Rovert

Premium Member

Howdy, folks. I'm the new owner of a CADE 1800S2 and would like to get some advice on what parts I'd need to redirect the return flow from the top right of the tank to be central, and front-facing.

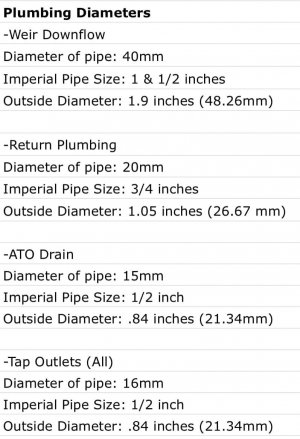

My plan was to make a 90-degree bend off the bulkhead into a straight pipe, run that pipe lengthwise against the back wall, make another 90-degree bend to face forward, and terminate to either a LocLine nozzle or just cap the end and drill some holes to make a basic spray bar. My biggest confusion is at the bulkhead, I'm not sure which bits-and-bobs I need to get that to happen.

I'm looking at these plumbing parts at BRS here, since they're all black or dark gray and would blend in with the back glass. Just don't know what I'd need to 'convert' the CADE bulkead/nozzle configuration to what I'm looking for.

www.bulkreefsupply.com

www.bulkreefsupply.com

Thanks in advance!

My plan was to make a 90-degree bend off the bulkhead into a straight pipe, run that pipe lengthwise against the back wall, make another 90-degree bend to face forward, and terminate to either a LocLine nozzle or just cap the end and drill some holes to make a basic spray bar. My biggest confusion is at the bulkhead, I'm not sure which bits-and-bobs I need to get that to happen.

I'm looking at these plumbing parts at BRS here, since they're all black or dark gray and would blend in with the back glass. Just don't know what I'd need to 'convert' the CADE bulkead/nozzle configuration to what I'm looking for.

Schedule 80 Fittings

Bulk Reef Supply - Saltwater Aquarium Supplies for Reef Tanks

Thanks in advance!