You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Neptune Apex web interface compatible DIY reef controller

- Thread starter d0ughb0y

- Start date

WaterMagnet

New member

Pump

Pump

Hi,

Can anyone tell me the purpose of Pump on outlet 4? I am assuming the WP25s are both switched off from outlet 1 so I am confused as to the purpose of outlet 4.

Of course this can be used for another Pump but I'm not 100% sure.

Please confirm.

Thanks

Pump

Hi,

Can anyone tell me the purpose of Pump on outlet 4? I am assuming the WP25s are both switched off from outlet 1 so I am confused as to the purpose of outlet 4.

Of course this can be used for another Pump but I'm not 100% sure.

Please confirm.

Thanks

WaterMagnet

New member

20 and 21 on top right.

Sent from my iPhone using Tapatalk

Thanks cjmdh.

Although I have since discovered that I can use the ones on the top left also.

Thanks.

d0ughb0y

Active member

Hi,

Can anyone tell me the purpose of Pump on outlet 4? I am assuming the WP25s are both switched off from outlet 1 so I am confused as to the purpose of outlet 4.

Of course this can be used for another Pump but I'm not 100% sure.

Please confirm.

Thanks

That is for an mj1200 pump placed at the bottom of my overflow that comes on for 15 minutes every hour or 3 hours I can't remember the exact timing to kick up detritus that settles at the bottom of the overflow. You can remove this or use the outlet for something else.

d0ughb0y

Active member

update on the v2 controller.

I just updated the esp8266 firmeare to the latest and tested and verified SSL now actually works. I am able to send email via my Gmail account. I think this is a big step up.

There is a catch though, it only works with mail servers supporting SMTPS or port 465. A lot of other mail servers I tried that claims to support port 465 does not actually support them anymore, like comcast, and yahoo. They use port 587 and requires STARTTLS which ESP8266 does not support. I think if it works with Gmail, then that is good enough, as I think most people have gmail account or can get one. You do have to allow non standard app login in your google account security page.

I know the classic apex does not support SSL, and I did not see any mention of ssl support in the new Apex.

karimw confirmed the brushless motor controller module works with the DCT pump. I have yet to set mine up. I just needed a confirmation to make sure that the new controller will work with the new generation of DC and cross flow pumps. I think I will be able to place the pcb order by the end of June.

I just updated the esp8266 firmeare to the latest and tested and verified SSL now actually works. I am able to send email via my Gmail account. I think this is a big step up.

There is a catch though, it only works with mail servers supporting SMTPS or port 465. A lot of other mail servers I tried that claims to support port 465 does not actually support them anymore, like comcast, and yahoo. They use port 587 and requires STARTTLS which ESP8266 does not support. I think if it works with Gmail, then that is good enough, as I think most people have gmail account or can get one. You do have to allow non standard app login in your google account security page.

I know the classic apex does not support SSL, and I did not see any mention of ssl support in the new Apex.

karimw confirmed the brushless motor controller module works with the DCT pump. I have yet to set mine up. I just needed a confirmation to make sure that the new controller will work with the new generation of DC and cross flow pumps. I think I will be able to place the pcb order by the end of June.

d0ughb0y

Active member

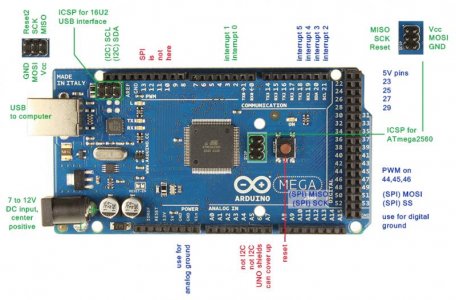

I plan to replace the arduino mega with the new board in my chauvet. That's why I made sure it is the same size (or close to it).

If you already built the arduino mega version, then you can probably retrofit it to use the new board.

using chauvet is not required. besides, the original chauvet has been discontinued, and I think american dj makes them now, but the price is too high. I think most people just build their own outlet box.

If you already built the arduino mega version, then you can probably retrofit it to use the new board.

using chauvet is not required. besides, the original chauvet has been discontinued, and I think american dj makes them now, but the price is too high. I think most people just build their own outlet box.

d0ughb0y

Active member

there is no list. I want to complete the project first.

All info will be available so anyone can diy using equivalent through hole components.

Assembly of hardware is not hard, except for soldering the pins to pads under the teensy. I'm not sure yet how that can be simplified. If you are building your own board, you can use this adapter board

https://www.tindie.com/products/loglow/teensy-32-breakout/?pt=full_prod_search

fully assembled (including crsytal for RTC) costs $55 shipped though, considering the teensy itself costs about $20, $35 for the board and labor to assemble is probably not too bad.

All info will be available so anyone can diy using equivalent through hole components.

Assembly of hardware is not hard, except for soldering the pins to pads under the teensy. I'm not sure yet how that can be simplified. If you are building your own board, you can use this adapter board

https://www.tindie.com/products/loglow/teensy-32-breakout/?pt=full_prod_search

fully assembled (including crsytal for RTC) costs $55 shipped though, considering the teensy itself costs about $20, $35 for the board and labor to assemble is probably not too bad.

WaterMagnet

New member

Controller Setup - Macros and Actions

Controller Setup - Macros and Actions

Hi,

Can anyone please explain the use of Macros and Actions.

Currently the Macros have 4 default types:

1) Feed Now (Disabled)

2) Feed (Auto)

3) All Pumps On (Disabled)

4) All Pumps Off (Disabled)

Actions:

1) Feed Now

Im an not sure about the correlation between the two.

What is the Outlet number, Init Off an On Time?

Sorry for all the questions but I having read all posts I still haven't grasped their purpose.

Maybe the following will help.

My objective is to run a feeder using this controller.

I will not be switching off pumps or wave pumps during the feeding process.

My feeding schedule will be at 10am and 5pm and I will be rotating the feeder once in both these times.

How do I set the actions and macros to reflect this?

Thanks in advance.

Controller Setup - Macros and Actions

Hi,

Can anyone please explain the use of Macros and Actions.

Currently the Macros have 4 default types:

1) Feed Now (Disabled)

2) Feed (Auto)

3) All Pumps On (Disabled)

4) All Pumps Off (Disabled)

Actions:

1) Feed Now

a) Feeder - Outlet:20 / Init Off:5 / On Time:1

2) Feed a) Feeder - Outlet:20 / Init Off:30 / On Time:1

b) Return - Outlet:7 / Init Off:150 / On Time:90

c) Jebao - Outlet: 30 / Init Off:240 / On Time:0

3) All Pumps On b) Return - Outlet:7 / Init Off:150 / On Time:90

c) Jebao - Outlet: 30 / Init Off:240 / On Time:0

a) WPs - Outlet:0 / Init Off:0 / On Time:600

b) Jebao - Outlet:30 / Init Off:600 / On Time:0

4) All Pumps Offb) Jebao - Outlet:30 / Init Off:600 / On Time:0

a) WPs - Outlet:0 / Init Off:600 / On Time:0

Im an not sure about the correlation between the two.

What is the Outlet number, Init Off an On Time?

Sorry for all the questions but I having read all posts I still haven't grasped their purpose.

Maybe the following will help.

My objective is to run a feeder using this controller.

I will not be switching off pumps or wave pumps during the feeding process.

My feeding schedule will be at 10am and 5pm and I will be rotating the feeder once in both these times.

How do I set the actions and macros to reflect this?

Thanks in advance.

WaterMagnet

New member

After reading a few posts I am beginning to now understand the relationship between macros and actions.

The only thing I would like clarification on is the understanding of the Outlet Definition.

In the Chauvet16.ino file we have the following enum:

enum outlet {OUTLETDEFS, Feeder=20, Doser0=23, Doser1=24, Doser2=25, Doser3=26, Pump0=30, Pump1=31, Pump2=32, Pump3=33, PWMFan0=40, PWMFan1=41, PWMFan2=42, End=255};

Does this mean that if I was to refer to the Feeder outlet in my Macros and Actions I need to refer to the Outlet 20?

What does the 20 mean?

Thanks

The only thing I would like clarification on is the understanding of the Outlet Definition.

In the Chauvet16.ino file we have the following enum:

enum outlet {OUTLETDEFS, Feeder=20, Doser0=23, Doser1=24, Doser2=25, Doser3=26, Pump0=30, Pump1=31, Pump2=32, Pump3=33, PWMFan0=40, PWMFan1=41, PWMFan2=42, End=255};

Does this mean that if I was to refer to the Feeder outlet in my Macros and Actions I need to refer to the Outlet 20?

What does the 20 mean?

Thanks

d0ughb0y

Active member

20 is just a code defined for the label Feeder.

as to outlet programming, think of it as defining a cycle. All cycles start at midnight. So if you want an outlet to change twice a day, you define a cycle that is 12 hours. If you want an outlet to change 4 times a day, you define a cycle that is 6 hours. If you want it to change once a day, you define a 24 hour cycle.

a cycle is made up of Initial off time + On Time + off time = cycle time

so if you want something on for 24 hours, init off time = 0, on time = 24 hrs, off time =0.

A macro is simply the above principle, think of it as an outlet program inside an outlet program. For a macro, the cycle time would be the same as outlet cycle time, except the ON time, you are not turning on outlet, but you are executing Actions. So if your macro ON time is 15 minutes, then you define actions that will complete in 15 minutes.

as to outlet programming, think of it as defining a cycle. All cycles start at midnight. So if you want an outlet to change twice a day, you define a cycle that is 12 hours. If you want an outlet to change 4 times a day, you define a cycle that is 6 hours. If you want it to change once a day, you define a 24 hour cycle.

a cycle is made up of Initial off time + On Time + off time = cycle time

so if you want something on for 24 hours, init off time = 0, on time = 24 hrs, off time =0.

A macro is simply the above principle, think of it as an outlet program inside an outlet program. For a macro, the cycle time would be the same as outlet cycle time, except the ON time, you are not turning on outlet, but you are executing Actions. So if your macro ON time is 15 minutes, then you define actions that will complete in 15 minutes.

WaterMagnet

New member

20 is just a code defined for the label Feeder.

as to outlet programming, think of it as defining a cycle. All cycles start at midnight. So if you want an outlet to change twice a day, you define a cycle that is 12 hours. If you want an outlet to change 4 times a day, you define a cycle that is 6 hours. If you want it to change once a day, you define a 24 hour cycle.

a cycle is made up of Initial off time + On Time + off time = cycle time

so if you want something on for 24 hours, init off time = 0, on time = 24 hrs, off time =0.

A macro is simply the above principle, think of it as an outlet program inside an outlet program. For a macro, the cycle time would be the same as outlet cycle time, except the ON time, you are not turning on outlet, but you are executing Actions. So if your macro ON time is 15 minutes, then you define actions that will complete in 15 minutes.

Thanks d0ughb0y, the explanation of how the macros and actions work now make perfect sense.

As for the outlet number are you saying that if I want to refer to Pump0 in my macro/actions I would set Outlet value to 30?

dudedudedude

Member

d0ughb0y,

Any preview of what the lighting LED interface is going to look like?

Any preview of what the lighting LED interface is going to look like?

d0ughb0y

Active member

I have not done any html/javascript code for the LED interface yet. But it will be similar to the original chauvet, but using the latest jquery mobile version. I think the new interface thing is the sliding menu, the html page will definitely use sliding menus.

I will be working on the chauvet v2 software first though, and then later go back to the LED software.

I will be working on the chauvet v2 software first though, and then later go back to the LED software.

theatrus

100-mile-commuter

From my experience, most PCB proto places frown on multi-project panels, but will happily panelize an order for you.

Most budget shops would likely V-score this board and not do a routing step if there is enough ordered for a whole panel, since it's purely rectangular with no slots. You don't end up with rat bites but the edges are rougher - nothing a belt sander won't fix if you want a smooth edged board.

Most budget shops would likely V-score this board and not do a routing step if there is enough ordered for a whole panel, since it's purely rectangular with no slots. You don't end up with rat bites but the edges are rougher - nothing a belt sander won't fix if you want a smooth edged board.

Similar threads

- Replies

- 0

- Views

- 1K

- Replies

- 1

- Views

- 673

- Replies

- 0

- Views

- 976