You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

~360 In Wall Build

- Thread starter Raoul5Duke

- Start date

Raoul5Duke

Active member

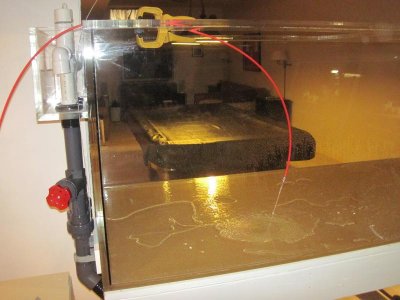

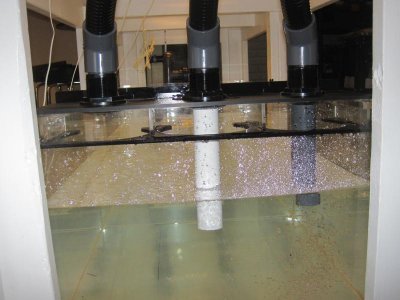

Tank, Sump & Skimmer

Tank, Sump & Skimmer

I'm a little crunched for time this a.m. but I wanted to post the few remaining pictures I have and hopefully later I can provide some details. I'm heading to Aquatica this weekend to pick up more equipment, so hopefully I can start on some plumbing Sun.

JNS Shark 7 Skimmer

Sump

Tank

Thanks for the questions & suggestions guys.

Tank, Sump & Skimmer

I'm a little crunched for time this a.m. but I wanted to post the few remaining pictures I have and hopefully later I can provide some details. I'm heading to Aquatica this weekend to pick up more equipment, so hopefully I can start on some plumbing Sun.

JNS Shark 7 Skimmer

Sump

Tank

Thanks for the questions & suggestions guys.

Raoul5Duke

Active member

Did you use 2x6's or 2x8's for the top of the stand?

I used 2x6s since there was a brace in the middle. It basically ends up being 2 4ft. spans instead of 1 8ft. span. RocketEngineer said I could even go with 2x4s for the legs, but I wanted to make sure it was overbuilt given the size so I used 2x6s in the corners and 2x4s for the center supports.

Raoul5Duke

Active member

Great build! Thanks again for the coral, they are looking good. Are you running your new beast of a skimmer in sump or external?

No problem, I'm glad to have the extra space. I'm running it in sump. I debated about going external but in the end felt like it would take up too much space and the idea of it overflowing onto the floor if it were external wasn't too appealing.

Raoul5Duke

Active member

Tank looks great! How long till it's wet?

Honestly, I'm not sure. With a wife, 4 kids, work and coaching its tough to find the time. I also want to go slow and make sure its done right. My end goal is that its easier to maintain through automation even though its a much bigger system.

Raoul5Duke

Active member

First Minor Mistake

First Minor Mistake

So after getting the tank and sump on the stand I realized that the only way to fit the skimmer body into the sump is to slide the sump partially out of the stand. I accounted for the size when we built the sump and the height of the stand, but I didn't realize the diameter of the skimmer was so large it couldn't be angled into the space between the sump and stand. Once its in the fit is great, plenty of room to access the pumps and remove the top for cleaning.

I think in the end it will be fine, I just need to make sure there is enough space and easy disconnects with unions so that I can slide it out if I ever need to remove the body. I'm guessing this might only be needed very rarely as long as the skimmer works well.

First Minor Mistake

So after getting the tank and sump on the stand I realized that the only way to fit the skimmer body into the sump is to slide the sump partially out of the stand. I accounted for the size when we built the sump and the height of the stand, but I didn't realize the diameter of the skimmer was so large it couldn't be angled into the space between the sump and stand. Once its in the fit is great, plenty of room to access the pumps and remove the top for cleaning.

I think in the end it will be fine, I just need to make sure there is enough space and easy disconnects with unions so that I can slide it out if I ever need to remove the body. I'm guessing this might only be needed very rarely as long as the skimmer works well.

benihana

New member

Honestly, I'm not sure. With a wife, 4 kids, work and coaching its tough to find the time. I also want to go slow and make sure its done right. My end goal is that its easier to maintain through automation even though its a much bigger system.

I hear you on every account....I am still well into the planning stages for mine, and trying to think of everything that I didn't like doing, and how I can automate it

I wouldn't worry too much about your skimmer, like you said, as long as you are good about using unions so you can essentially take you sump off line, you should be ok.....it won't be fun, but should be ok

I guess the other option is to disassemble the stand, and increase the height of the legs so that you are able to get the skimmer in and out easily, so if there ever was an issue with it you wouldn't have to drin your sump to get it out.......

Raoul5Duke

Active member

I hear you on every account....I am still well into the planning stages for mine, and trying to think of everything that I didn't like doing, and how I can automate it

I wouldn't worry too much about your skimmer, like you said, as long as you are good about using unions so you can essentially take you sump off line, you should be ok.....it won't be fun, but should be ok

I guess the other option is to disassemble the stand, and increase the height of the legs so that you are able to get the skimmer in and out easily, so if there ever was an issue with it you wouldn't have to drin your sump to get it out.......

At this point changing the stand is really not a viable option. If necessary down the road I can look into a different skimmer if needed, but given the size of the neck opening I think I can still get in there and clean it if needed.

The more I look into it I think I am going to take your advice and install some sort of exhaust fan. There is a window in the back I can vent it out of for now. If it works well I can have a dryer vent permanently installed or drill the side of the house for a vent. I'm trying to see if anyone makes a panel that slides into windows for venting dryers or ac units. No luck so far.

benihana

New member

The more I look into it I think I am going to take your advice and install some sort of exhaust fan. There is a window in the back I can vent it out of for now. If it works well I can have a dryer vent permanently installed or drill the side of the house for a vent. I'm trying to see if anyone makes a panel that slides into windows for venting dryers or ac units. No luck so far.

If you are going to go this route, then I would just get some 1/2" plywood and cut it to fit the window opening

In the long run, I think you will be better off venting it out through the house though

Raoul5Duke

Active member

Weekend Progress....

Weekend Progress....

It was a pretty busy weekend for the family so I didn't get too much accomplished. Drove down to Aquatica Sat. morning and picked up a bunch of equipment which included 4x Radion G3 Pros, 2x MP60s, a Reeflink (for 50% off due to a recent promotion) :bounce2: 2x Reeflo Dart Gold pumps and a bunch of miscellaneous plumbing parts.

On Sunday I ran up to Lowe's and picked up some lumber to frame around the sink and for 1 of the 40 gallon breeder stands I will need. I plan on having 1 40-gallon for a frag tank and another for a QT tank. I got the wood cut and got most of the sink framed in.

That's it for now. I hope to post of few pics up tonight when I get home from work.

Weekend Progress....

It was a pretty busy weekend for the family so I didn't get too much accomplished. Drove down to Aquatica Sat. morning and picked up a bunch of equipment which included 4x Radion G3 Pros, 2x MP60s, a Reeflink (for 50% off due to a recent promotion) :bounce2: 2x Reeflo Dart Gold pumps and a bunch of miscellaneous plumbing parts.

On Sunday I ran up to Lowe's and picked up some lumber to frame around the sink and for 1 of the 40 gallon breeder stands I will need. I plan on having 1 40-gallon for a frag tank and another for a QT tank. I got the wood cut and got most of the sink framed in.

That's it for now. I hope to post of few pics up tonight when I get home from work.

Raoul5Duke

Active member

Raoul5Duke

Active member

Updates

Updates

Well, I thought I was going to be out of town this past weekend but those plans got canceled so I was able to get some more work accomplished.

I finished the 2x 40-breeder stands I needed and I finished framing around the sink including a cover for the plumbing and a counter to use when I am cleaning items.

I received most of my plumbing, but the black spaflex has yet to arrive so I can't get much done on the plumbing yet.

I also received my aluminum extrusion parts from 80/20 inc. and was able to get most of my light rack completed.

View attachment 277406

More on the light rack in the next post as I have reached my maximum # of pics.

Updates

Well, I thought I was going to be out of town this past weekend but those plans got canceled so I was able to get some more work accomplished.

I finished the 2x 40-breeder stands I needed and I finished framing around the sink including a cover for the plumbing and a counter to use when I am cleaning items.

I received most of my plumbing, but the black spaflex has yet to arrive so I can't get much done on the plumbing yet.

I also received my aluminum extrusion parts from 80/20 inc. and was able to get most of my light rack completed.

View attachment 277406

More on the light rack in the next post as I have reached my maximum # of pics.

Raoul5Duke

Active member

Radion Hanging Solution

Radion Hanging Solution

So after doing some searching I found a couple of threads where people had used aluminum extrusion to make rail kits that allowed their radions to be adjustable. I copied a few of those designs and ordered what I thought I needed from 80/20 inc. Here is the result:

View attachment 277410

View attachment 277411

I want to make a few adjustments, including adding a third cable for support, before I hang the other two lights. I plan on hanging the power supply boxes above the lights on the wall so all the wires will be out of the way.

Radion Hanging Solution

So after doing some searching I found a couple of threads where people had used aluminum extrusion to make rail kits that allowed their radions to be adjustable. I copied a few of those designs and ordered what I thought I needed from 80/20 inc. Here is the result:

View attachment 277410

View attachment 277411

I want to make a few adjustments, including adding a third cable for support, before I hang the other two lights. I plan on hanging the power supply boxes above the lights on the wall so all the wires will be out of the way.

Raoul5Duke

Active member

Updates

Updates

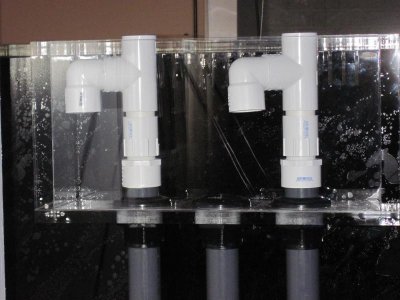

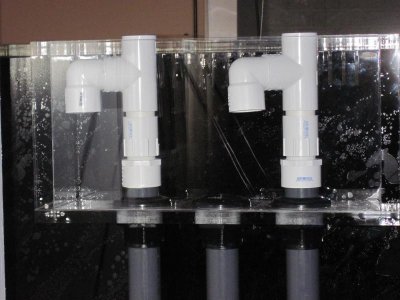

Well, I managed to plumb the overflow side of the tank this weekend. This proved to be challenging as I tried to overcomplicate the design, but I eventually go it done. One problem I have run into is that the overflow box is too small to hold 3x 1.5" dursos so I am going to try 1.25" dursos to see if they will fit or I will need to go with stockman standpipes since they take up less space. Accord to some of the charts I have seen a 1.25" drain can handle 1,500 gph so 3x of them will still handle the max a Reeflo Dart can push. Not a major problem, just more time to find the fix and order the parts. Its frustrating, but continues to move along. I will post some photos this evening.

Updates

Well, I managed to plumb the overflow side of the tank this weekend. This proved to be challenging as I tried to overcomplicate the design, but I eventually go it done. One problem I have run into is that the overflow box is too small to hold 3x 1.5" dursos so I am going to try 1.25" dursos to see if they will fit or I will need to go with stockman standpipes since they take up less space. Accord to some of the charts I have seen a 1.25" drain can handle 1,500 gph so 3x of them will still handle the max a Reeflo Dart can push. Not a major problem, just more time to find the fix and order the parts. Its frustrating, but continues to move along. I will post some photos this evening.

Raoul5Duke

Active member

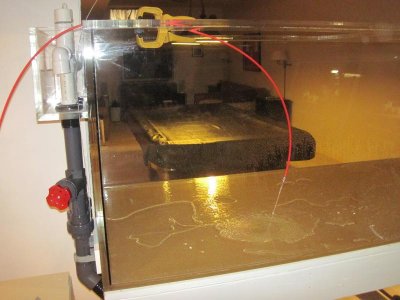

Pics

Pics

Plumbing of the overflow side completed

I used the unions and spa flex so that I can slide the sump out later to remove the protein skimmer and any other periodic maintenance.

When I got around to the final portion, assembling the standpipes, I realized that there was not enough room for 3x 1.5" dursos. For now, I am going to use a 1.5 to 1.25 reducer and make 3x of the 1.25 dursos. If I need to later I can switch to Stockman's, etc. or a Bean Animal drain.

Finally, I painted the other stands and frame around the sink with some leftover tan paint.

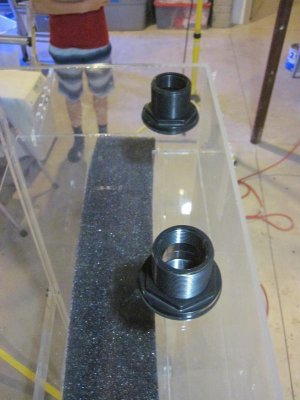

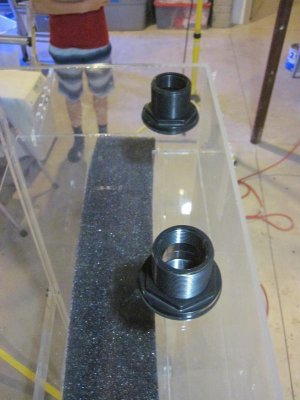

I have a few missing plumbing parts for the return side I need to order this week and then I have to drill the sump for the bulkheads. I've drilled four or five tanks before, but I'm still nervous about messing up my brand new sump.

Pics

Plumbing of the overflow side completed

I used the unions and spa flex so that I can slide the sump out later to remove the protein skimmer and any other periodic maintenance.

When I got around to the final portion, assembling the standpipes, I realized that there was not enough room for 3x 1.5" dursos. For now, I am going to use a 1.5 to 1.25 reducer and make 3x of the 1.25 dursos. If I need to later I can switch to Stockman's, etc. or a Bean Animal drain.

Finally, I painted the other stands and frame around the sink with some leftover tan paint.

I have a few missing plumbing parts for the return side I need to order this week and then I have to drill the sump for the bulkheads. I've drilled four or five tanks before, but I'm still nervous about messing up my brand new sump.

Raoul5Duke

Active member

More Updates

More Updates

Its been a few weeks, but I have gotten some things accomplished. I installed some bookshelf lights from Ikea under the stand so I can see when I work. Additionally, I drilled the sump for my two 1.5" bulkheads so I can plumb the two Reeflo Darts. Finally, I added a 3rd support line and reinforced the light rack with some additional pieces from 80/20. Next up are pics of the finished plumbing and water test.

More Updates

Its been a few weeks, but I have gotten some things accomplished. I installed some bookshelf lights from Ikea under the stand so I can see when I work. Additionally, I drilled the sump for my two 1.5" bulkheads so I can plumb the two Reeflo Darts. Finally, I added a 3rd support line and reinforced the light rack with some additional pieces from 80/20. Next up are pics of the finished plumbing and water test.

Raoul5Duke

Active member

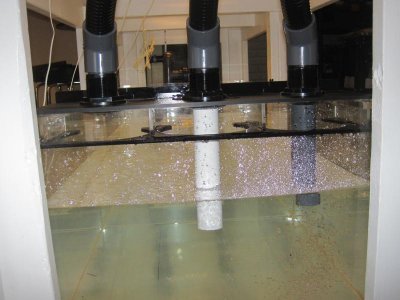

Plumbing and Water Test

Plumbing and Water Test

I finished plumbing the return side. I plumbed the two Reeflos so that they can be taken offline easily and one can be diverted while the other is shut off. The return line is very basic, just a straight shot up the wall that wraps around to the back corner of the tank. I don't think I am going to do anything else with it at this time.

Here are some pics from the water test. I was pretty nervous as it filled up given we built the stand on our own, but everything held up fine. Due to my previous problems of not being able to fit 1.5" dursos into the overflow box I went with 1.25" and converted to a BeanAnimal overflow. I am really happy with the results. I was able to crank the Reeflo up to 3/4 open and it handled the flow without any issues. I have some things to do to fine tune the system but I am very happy with this overflow so far. There are a couple of small leaks that need to be fixed and I am starting to reconsider running my manifold off a separate dedicated pump vs. the Reeflos but I am not sure yet. I want to calculate the approx. flow of everything to see what the best choice is.

Plumbing and Water Test

I finished plumbing the return side. I plumbed the two Reeflos so that they can be taken offline easily and one can be diverted while the other is shut off. The return line is very basic, just a straight shot up the wall that wraps around to the back corner of the tank. I don't think I am going to do anything else with it at this time.

Here are some pics from the water test. I was pretty nervous as it filled up given we built the stand on our own, but everything held up fine. Due to my previous problems of not being able to fit 1.5" dursos into the overflow box I went with 1.25" and converted to a BeanAnimal overflow. I am really happy with the results. I was able to crank the Reeflo up to 3/4 open and it handled the flow without any issues. I have some things to do to fine tune the system but I am very happy with this overflow so far. There are a couple of small leaks that need to be fixed and I am starting to reconsider running my manifold off a separate dedicated pump vs. the Reeflos but I am not sure yet. I want to calculate the approx. flow of everything to see what the best choice is.

Raoul5Duke

Active member

Looks great, your making serious progress now. Should be able to move some serious water around with the mp60's.

Thanks. Once I get a few small leaks repaired I want to test the MP60s out. I'm guessing at 3/4 open valve on the Reeflo I was pushing close to 2,700-3,000 GPH and I think the overflow could handle more. This is obviously way more flow then I likely want moving through my sump. I think I will target closer to 5x turnover which is ~ 1,800 and then I can run the manifold off of just one pump and reserve the other for backup or alternate monthly.

I have some videos, but need to figure out how to upload them.

Similar threads

- Replies

- 1

- Views

- 223