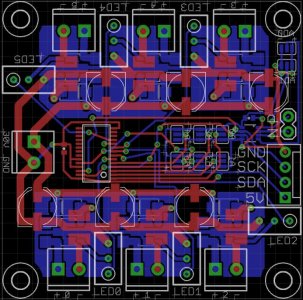

I'm working on an 6 driver PT4115 based board with a PCA9685 to do the dimming and TMP421 for temp sensors. Since I was running 2 I2C slave devices on one board and then going to a remote master I wanted to read up on the I2C stuff a bit more. I found several forum posts and these tutorials that stated that 1m was the limit for I2C.

http://tronixstuff.wordpress.com/2010/10/20/tutorial-arduino-and-the-i2c-bus/

http://tronixstuff.wordpress.com/2010/10/29/tutorial-arduino-and-the-i2c-bus-part-two/

A lot of those tutorials aren't real world so I trust your real world experience with the distance. I'm short on board space anyhow so I'll leave out the I2C extender and if I end up having issues I can always add on external I2C extender boards.

http://tronixstuff.wordpress.com/2010/10/20/tutorial-arduino-and-the-i2c-bus/

http://tronixstuff.wordpress.com/2010/10/29/tutorial-arduino-and-the-i2c-bus-part-two/

A lot of those tutorials aren't real world so I trust your real world experience with the distance. I'm short on board space anyhow so I'll leave out the I2C extender and if I end up having issues I can always add on external I2C extender boards.