As Lasse mentions, using a constant voltage power supply can be tricky & risky. Having said that, my build uses similar components with respect to chips, power supply & dimmer. I have a total of 27 ten watt multichips and am running them in parallel using two power supplies on separate timers. Each of my chips is mounted on a heatsink with fan which makes for a lot of wiring, but it's a solution that provides subsantial weight savings over mounting them on a large heatsink. I've been running my fixture since April, so about 6 months with no issues other than a fan failure which was easily repaired, no damage to LED.

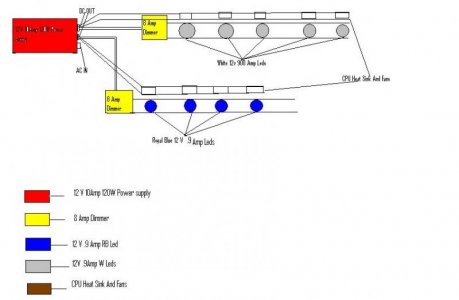

The two 12 volt power supplies are adjusted down to 10 volts output to keep them at or below the maximum forward voltage of the LEDs. The 8 amp dimmers further reduce the voltage and I run the chips at 8 volts or less to reduce the risk of burn out & subsequent increased current to remaining LEDs.

Based on my personal experience & if you keep the voltage out of the power supply at or below 10 volts, you might want to go ahead with what you have. You will need to hook up the LEDs in parallel and make sure you get appropriate heatsinks. A fuse in line with each LED would also help in the event one shorts or burns out. This will prevent the remaining LEDs from overcurrent.

If you wish to know more about my build, I have a DIY post on a canadian forum under the same user name. Below is a photo of the heatsinks I've used. A lot of soldering to hook up all 27 LEDs plus each fan, but the entire fixture weighs in at only about 12 lbs.

A couple of the photos are older & I've made a few modifications since. One of the more important & time consuming changes was to rewire all the fans. Initially I had soldered the fan leads to the LED tabs, meaning each (12 volt) fan ran at the same voltage being fed to the LED. Problem with that was, that when the lights came on in the morning at low voltage (3 to 4 volts), most of the fans would not start. This is fine since the LEDs don't produce much heat at such a low voltage/current, but not ideal for when I'm not around to kick start the fan with my finger. So I finally bit the bullet & ran another set of wires from each power supply to directly feed the fans with 10 volts. No problems with start up at that voltage and the fans actually run quieter at the higher voltage. Some of them would produce an irritating whine at slower speeds. Now I can just set the voltage to 6 volts for the whites, 8 volts for the blues & go on vacation knowing the fans will start up reliably.

Might want to order a couple of extra LEDs & heatsink/fans for spare parts. An extra power supply would not be a bad idea either.