking up (somehow) before showtime.

Also crvz: As you consider a frame consisting of 2x8 horizontal members, consider means to support in the "œweak axis" over such a long span. In earthquakes, the girders in your basement wish to rotate about the weak axis to releave the excess load, thus we install blocking or double-diagonal bracing to address such. Whatever you decide, mid-span vertical support is my recommendation on any system longer than say 4 feet. Again, there are experts out there with A LOT more hands on experience than I, but this is some 2 cents worth for design consideration.