SimonSKL

New member

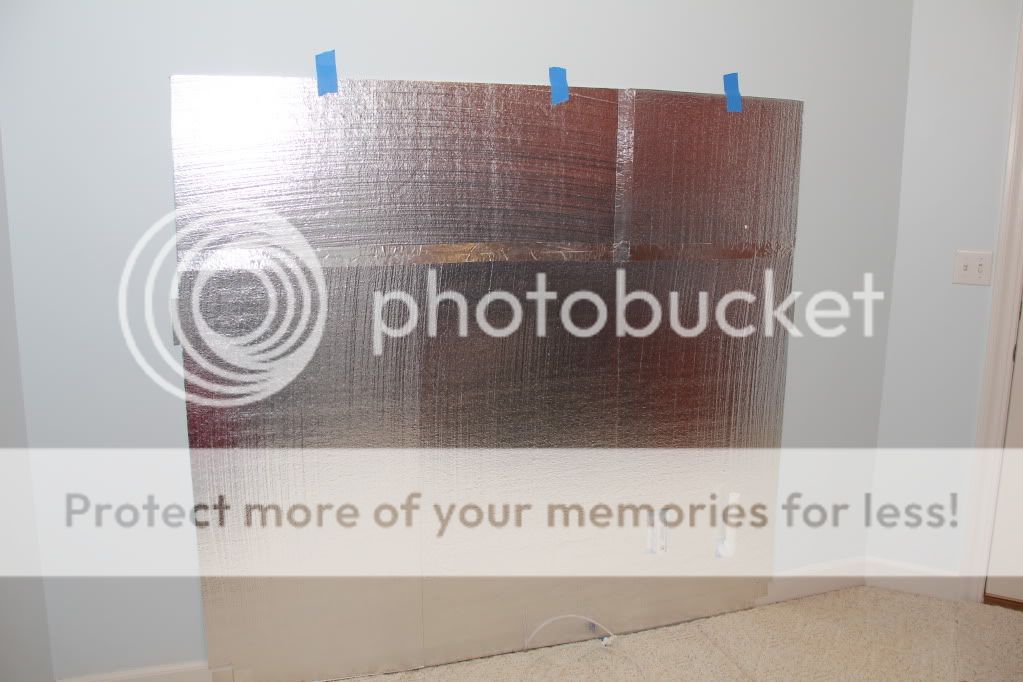

I made a little progress today. Here is a picture of my new tank. I just love the black silicone that they use in this tank, not the clear stuff. The 30g sump is just behind it. I can't find any one in town to drill a 1 3/4" hole for me so I am ordering a 45mm diamond drill bit from BRS and DIY. This will be a first for me:worried2:

This is one of the two plumbing kits that comes with the corner-flo: the drain is 1.5" and the return is 1". I wish they didn't glue the standpipes to the bulkheads.

I finished painting my "fish" room, aka office and ran a drain line to the utility closet drain for water changes.

Tonight I started building the stand. These are the four legs of the stand made with Douglas fir 4x4. Douglas fir is one of the strongest softwood. The cuts are a little complicated and I have to be careful in not making the wrong cut.

I also talked to someone in the long Failsafe Bean Animal thread and decided to make yet another change to my plumbing configuration. Hopefully this will be the final plan.

Green - full siphon

Purple - open channel

Blue - Failsafe or emergency drain

Red - Return

:bounce3:

:bounce3:

This is one of the two plumbing kits that comes with the corner-flo: the drain is 1.5" and the return is 1". I wish they didn't glue the standpipes to the bulkheads.

I finished painting my "fish" room, aka office and ran a drain line to the utility closet drain for water changes.

Tonight I started building the stand. These are the four legs of the stand made with Douglas fir 4x4. Douglas fir is one of the strongest softwood. The cuts are a little complicated and I have to be careful in not making the wrong cut.

I also talked to someone in the long Failsafe Bean Animal thread and decided to make yet another change to my plumbing configuration. Hopefully this will be the final plan.

Green - full siphon

Purple - open channel

Blue - Failsafe or emergency drain

Red - Return