DasCamel

Active member

Plumbing design.

Plumbing design.

http://www.dursostandpipes.com/

Many ways to connect the drain pipes, if done right Durso works fine. I'm a noise freak and the tank is in the living room. They have detailed instructions on how to build them but I decided just to purchase in advance. I went for 29" high, could have had 30" high but I like hearing the slight trickle of water into the overflow. I went with 1" PVC everywhere, except the standpipes themselves which start at a larger diameter and get smaller to fit the 1" bulkhead to help silence the flow. If you want really high flow, do not use Durso, the water draining in the pipes and into the sump will get louder. Having two drains is key, they back each other up to blockages + reducing noise. Very good idea to check each side monthly to make sure nothing goes in. I don't see how, guess it "could" happen.

Be sure to place unions frequently to be able to break things apart for cleaning and maintenance. Also, do not place anything close to the bulkheads. Give yourself room to cut PVC pipe and rejoin/repair under the bulkhead. Or just to get tools by. I placed valves under both drains and the return to easily shut water off for whatever reason, really only need a valve on the return pump section. The valves cost a little more but also function as unions.

Also, do to the pressures involved really don't need PVC primer, but still use it. It makes the piping slightly softer and easier to push and turn in to create that perfect pipe seal with the primer and blue cement. YouTube is also great for this. Takes a second to apply, well worth it in the long run. Gotta say, had a blast with all the piping, went smoothly. PVC pipe cutter is well worth its wait in gold. I had good luck with Lowes with some of the parts, but Marine Depot and other sites were very helpful.

Only thing I'm going to change, is using a piece of flex PVC directly from the return pump to the first Valve/union. Why? Although the Sicce 5.0 is very silent, with everything hard plumbed the vibration of the pump gets transferred down the pipe to the bulkhead, to the tank and thus to the stand and walls. Regular noise can be dampened, vibration gets past everything causing a resonance in the walls. Very annoying, and again I hate buzzing random noise. Little water trickle, I'm cool with. My entire wall slightly vibrating, not so much.

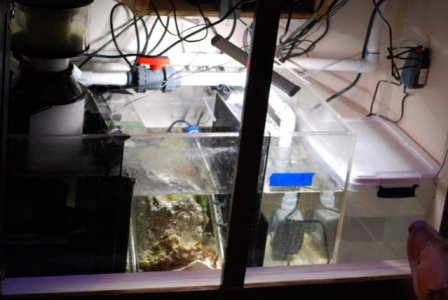

Picture time! Third pic shows how little space we left for access. Such a pain. Last pic is my hand after the fun with the punch tool. Ah, the memories.

-Das

Plumbing design.

http://www.dursostandpipes.com/

Many ways to connect the drain pipes, if done right Durso works fine. I'm a noise freak and the tank is in the living room. They have detailed instructions on how to build them but I decided just to purchase in advance. I went for 29" high, could have had 30" high but I like hearing the slight trickle of water into the overflow. I went with 1" PVC everywhere, except the standpipes themselves which start at a larger diameter and get smaller to fit the 1" bulkhead to help silence the flow. If you want really high flow, do not use Durso, the water draining in the pipes and into the sump will get louder. Having two drains is key, they back each other up to blockages + reducing noise. Very good idea to check each side monthly to make sure nothing goes in. I don't see how, guess it "could" happen.

Be sure to place unions frequently to be able to break things apart for cleaning and maintenance. Also, do not place anything close to the bulkheads. Give yourself room to cut PVC pipe and rejoin/repair under the bulkhead. Or just to get tools by. I placed valves under both drains and the return to easily shut water off for whatever reason, really only need a valve on the return pump section. The valves cost a little more but also function as unions.

Also, do to the pressures involved really don't need PVC primer, but still use it. It makes the piping slightly softer and easier to push and turn in to create that perfect pipe seal with the primer and blue cement. YouTube is also great for this. Takes a second to apply, well worth it in the long run. Gotta say, had a blast with all the piping, went smoothly. PVC pipe cutter is well worth its wait in gold. I had good luck with Lowes with some of the parts, but Marine Depot and other sites were very helpful.

Only thing I'm going to change, is using a piece of flex PVC directly from the return pump to the first Valve/union. Why? Although the Sicce 5.0 is very silent, with everything hard plumbed the vibration of the pump gets transferred down the pipe to the bulkhead, to the tank and thus to the stand and walls. Regular noise can be dampened, vibration gets past everything causing a resonance in the walls. Very annoying, and again I hate buzzing random noise. Little water trickle, I'm cool with. My entire wall slightly vibrating, not so much.

Picture time! Third pic shows how little space we left for access. Such a pain. Last pic is my hand after the fun with the punch tool. Ah, the memories.

-Das