Southsid_reefer

New member

Well as some of you may know, I have started my own business and things are really starting to take off. So we need to setup more systems to supply more stock.

I started my build 2 weeks ago on 3 tanks made of 3/4 PVC foam board that I purchased from Faulkner Plastic. I purchased 3-8x4 foot sheets and had them cut to to size to make Tanks that are 74x24x10. I screwed the tanks together with stainless steel screws (they don't come in contact with the water) and then sealed. Tanks were also braced on the inside with 1in pieces to make an extra seal. We tested them today and all three passed, no leaks

We also build all 3 stands out of 2x4 and painted them with satin black waterproofing stain. They look great. Tomorrow we will continue to run all the electrical and move the 2-60 gallon frag tanks to the other side of the garage( that's going to be fun)

.

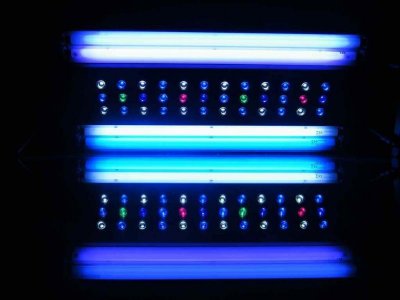

Haven't made up my mind on lighting but I would like to setup up LEDs on all tanks but that would be pricey, so for now I may just go with a some MH on light movers on each tank.

Tanks will be setup with a auto water change system.

more updates to come.....

I started my build 2 weeks ago on 3 tanks made of 3/4 PVC foam board that I purchased from Faulkner Plastic. I purchased 3-8x4 foot sheets and had them cut to to size to make Tanks that are 74x24x10. I screwed the tanks together with stainless steel screws (they don't come in contact with the water) and then sealed. Tanks were also braced on the inside with 1in pieces to make an extra seal. We tested them today and all three passed, no leaks

We also build all 3 stands out of 2x4 and painted them with satin black waterproofing stain. They look great. Tomorrow we will continue to run all the electrical and move the 2-60 gallon frag tanks to the other side of the garage( that's going to be fun)

.

Haven't made up my mind on lighting but I would like to setup up LEDs on all tanks but that would be pricey, so for now I may just go with a some MH on light movers on each tank.

Tanks will be setup with a auto water change system.

more updates to come.....