After planning for a year and working on a new set up for 6 months a friend has convinced me to write a thread. He says my time line and setup is worth sharing. Bear with me as I run through the history of my current project. So here it goes.

After being out of the hobby for 4 years and staring at my 265 in dry storage in the garage it was time to get the insanity started again. Wanting something bigger the original plan was a 400 gallon built in tank. The wife was not too excited about this idea. Somehow she convinced me that a smaller tank would be better and it would leave room for a built in bar.

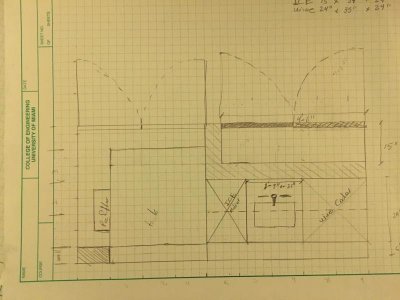

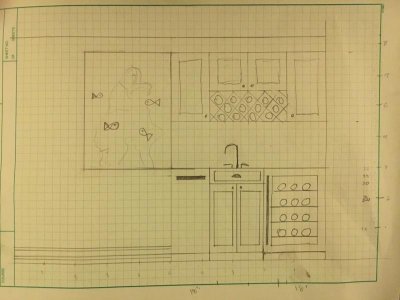

I found a tank that needed rescuing on Craigslist and that kick started the project. Here are some photos of the initial design of the bar and tank along with the tank when purchased.

After being out of the hobby for 4 years and staring at my 265 in dry storage in the garage it was time to get the insanity started again. Wanting something bigger the original plan was a 400 gallon built in tank. The wife was not too excited about this idea. Somehow she convinced me that a smaller tank would be better and it would leave room for a built in bar.

I found a tank that needed rescuing on Craigslist and that kick started the project. Here are some photos of the initial design of the bar and tank along with the tank when purchased.