Progress on Sunday:

Plumbing 95% completed and started on the wiring :celeb3:

In the pictures below we got the drain lines all in place first for the herbie drain first. Only two holes in each overflow so no bean animal on this tank sadly, but will be in the plans for my future 500+ gallon custom build.

*WAIT did I just say that....lets get water in this one first*

We then built the manifold for the returns, and to run a BRS dual reactor. Once we got the manifold mounted in the stand and hooked up to the Reef Octopus DC10500 return pump we proceeded to plumb the the return lines to the tank. This tank will have dual 3/4" return lines over the back of the tank running into split line-loc's. Just need to put in a few pipe hangers I need to go purchase yet to secure everything, and the plumbing will be 100% complete.

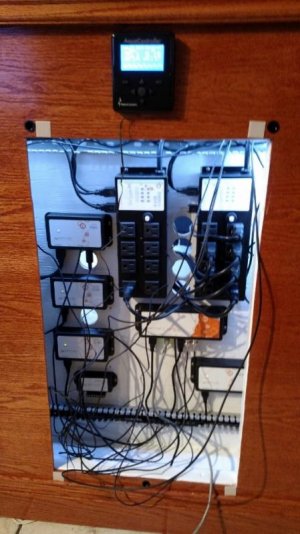

My helper through the whole project (Dad) left for the day and I spent the next few hours hanging the pumps for dosing, ATO, water change, and started running the wiring. It has been a long but very productive weekend and I am very close now to water and a leak test!

Plumbing 95% completed and started on the wiring :celeb3:

In the pictures below we got the drain lines all in place first for the herbie drain first. Only two holes in each overflow so no bean animal on this tank sadly, but will be in the plans for my future 500+ gallon custom build.

*WAIT did I just say that....lets get water in this one first*

We then built the manifold for the returns, and to run a BRS dual reactor. Once we got the manifold mounted in the stand and hooked up to the Reef Octopus DC10500 return pump we proceeded to plumb the the return lines to the tank. This tank will have dual 3/4" return lines over the back of the tank running into split line-loc's. Just need to put in a few pipe hangers I need to go purchase yet to secure everything, and the plumbing will be 100% complete.

My helper through the whole project (Dad) left for the day and I spent the next few hours hanging the pumps for dosing, ATO, water change, and started running the wiring. It has been a long but very productive weekend and I am very close now to water and a leak test!