You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Acrylic fabrication questions? I can help!

- Thread starter JohnL

- Start date

Plastic extrusion pen question

Plastic extrusion pen question

I have a plastic writing pen and I'm wondering if it's safe to use it to print out a little cave kind of structure to put into my fry float tank. There's only one poor lonely ghost shrimp fry that just got caught up in the net when they scooped up the adults we were purchasing. One female was pregnant and we had high hopes that the little guy wouldn't be alone long but sadly big momma didn't make it through the stress of the transition.:thumbdown So the little fry "Fragle Rock" has been by himself in a pretty empty fry float tank that just has him and a live plant in it. I want to know if it's safe to use my Simo Mini to draw out an abs rock and also if the color of the abs matters, as well as anything else I can do to make his/her stay better and healthier and also encourage more growth so he can join the rest of the tank outside of his isolation safely. I'd be devastated now if he got ate or something the minute we let him into the big (relative term here lol) tank amongst all our other residents. We don't want to get any more ghost shrimp fry unless one of the females gets pregnant naturally, and tho we wouldn't mind some RCS fry or others we only have two females atm and the stores never seem to have those in stock at all let alone accidentally like the way Fragle came to us. So thoughts on the abs safety and any other tips to keep a happy healthy and growing Fry?

Plastic extrusion pen question

I have a plastic writing pen and I'm wondering if it's safe to use it to print out a little cave kind of structure to put into my fry float tank. There's only one poor lonely ghost shrimp fry that just got caught up in the net when they scooped up the adults we were purchasing. One female was pregnant and we had high hopes that the little guy wouldn't be alone long but sadly big momma didn't make it through the stress of the transition.:thumbdown So the little fry "Fragle Rock" has been by himself in a pretty empty fry float tank that just has him and a live plant in it. I want to know if it's safe to use my Simo Mini to draw out an abs rock and also if the color of the abs matters, as well as anything else I can do to make his/her stay better and healthier and also encourage more growth so he can join the rest of the tank outside of his isolation safely. I'd be devastated now if he got ate or something the minute we let him into the big (relative term here lol) tank amongst all our other residents. We don't want to get any more ghost shrimp fry unless one of the females gets pregnant naturally, and tho we wouldn't mind some RCS fry or others we only have two females atm and the stores never seem to have those in stock at all let alone accidentally like the way Fragle came to us. So thoughts on the abs safety and any other tips to keep a happy healthy and growing Fry?

Floyd R Turbo

Either busy or sleeping

not to bad of a bow

The bow you care about is not really top to bottom, it's side-to-side. Spin the level horizontal and hold it so it is touching in the middle and measure the gap on each end - that's your bow

Floyd R Turbo

Either busy or sleeping

So is there some place that shows the pin method? Are you supposed to put pins in the bottom and sides? Don't the pieces shift when you pull the pins out?

http://www.reefcentral.com/forums/showthread.php?t=169326

http://www.reefcentral.com/forums/showthread.php?t=390652

Floyd R Turbo

Either busy or sleeping

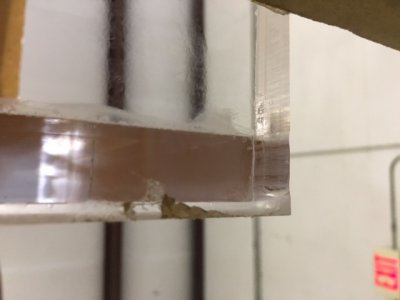

ugh...I'm amazed you got that to be free of bubbles with that tie in there!! Must have been a pretty thin one. For future reference, you only need to stick the metal pin into the joint far enough to cause a separation - about 2-4 millimeters is all. Putting the pin all the way through the joint causes it to form a dam and block the solvent from flowing past the pin, so you will have a higher chance of bubbles forming throughout the joint, because you have to keep re-starting the solvent flow.

For this one, it would seem to me personally that the weight of everything might eventually cause a crack to form in the vertical panel over time, or maybe the horizontal panel, or eventual separation starting with the area around that pin. I wouldn't trust it myself.

Maybe James has further advice, I'm always on the safe side. A foreign object in the joint throws in a huge roll-of-the-dice factor....

For this one, it would seem to me personally that the weight of everything might eventually cause a crack to form in the vertical panel over time, or maybe the horizontal panel, or eventual separation starting with the area around that pin. I wouldn't trust it myself.

Maybe James has further advice, I'm always on the safe side. A foreign object in the joint throws in a huge roll-of-the-dice factor....

karimwassef

Active member

Floyd - I'm building with 3/4" acrylic, but the structure will be subject to stresses both internal and external. It's 2' wide x 4' x 4' high and with the top made water tight with an opening panel, a seal and plastic screws... and airtight.

It'll have holes connected to the tank and I'm using a vacuum to suck water up into it... that's the negative pressure than would make it implode. and then letting it go full of water to the top, that's the positive pressure that would make it explode. This happens every minute... 45 seconds to fill (negative), 15 seconds to purge (positive).

How would you build it?

Oh, and there are 4 of them: 2 side by side and then front to back.

Some will be negative while others are positive and vice versa... but I was going to build them as one container with 4 completely isolated chambers.

<a href="http://s1062.photobucket.com/user/karimwassef/media/Designs/1_zpsyeew4yzx.jpg.html" target="_blank"><img src="http://i1062.photobucket.com/albums/t496/karimwassef/Designs/1_zpsyeew4yzx.jpg" border="0" alt=" photo 1_zpsyeew4yzx.jpg"/></a>

<a href="http://s1062.photobucket.com/user/karimwassef/media/Designs/2_zpsbftliddf.jpg.html" target="_blank"><img src="http://i1062.photobucket.com/albums/t496/karimwassef/Designs/2_zpsbftliddf.jpg" border="0" alt=" photo 2_zpsbftliddf.jpg"/></a>

Also, while I need to see how high the water is inside somewhere, the whole structure doesn't need to be clear. it's pretty if it is, but I was thinking of wrapping it all in a two-sheets 3/4" plywood "glove" to keep it all tightly held together as it gets worked. Maybe 2x4s in a frame at the top, middle and bottom would be just as good.

pin method with thick acrylic solvent?

It'll have holes connected to the tank and I'm using a vacuum to suck water up into it... that's the negative pressure than would make it implode. and then letting it go full of water to the top, that's the positive pressure that would make it explode. This happens every minute... 45 seconds to fill (negative), 15 seconds to purge (positive).

How would you build it?

Oh, and there are 4 of them: 2 side by side and then front to back.

Some will be negative while others are positive and vice versa... but I was going to build them as one container with 4 completely isolated chambers.

<a href="http://s1062.photobucket.com/user/karimwassef/media/Designs/1_zpsyeew4yzx.jpg.html" target="_blank"><img src="http://i1062.photobucket.com/albums/t496/karimwassef/Designs/1_zpsyeew4yzx.jpg" border="0" alt=" photo 1_zpsyeew4yzx.jpg"/></a>

<a href="http://s1062.photobucket.com/user/karimwassef/media/Designs/2_zpsbftliddf.jpg.html" target="_blank"><img src="http://i1062.photobucket.com/albums/t496/karimwassef/Designs/2_zpsbftliddf.jpg" border="0" alt=" photo 2_zpsbftliddf.jpg"/></a>

Also, while I need to see how high the water is inside somewhere, the whole structure doesn't need to be clear. it's pretty if it is, but I was thinking of wrapping it all in a two-sheets 3/4" plywood "glove" to keep it all tightly held together as it gets worked. Maybe 2x4s in a frame at the top, middle and bottom would be just as good.

pin method with thick acrylic solvent?

That was the fourth joint on a 96" x 30" x 30", so there was a fair amount of weight on it.

Another thought is to cut/drill it out and fill with 40, but I don't know if that would make it better or worse. Any crafty ideas or am I changing dimensions by a couple inches?

appreciated

Another thought is to cut/drill it out and fill with 40, but I don't know if that would make it better or worse. Any crafty ideas or am I changing dimensions by a couple inches?

appreciated

Floyd R Turbo

Either busy or sleeping

That was the fourth joint on a 96" x 30" x 30", so there was a fair amount of weight on it.

Another thought is to cut/drill it out and fill with 40, but I don't know if that would make it better or worse. Any crafty ideas or am I changing dimensions by a couple inches?

appreciated

@nyxmaven, my thought would be drill & fill, that would at least eliminate the potential pressure point. It doesn't have to be a large diameter bit either, just big enough to be able to clean it out and get the 40 in there with a syringe, dam it up on both sides, sand & polish.

But, I would wait for James to chime in. I know he hates tank repair questions, but this is not an old busted tank, so this one should be more straight forward....

Floyd R Turbo

Either busy or sleeping

Floyd - I'm building with 3/4" acrylic, but the structure will be subject to stresses both internal and external. It's 2' wide x 4' x 4' high and with the top made water tight with an opening panel, a seal and plastic screws... and airtight.

It'll have holes connected to the tank and I'm using a vacuum to suck water up into it... that's the negative pressure than would make it implode. and then letting it go full of water to the top, that's the positive pressure that would make it explode. This happens every minute... 45 seconds to fill (negative), 15 seconds to purge (positive).

How would you build it?

Oh, and there are 4 of them: 2 side by side and then front to back.

Some will be negative while others are positive and vice versa... but I was going to build them as one container with 4 completely isolated chambers.

Also, while I need to see how high the water is inside somewhere, the whole structure doesn't need to be clear. it's pretty if it is, but I was thinking of wrapping it all in a two-sheets 3/4" plywood "glove" to keep it all tightly held together as it gets worked. Maybe 2x4s in a frame at the top, middle and bottom would be just as good.

pin method with thick acrylic solvent?

So first of all, you're some kind of insane scientist, aren't you?

But on the level, I'm not sure what effect you're going to see from the positive/negative pressure thing. That's going to be constantly changing the forces on the seams. Now if that was just a straight "fill" and "dump", that's one thing. Using a vaccuum method takes it to a different level, so I really don't know for sure how to answer this one

karimwassef

Active member

Ok. Assume it's a violent surge- what would you do?

I is a enginir

I is a enginir

Floyd R Turbo

Either busy or sleeping

Does it have to be visible? i.e. can you consider another material, like a premanufactured poly tank, etc?

karimwassef

Active member

no. I don't need to see in it except maybe for a sliver to tell the water level.

My alternative is plywood with epoxy.

pre-fab tanks of this size are more expensive than acrylic tanks.

My alternative is plywood with epoxy.

pre-fab tanks of this size are more expensive than acrylic tanks.

Floyd R Turbo

Either busy or sleeping

$300 for a 250 gallon vertical Norwesco poly tank?

https://www.google.com/search?q=norwesco+41854&ie=utf-8&oe=utf-8#q=norwesco+41854&tbm=shop

I would challenge you to find a $300 acrylic tank with those dims for $300....

https://www.google.com/search?q=norwesco+41854&ie=utf-8&oe=utf-8#q=norwesco+41854&tbm=shop

I would challenge you to find a $300 acrylic tank with those dims for $300....

Floyd, in general what do you think about running some weldon 40 for fillets? All of my seams are good but I'm just paranoid about coming home to find 180g of water on my floor.

Also I'm getting close to my first test fill and I was planning on leaving in the garage full of water for about a month to make sure it holds up. If it makes it that month are the odds pretty good that I won't have any issues?

Also I'm getting close to my first test fill and I was planning on leaving in the garage full of water for about a month to make sure it holds up. If it makes it that month are the odds pretty good that I won't have any issues?

Floyd R Turbo

Either busy or sleeping

Personally, I would drill it out and fill it in. It's a much better long term solution if you ask me, you don't know what kind of reactions are going to take place over time with that metal piece in there. Then do WO 40 in the hole and a fillet at the same time.

You should be able to drill a hole that is right about the size of a #16 applicator needle or smaller and push the 40 through the hole, dam up the other side after it's full (just use blue tape I'm thinking) and then pour the fillet across the joint right after that and let it all cure together.

Remember to very slightly rough up the area for the fillet pour (150 grit sandpaper, just a few light passes)

You should be able to drill a hole that is right about the size of a #16 applicator needle or smaller and push the 40 through the hole, dam up the other side after it's full (just use blue tape I'm thinking) and then pour the fillet across the joint right after that and let it all cure together.

Remember to very slightly rough up the area for the fillet pour (150 grit sandpaper, just a few light passes)

karimwassef

Active member

$300 for a 250 gallon vertical Norwesco poly tank?

https://www.google.com/search?q=norwesco+41854&ie=utf-8&oe=utf-8#q=norwesco+41854&tbm=shop

I would challenge you to find a $300 acrylic tank with those dims for $300....

I did check those out but I need a flat surface to mount 12 x 3" uniseals to.

Need 24" x 48" x 60" high now. I did find the doorway tanks but the curvature on the bottom and the big holes in the middle eat up my access area.

Unless I find a reasonable solution, I'm probably going plywood

karimwassef

Active member

Maybe go hybrid?

https://www.ntotank.com/325gallon-acerotomold-white-opentop-containment-tank-x8666939

I could use these tanks and create a rectangular interface box underneath: 3' x 4' x 1' high each. These would use three large 6" uniseals to connect up to the containers above, then 12 x 3" uniseals to the side.

More connections means more potential fault points but that could be a cheaper alternative?

So how would I build a rock solid low cost acrylic 36" x 48" box at 12" high? It needs to be able to carry 2600 lbs of tank and water above it...

https://www.ntotank.com/325gallon-acerotomold-white-opentop-containment-tank-x8666939

I could use these tanks and create a rectangular interface box underneath: 3' x 4' x 1' high each. These would use three large 6" uniseals to connect up to the containers above, then 12 x 3" uniseals to the side.

More connections means more potential fault points but that could be a cheaper alternative?

So how would I build a rock solid low cost acrylic 36" x 48" box at 12" high? It needs to be able to carry 2600 lbs of tank and water above it...

karimwassef

Active member

For clarity... I can't use elbows.. each elbow is the equivalent of 13 ft of pipe and kills the head pressure on my surge.

Similar threads

- Replies

- 2

- Views

- 808

- Replies

- 4

- Views

- 506

- Replies

- 12

- Views

- 2K