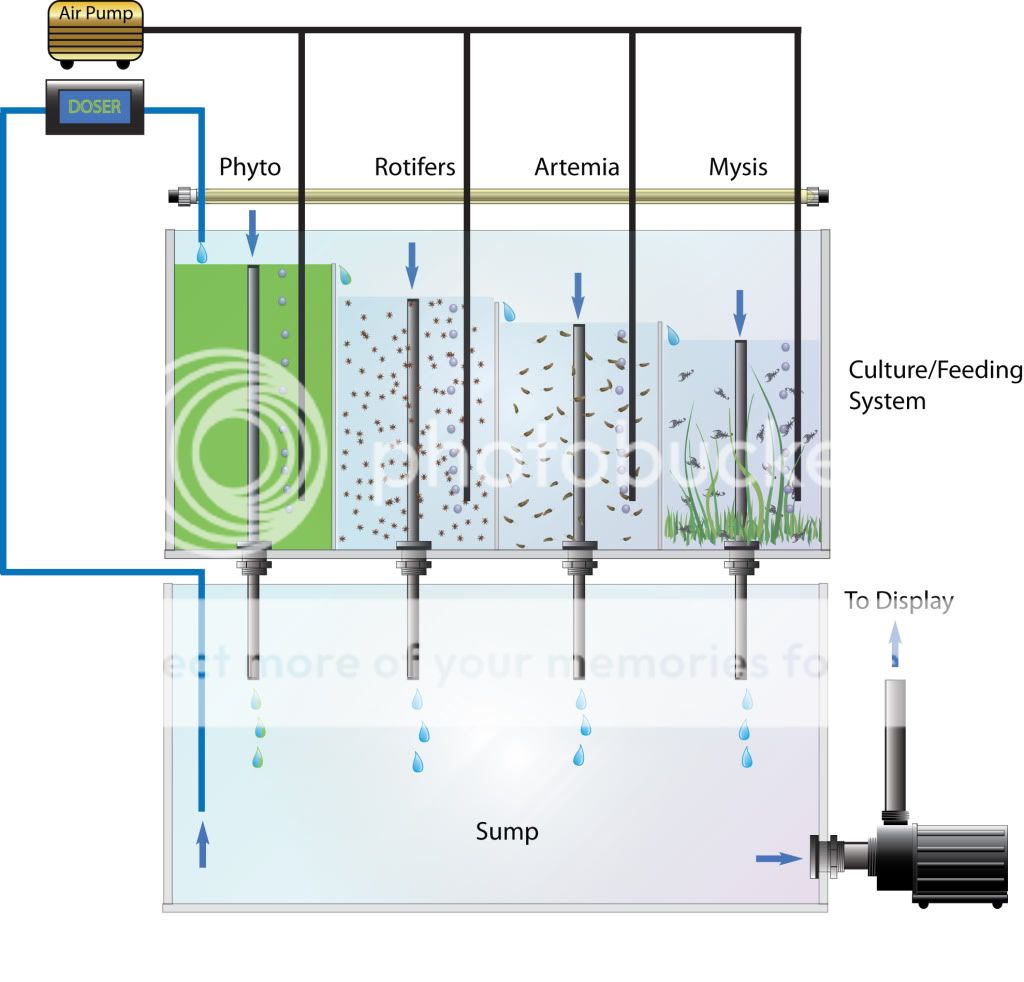

The next project for Peter's tank will be a live food culturing system. I'm working on a design that will allow passive automated feeding. Basically, a dosing pump periodically delivers fresh system water to a series of independent live food tanks, allowing them to overflow down through a standpipe into the sump below, and over an internal dam feeding the next level of the food pyramid.

At the bottom of the food chain we have Phytoplankton, then rotifers (zooplankton), then Brine Shrimp/Artemia Nauplii (zooplankton), and finally the larger Mysid Shrimp (zooplankton). Each live food item grows at a different rate with the bottom end (phytoplankton) growing at the fastest rate followed up the food chain to the slowest (mysis shrimp).

It is important to segregate each item as contamination can wipe out the food source. For this reason, the airlift is placed at the end that is down the food chain and the dam is high enough to discourage cross-contamination.

An air line will keep water moving and protect the live food from being damaged in pumps or filters. A turkey baster will be used to collect food as well for target feeding. The dosing pump will be adjusted to keep the cultures from overpopulating and crashing and to control water quality. The dosing pump will come on periodically for a few minutes, perhaps for one minute once an hour???

Brine shrimp are photosensitive and attracted to light, so they will be concentrated at the surface where it is easy to overflow them to the mysis or standpipe to the sump. The light will also keep the tanks warm for faster growth. I will have to adjust the size of each tank to support the biomass and feeding requirements.

I don't expect this system to be self sustaining. It will periodically crash and will require replenishing. The idea is to have a steady supply of live food for the display tank, via the sump to feed bacteria, invertebrates and fish. Brine shrimp will be hatched in a separate vessel to keep the floating hatched cysts from overflowing into the sump and mysis tank.

Here is a drawing of what I have in mind. Let me know if you have any ideas or spot any design flaws.