You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY LEDs - The write-up

- Thread starter JohnL

- Start date

- Status

- Not open for further replies.

DennisJensen

New member

If you plan to run the Buck's at a usable current, those Resistors will get HOT, 1ohm and 1A current equals 1W, 4 times the rated effect.<a href=showthread.php?s=&postid=15699933#post15699933 target=_blank>Originally posted</a> by jimnrose

I received a large quantity of 1 ohm 1% 1/4w resistors and could share them with anyone who is having trouble getting these 1% resistors. I'll use them in series with the Buckpuck loads to measure the current draw. I couldn't find them except from a Thialand supplier & it took three weeks in transit. Jim

750mA will burn off 0.56W. i would recommend a 0.1ohm for current measurement.

D.

stugray

Premium Member

jimnrose,

"I also have the resistors on each of 12 loads & wire the resistors only during the set-up phase. "

Are you just using the resistors as a shunt ( current measuring device )?

Why dont you just use the DMM you are using to check the voltage, in current mode in series?

Thats how I set the meanwell ELN-60-48 to 700mA.

Stu

"I also have the resistors on each of 12 loads & wire the resistors only during the set-up phase. "

Are you just using the resistors as a shunt ( current measuring device )?

Why dont you just use the DMM you are using to check the voltage, in current mode in series?

Thats how I set the meanwell ELN-60-48 to 700mA.

Stu

Stugray,

My DMM has a 10amp range and as you said it has to connected in series to the load. I found it easier to leave the shunt resistors in place with a bypass wire. That way I can just read across the shunt resistor (opening the bypass lead) to read the voltage. Also the resistors are 1% values while the DMM isn't as accurate or that's what I'm guessing. Take care, Jim

My DMM has a 10amp range and as you said it has to connected in series to the load. I found it easier to leave the shunt resistors in place with a bypass wire. That way I can just read across the shunt resistor (opening the bypass lead) to read the voltage. Also the resistors are 1% values while the DMM isn't as accurate or that's what I'm guessing. Take care, Jim

AndyReef

New member

Has anyone found a simple way to mount cooling fans so as not to transfer the vibrations into the heatsink?

I can hear my fans on the third floor of my house while the aquarium is on the first floor. If I lift them up from the heatsink they are virtually silent. They are working great though. The max temp with the fans off was nearly 150 F and with the fans running they barely go above 100.

I can hear my fans on the third floor of my house while the aquarium is on the first floor. If I lift them up from the heatsink they are virtually silent. They are working great though. The max temp with the fans off was nearly 150 F and with the fans running they barely go above 100.

Reef_Matrix29

Water Lover

Rubber grommet feet could help with the vibration Andy.

Radioheadx14

Active member

I'm planning using DIY LEDs for my 37g seahorse tank (low power comsumption, low heat transfer which is a must in SH tanks)

I've read the beginning of this long thread and a few pages as of lately, and it seems things have changed through out the posts, so i have a few questions:

1.) If I wanted to light a 24"x18"x20" tank, how many lights should I use if i want to grow macro algae like calerpa and maybe some gorgonians, zoas, ricordea/shrooms and leathers? I was thinking maybe 12-18.

In the beginning everyone was using a power supply and buckpucks... then I am reading about these Mean Well LPC-35-700W constant current driver... whats the difference? does one Mean Well replace the buckpuck and power supply?

Also, what is the difference between Cree XR-E Q5 Emitter (http://www.dealextreme.com/details.dx/sku.2394) and the CREE XR-E Q4 Cool White 3W LED? the former is a lot cheaper.

Has anyone tried lapping the heatsinks? I know a lot of CPU overclockers say lapping the heat spreader and cpu to where its a mirror finish creates better heat transfer than using a thermal compounds like arctic silver.

I've read the beginning of this long thread and a few pages as of lately, and it seems things have changed through out the posts, so i have a few questions:

1.) If I wanted to light a 24"x18"x20" tank, how many lights should I use if i want to grow macro algae like calerpa and maybe some gorgonians, zoas, ricordea/shrooms and leathers? I was thinking maybe 12-18.

In the beginning everyone was using a power supply and buckpucks... then I am reading about these Mean Well LPC-35-700W constant current driver... whats the difference? does one Mean Well replace the buckpuck and power supply?

Also, what is the difference between Cree XR-E Q5 Emitter (http://www.dealextreme.com/details.dx/sku.2394) and the CREE XR-E Q4 Cool White 3W LED? the former is a lot cheaper.

Has anyone tried lapping the heatsinks? I know a lot of CPU overclockers say lapping the heat spreader and cpu to where its a mirror finish creates better heat transfer than using a thermal compounds like arctic silver.

kcress

New member

Re: fans

Re: fans

You have to be a bit careful there as the slowest they will spin is slower than they can start at. So if you adjust them down really slow and the power cycles they may stop and never start again. So I just mention the caveat that you check that when speed adjusting a fan(s).

Re: fans

<a href=showthread.php?s=&postid=15715701#post15715701 target=_blank>Originally posted</a> by kecked

Turn down the speed of the fans and monitor the temp. Get the lowest temp you can for the rpm.

You have to be a bit careful there as the slowest they will spin is slower than they can start at. So if you adjust them down really slow and the power cycles they may stop and never start again. So I just mention the caveat that you check that when speed adjusting a fan(s).

AndyReef

New member

MeanWell is a powersupply that has constant current DC output. It will drive 12 or 13 cree XREs at 1000 mA. As far as the q5 and q4 go, they are very similar in light output, the q5 is slightly more efficient, but the cost difference is pretty significant and the difference in output is not.

Michael_84

New member

<a href=showthread.php?s=&postid=15446257#post15446257 target=_blank>Originally posted</a> by sammy113

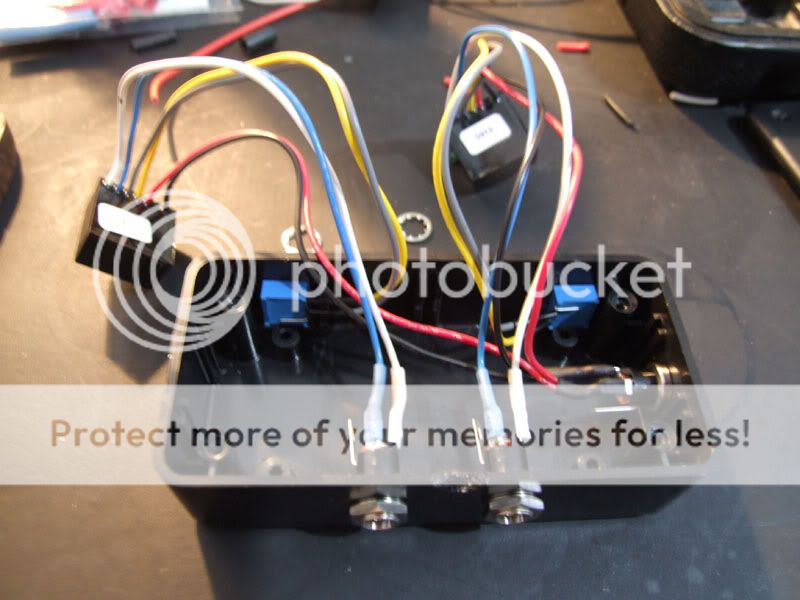

I found this plugs at Radio Shack. I used them to disconnect and connect the power supply from the drivers and the drivers from the lamp.

Guitar connectors...? I know from experience that these will corrode badly if they are near salt. and they are only meant for very low power levels. BE CAREFUL!!@!

sammy113

New member

This are not guitar connectors. Guitar connectors are 1/4" Jack and are not meant for high voltages like this application. This are Power Connectors and are way smaller than guitar's. Its just like the ones that comes with external hard drives, routers, modems and all those 12v stuff

Reef_Matrix29

Water Lover

I would go with 24 LED's total and you decide how "blue" you want you water to be with the ration from 1:1 to 2:1 white to blue respectively. Meanwell's would be my suggestion and definitely Q5's and perhaps turn down the current to 700mA if they are too bright, that's what I did over my 75G.

Radioheadx14

Active member

What size heat sink should i get? I was thinking of getting a 9" Large width HS and cutting it into 2 9" heat sinks, then putting 12 per heat sink... that way I could mount on on the openning top of my canopy and one one the back part of my canopy (my canopy is basically cut down the middle, the front half hinges up and the back half doesnt move.)

So i would need 12 whites, 12 blues, 2 meanwell's and a heat sink, CPU thermal grease and thats it? (besides the extra things like wires, screws etc)

So i would need 12 whites, 12 blues, 2 meanwell's and a heat sink, CPU thermal grease and thats it? (besides the extra things like wires, screws etc)

Reef_Matrix29

Water Lover

Hmmmmm....i wouldn't cut the heatsink personally, just get two the size that you want them to be or the close length to that. When I do a new array in a few months or so depending on funds, I will get one 36" heatsink to span a 120 gallon tank. Even if I have a void in the middle, it will still absorb heat away from the LED's. Just my suggestion.

If this is going on a 24" tank, that should be a good amount of light for the space. I used Arctic alumina, but thermal grease could be just as good. You will also need a volt meter to test current and such, my meanwells were putting out 1500mA out the box and I needed to turn them down...I believe they fried 6 LED's I had hooked up while I was diagnosing a soldering problem.

You will need fans, timers and power strips too...but other than that it seems that you have everything you need. Someone jump in here if I missed anything.

If this is going on a 24" tank, that should be a good amount of light for the space. I used Arctic alumina, but thermal grease could be just as good. You will also need a volt meter to test current and such, my meanwells were putting out 1500mA out the box and I needed to turn them down...I believe they fried 6 LED's I had hooked up while I was diagnosing a soldering problem.

You will need fans, timers and power strips too...but other than that it seems that you have everything you need. Someone jump in here if I missed anything.

Radioheadx14

Active member

Would these blue CREE be the same as the more expensive ones on ledsupply.com?

http://www.dealextreme.com/details.dx/sku.1775

They are waaaay cheaper. they are on backorder but i am in no hurry.

Also, I was thinking of getting an 11" x 7.5" heat sink and make a 6x4 led array with 2" spacing. would that give me good coverage over an area of 24X18 if i dont use lenses?

http://www.dealextreme.com/details.dx/sku.1775

They are waaaay cheaper. they are on backorder but i am in no hurry.

Also, I was thinking of getting an 11" x 7.5" heat sink and make a 6x4 led array with 2" spacing. would that give me good coverage over an area of 24X18 if i dont use lenses?

Reef_Matrix29

Water Lover

It's hard to say from the information given if in fact they are the EXACT same bins without that provided...so in this case I would go with certainty over cost savings.

Well, if you feel that cutting that hunk of metal will be worth it, go for it and make sure you take pics and post them. I think that more heat removal is preferred, but if you can get away with less metal and keep the dissipation, go for it!

Well, if you feel that cutting that hunk of metal will be worth it, go for it and make sure you take pics and post them. I think that more heat removal is preferred, but if you can get away with less metal and keep the dissipation, go for it!

AndyReef

New member

I don't know if this was mentioned earlier or not but I would like to say something regarding the assembly of the LEDs to the heatsink. First, I know initially it was suggested to place the LEDs onto the heatsink with the epoxy before soldering the wires on in order to simplify the assembly. I would just like to mention from my experience on this project and previous projects, that placing them on the heatsink first is not the best method. First, the heatsink really works to absorb all the heat you are trying to use to melt the solder. Second, because of that heat capacity the LEDs really get cooked for a long period of time before you can get the solder to melt. I did have a couple of them sizzle too much. Also, the solder will reharden very quickly which is very tricky to work with. It certainly can be done this way, but it heats the LEDs a little more than I am comfortable with, takes much longer to solder, and doesn't produce the most tidy results. I ended up soldering the wires on over a wood block, and then placing the strings of LEDs onto the heatsink. My solder joints were much neater and I have a lot more confidence in them. This was using a 60W Weller iron.

Other people might have more skill than me but it was just a much better approach to solder away from the heatsink.

Other people might have more skill than me but it was just a much better approach to solder away from the heatsink.

der_wille_zur_macht

Team RC

I've recently move to another state and haven't been on much (no internet at home!) but wanted to check in on this thread.

AndyReef, what size soldering iron are you using? Soldering on the heatsink will be far easier with a powerful iron, you don't want to be using the same iron you'd use for little circuitboard work. I've found that soldering off the 'sink can cause problems in itself (it's really awkward for one thing, and can cause the joints to fail) but in the end I suppose it's to each his own.

+1 to what wesley said about those mystery blue LEDs. Who knows what bin they are. And, since they're below wholesale cost for high-binned Crees, I really doubt they're a high bin. Some people in this thread have chosen to use lower bins on purpose because "it's cheaper" but you have to keep in mind that this isn't always the case. If you could get away with 30 low-binned LEDs on a tank, you might only need 15 high-binned LEDs of the same model. That's likely less initial cost, AND less ongoing cost, as your electrical consumption will be half.

AndyReef, what size soldering iron are you using? Soldering on the heatsink will be far easier with a powerful iron, you don't want to be using the same iron you'd use for little circuitboard work. I've found that soldering off the 'sink can cause problems in itself (it's really awkward for one thing, and can cause the joints to fail) but in the end I suppose it's to each his own.

+1 to what wesley said about those mystery blue LEDs. Who knows what bin they are. And, since they're below wholesale cost for high-binned Crees, I really doubt they're a high bin. Some people in this thread have chosen to use lower bins on purpose because "it's cheaper" but you have to keep in mind that this isn't always the case. If you could get away with 30 low-binned LEDs on a tank, you might only need 15 high-binned LEDs of the same model. That's likely less initial cost, AND less ongoing cost, as your electrical consumption will be half.

- Status

- Not open for further replies.

Similar threads

- Replies

- 39

- Views

- 471

- Replies

- 0

- Views

- 122