crn005

New member

I guess it's finally time to make a build thread to kind of organize all of my information. So here it is! I got this aquarium while in college and had a porcupine puffer in it originally (yeah I know, stupid move. I had no idea what I was doing). I eventually just had a couple of clowns in it. After college, I moved to Seoul for a couple of years and left it in my mom's hands. Come to find out, she did two things. One, she started overfeeding my fish. They grew like crazy! Also, she never changed the water for two years! Anyways, the clowns roughed it out and now I have a good sized pair of mated clowns. So anyways, I decided to redo and upgrade the tank. It's up and running now with the clowns in it but it still has a decent amount of work left to be done. Money and time can be a little restricting at times though! So here it is, from where I started in February until now.

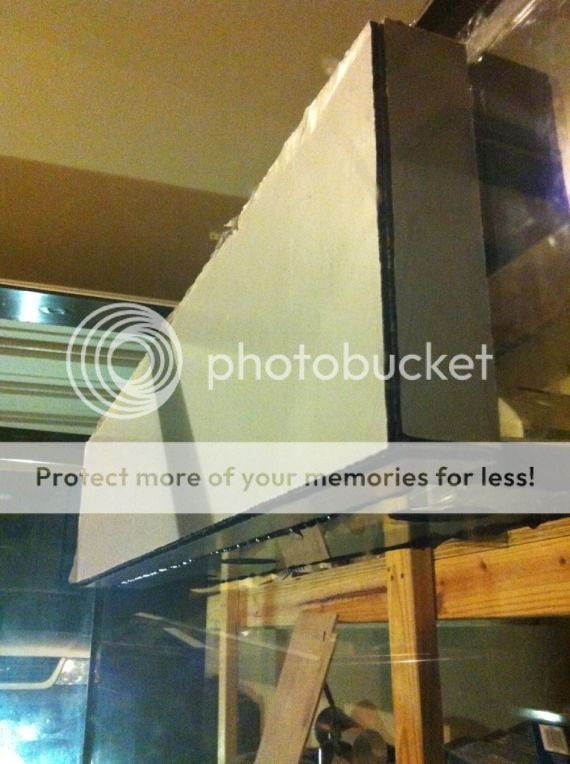

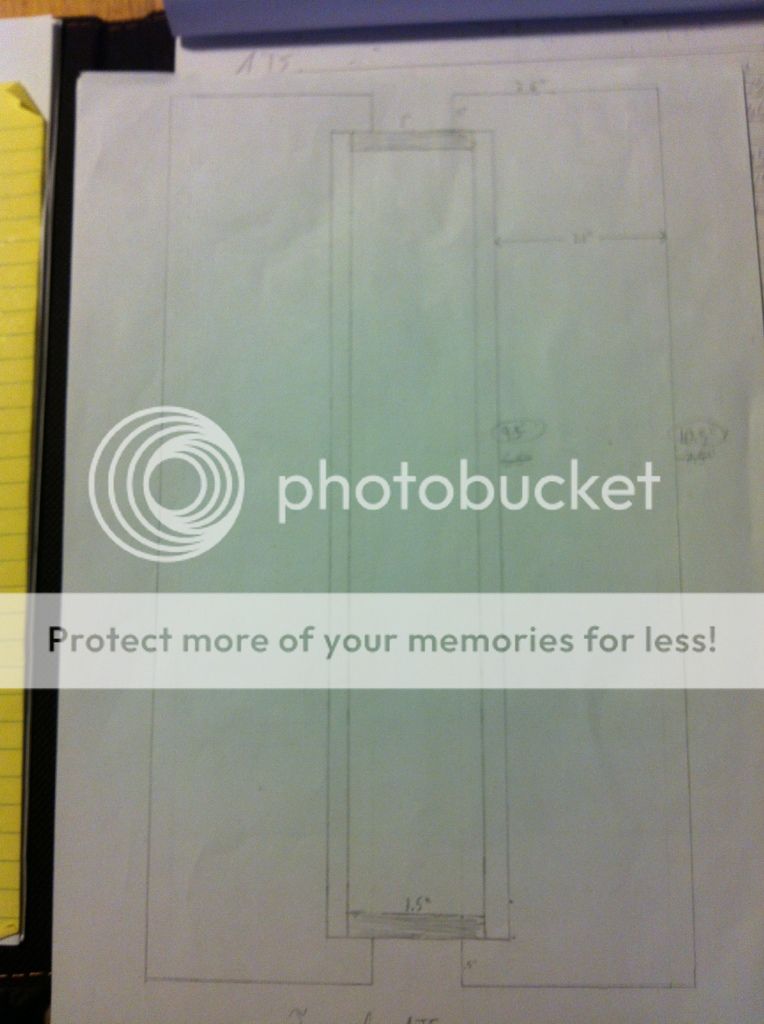

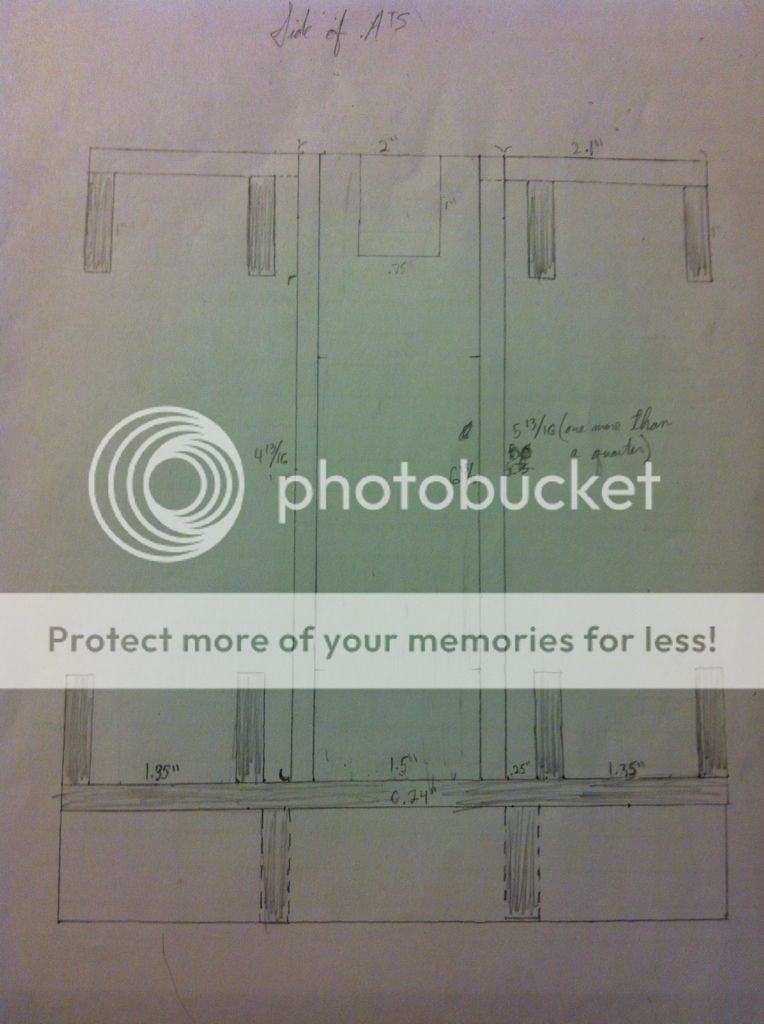

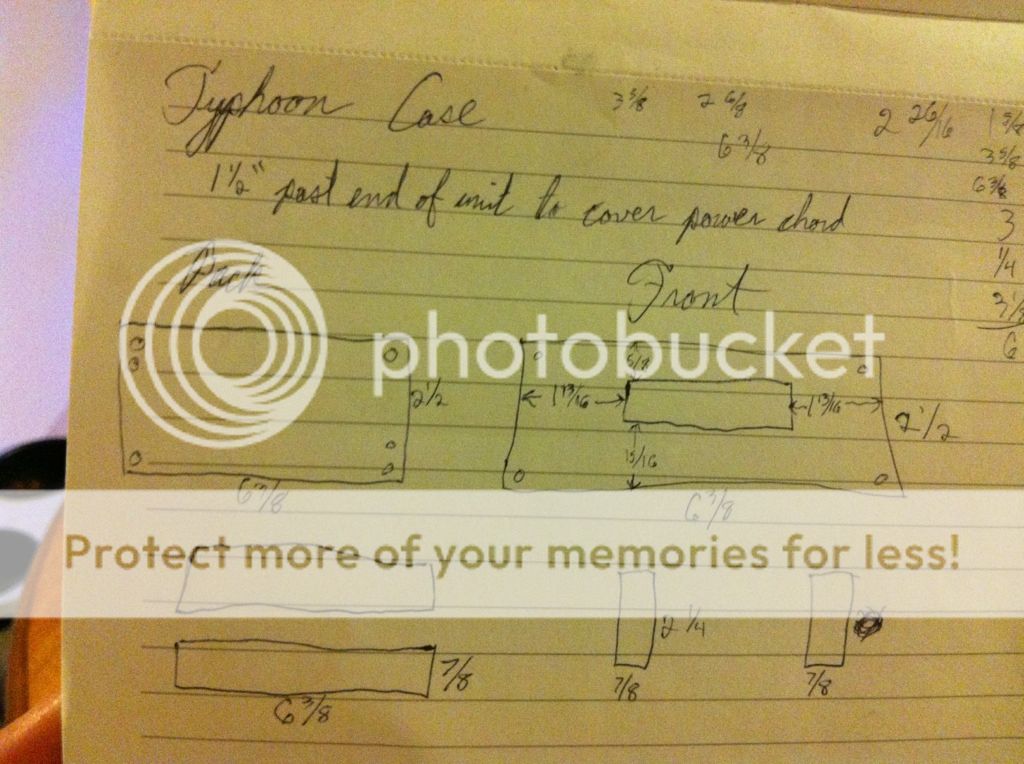

I originally decided to sand down the old stand and then stain it to match my cabinets (dark brown), but once I got to inspecting it, it needed to be redone. The stand was never sealed with anything so the creep had gotten to it. I took this opportunity to redesign it make a few upgrades. I wasn't happy about having to build a completely new stand though!

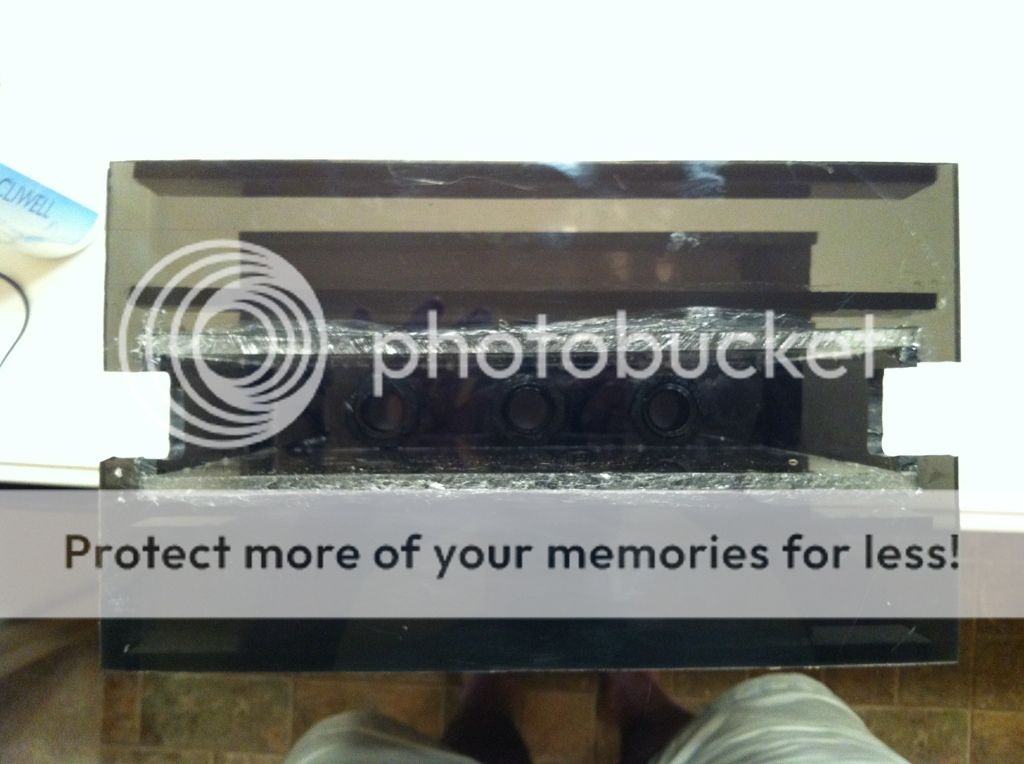

Notice how I extended the sides back and up to conceal my overflow and other equipment.

The top part is removable so I can look down into my external overflow box if I need to.

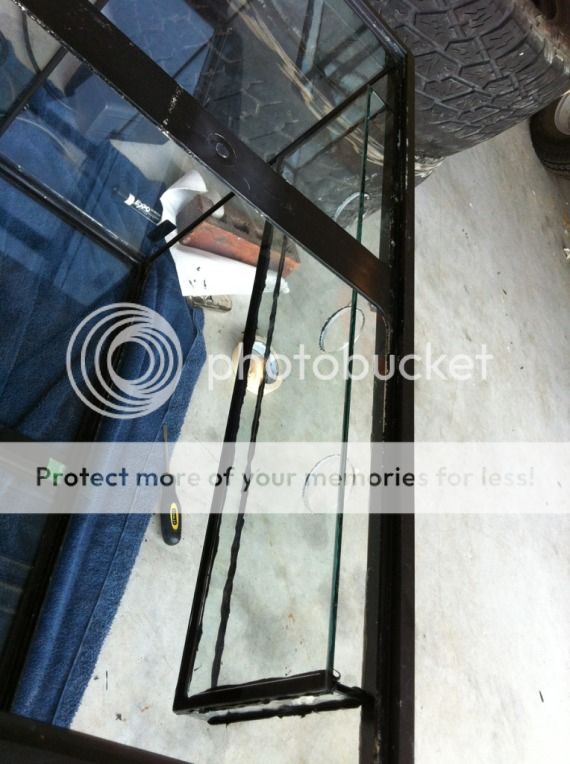

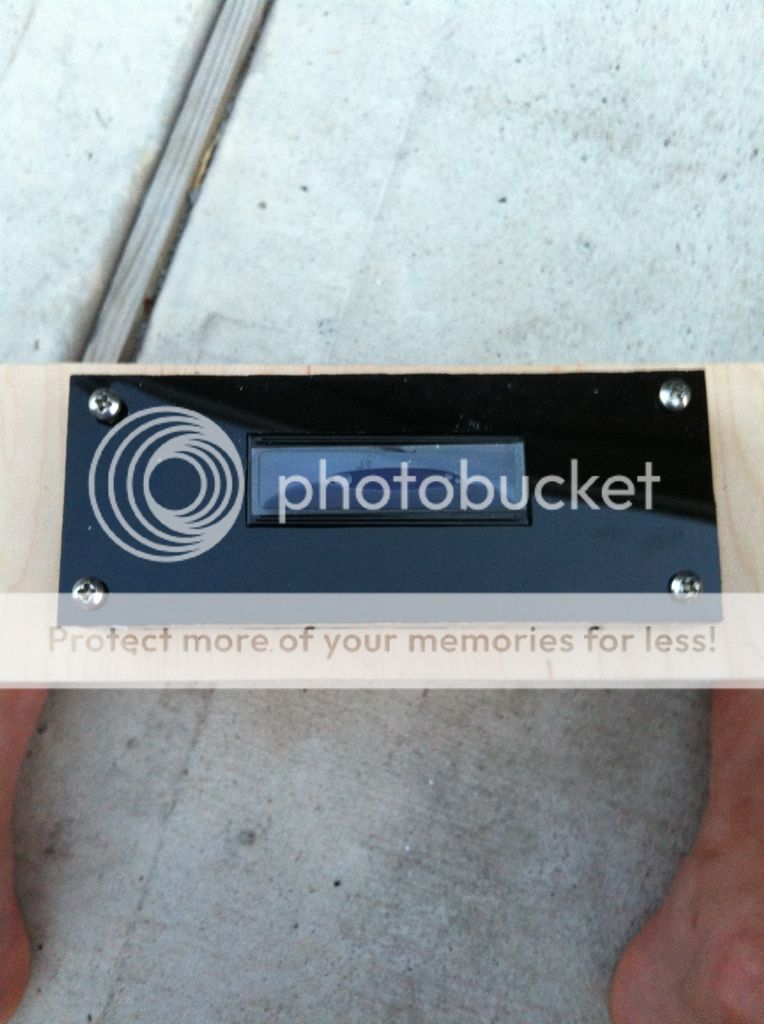

So now that I had finished making my new stand, it was time for the scary part....drilling the tank! It was extremely easy. I was nervous just like everyone else so I made a few practice holes in a piece of glass that I got from a local glass shop.

I highly advise people to use a little guide like I did. It makes it as simple as just pulling the trigger on your drill.

Success!

I originally decided to sand down the old stand and then stain it to match my cabinets (dark brown), but once I got to inspecting it, it needed to be redone. The stand was never sealed with anything so the creep had gotten to it. I took this opportunity to redesign it make a few upgrades. I wasn't happy about having to build a completely new stand though!

Notice how I extended the sides back and up to conceal my overflow and other equipment.

The top part is removable so I can look down into my external overflow box if I need to.

So now that I had finished making my new stand, it was time for the scary part....drilling the tank! It was extremely easy. I was nervous just like everyone else so I made a few practice holes in a piece of glass that I got from a local glass shop.

I highly advise people to use a little guide like I did. It makes it as simple as just pulling the trigger on your drill.

Success!