AZRippster

Diver & Reef Aquarium Nut

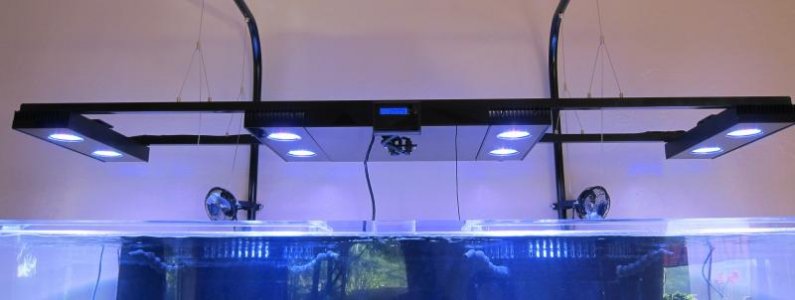

Thought I would share with any of you Tucson/Sierra Vista DIY'ers my RapidLED Aurora build I finally finished this weekend. These are truly awesome and basically the Ecotech Radion Pro 30. I decided on using the Coralux Storm X controller because Neptune Systems do not have a PWM module "yet" for us DIY'ers. It would have been nice to tie in the fixture into my Apex but I do have to say the Storm X is a very nice unit and Ben is amazing in his prompt responses to any questions you may have. So, if you don't want to put out "allota dough" for Radions, you'll love these.