You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Official: Masterflex Calcium Reactor Setup Thread

- Thread starter tkeracer619

- Start date

Jonnywhoop

Member

Ok. Got a new issue for everyone.

I woke up this morning to find that my first chamber was half full and my second chamber was full. All the lines had air in it. My ph probe was exposed to air for who knows how long.

Any reason as to why my first chamber would be half full? My inlet from my tank is submerged. My recirculating pump is off as previously mentioned as well.

Sent from my iPhone using Tapatalk

I woke up this morning to find that my first chamber was half full and my second chamber was full. All the lines had air in it. My ph probe was exposed to air for who knows how long.

Any reason as to why my first chamber would be half full? My inlet from my tank is submerged. My recirculating pump is off as previously mentioned as well.

Sent from my iPhone using Tapatalk

Jonnywhoop

Member

It just dawned on me. Could it be the microbubbles from my skimmer since my intake is close by? Then again, can microbubbles really deplete over half a 18x5 chamber over night?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

slief

RC Sponsor

Ok. Got a new issue for everyone.

I woke up this morning to find that my first chamber was half full and my second chamber was full. All the lines had air in it. My ph probe was exposed to air for who knows how long.

Any reason as to why my first chamber would be half full? My inlet from my tank is submerged. My recirculating pump is off as previously mentioned as well.

Sent from my iPhone using Tapatalk

Are you pushing or pulling through the reactor? If pulling, I would think it could be a leak in the reactor someplace. I would go through every fitting and reseal. Teflon tape isn't ideal so if the threaded fitting have teflon tape in them, I would suggest redoing the threaded fitting and use teflon paste. I use Oatey Great White with PTFE that I get from the plumbing supply places.

If you are pushing, I would check the fittings leading into the Masterflex and make sure they are pushed all the way into the John Guest Fittings. I would check the intake side of the recirculation pump as well for leaks. You might also want to relocate the intake line away from the skimmers output as microbubbles willl make their way into the reactor.

New media takes a bit of time to become completely soaked through with water and for the air to be purged out. As such, some of the air you are seeing could be remnants of what was left in the media. I would purge the air out of the reactor and see if it accumulates again. Most recommendations are to run the reactor without gas and without the recirculation pump running for 24 hours to allow trapped air in the media to escape.

Lastly, if your Co2 rate is greater than the effluent rate coming out of the reactor, you may experience gas accumulation inside the reactor.

Last edited:

Jonnywhoop

Member

Are you pushing or pulling through the reactor? If pulling, I would think it could be a leak in the reactor someplace. I would go through every fitting and reseal. Teflon tape isn't ideal so if the threaded fitting have teflon tape in them, I would suggest redoing the threaded fitting and use teflon paste. I use Oatey Great White with PTFE that I get from the plumbing supply places.

If you are pushing, I would check the fittings leading into the Masterflex and make sure they are pushed all the way into the John Guest Fittings. I would check the intake side of the recirculation pump as well for leaks. You might also want to relocate the intake line away from the skimmers output as microbubbles willl make their way into the reactor.

New media takes a bit of time to become completely soaked through with water and for the air to be purged out. As such, some of the air you are seeing could be remnants of what was left in the media. I would purge the air out of the reactor and see if it accumulates again. Most recommendations are to run the reactor without gas and without the recirculation pump running for 24 hours to allow trapped air in the media to escape.

Lastly, if your Co2 rate is greater than the effluent rate coming out of the reactor, you may experience gas accumulation inside the reactor.

I am currently pulling. Co2 is off and I'm running the masterflex at 700ml per hour for until tomorrow or so. All the fittings seem pretty tight including the guest fittings. I have a feeling it may be the probe area.

Also, my recirculating pump is very noisy. How can I disassemble the reactor and pull the pump without spilling water all over the place? I know it's subjective to the reactor itself but some quick tips would help me solve this blue line pump issue of noise and heat.

Sent from my iPhone using Tapatalk

slief

RC Sponsor

I am currently pulling. Co2 is off and I'm running the masterflex at 700ml per hour for until tomorrow or so. All the fittings seem pretty tight including the guest fittings. I have a feeling it may be the probe area.

Also, my recirculating pump is very noisy. How can I disassemble the reactor and pull the pump without spilling water all over the place? I know it's subjective to the reactor itself but some quick tips would help me solve this blue line pump issue of noise and heat.

Sent from my iPhone using Tapatalk

Can't help you on the circulation pump. That could be messy no matter how you do it. Draining may be your best option or laying the reactor on its side. At 700ml/min, you are either pulling a vacuum leak or pulling air in from your sump. That or it is a combination of the above and air that was trapped in the media.

Jonnywhoop

Member

GREAT NEWS!

I broke everything down and took it all apart. I bought some Oatey paste and went to work. Next thing you know, I SNAPPED the blue line pump fittings. To top it off, I got paste all over my sweater.

On the bright side, i figured out where the leak was coming from. The downside is that it doesnt even MATTER because I snapped the fittings to it. I need to get the parts from MRC this week. I also figured out the pump. There were caps on the inlet and outflow of the pump completely blocking the water, so it was running dry when I temporarily had it on.

You guys have been amazing so far and I am glad I'm able to communicate with you guys on this specific thread.

To be continued....

I broke everything down and took it all apart. I bought some Oatey paste and went to work. Next thing you know, I SNAPPED the blue line pump fittings. To top it off, I got paste all over my sweater.

On the bright side, i figured out where the leak was coming from. The downside is that it doesnt even MATTER because I snapped the fittings to it. I need to get the parts from MRC this week. I also figured out the pump. There were caps on the inlet and outflow of the pump completely blocking the water, so it was running dry when I temporarily had it on.

You guys have been amazing so far and I am glad I'm able to communicate with you guys on this specific thread.

To be continued....

tkeracer619

New member

You'll get there! Glad you found the leak... and yeah that paste gets everywhere, it is almost as bad as anti seize.

OK. So Cole-Parmer just seems to give inside diameter on their tubing sizes. LS15 has a barb size of 3/16" and ID of .189" which is about the same.

https://www.masterflex.com/i/masterflex-pharmed-bpt-tubing-l-s-15-25/0650815

Can I buy the 3/16" ID tubing from this site, and use that?

http://www.usplastic.com/catalog/item.aspx?itemid=23886&catid=664

If so, then all I have to do is figure out how to connect that to my calcium reactor tubing.

I'd like to buy some of the CP tubing if you're interested. I'd like to buy 5ft of it. Please let me know asap!

Jonnywhoop

Member

Finally up and running guys!

I purged the air for 24 hours with some remnant bubbles in between the media, but I went ahead and got my co2 going since last night. My ph in the tank was around 8.3 before starting. Currently my settings are:

3psi, 3ml per minute, bubble every 10 seconds.

Should my ph2 (reactor probe) be dropping this much? My settings are already incredibly low.

My understanding is that if I go to 5ml for example, it would give the co2 a bit less time to stick to the media which will in turn get my reactor ph back up?

I won't be making any changes until tonight after I test etc.

Thanks!

Sent from my iPhone using Tapatalk

I purged the air for 24 hours with some remnant bubbles in between the media, but I went ahead and got my co2 going since last night. My ph in the tank was around 8.3 before starting. Currently my settings are:

3psi, 3ml per minute, bubble every 10 seconds.

Should my ph2 (reactor probe) be dropping this much? My settings are already incredibly low.

My understanding is that if I go to 5ml for example, it would give the co2 a bit less time to stick to the media which will in turn get my reactor ph back up?

I won't be making any changes until tonight after I test etc.

Thanks!

Sent from my iPhone using Tapatalk

slief

RC Sponsor

Finally up and running guys!

I purged the air for 24 hours with some remnant bubbles in between the media, but I went ahead and got my co2 going since last night. My ph in the tank was around 8.3 before starting. Currently my settings are:

3psi, 3ml per minute, bubble every 10 seconds.

Should my ph2 (reactor probe) be dropping this much? My settings are already incredibly low.

My understanding is that if I go to 5ml for example, it would give the co2 a bit less time to stick to the media which will in turn get my reactor ph back up?

I won't be making any changes until tonight after I test etc.

Thanks!

Sent from my iPhone using Tapatalk

Are you using a 2nd reactor to buffer the effluent? Looking at your pH graph, it looks like you have pretty large pH swings anyway so my guess is it will go back up once the lights come back on.

As for the reactor pH dropping, yes they should. While you are only running 3ml/min, 1 bubble per 10 seconds is a pretty fair amount relative to that flow rate. At 65ml/minute (20x your flow rate), I run one bubble every 2.5 seconds.. You are flowing much more Co2 relative to the effluent rate than I am so I would expect your pH to be very low in the reactor in a hurry.

Jonnywhoop

Member

Are you using a 2nd reactor to buffer the effluent? Looking at your pH graph, it looks like you have pretty large pH swings anyway so my guess is it will go back up once the lights come back on.

As for the reactor pH dropping, yes they should. While you are only running 3ml/min, 1 bubble per 10 seconds is a pretty fair amount relative to that flow rate. At 65ml/minute (20x your flow rate), I run one bubble every 2.5 seconds.. You are flowing much more Co2 relative to the effluent rate than I am so I would expect your pH to be very low in the reactor in a hurry.

Yes, I have a second chamber which should raise my effluent ph significantly especially with the low flow.

Do you recommend I bump my 3ml to 5ml then? What should my next moves be?

Sent from my iPhone using Tapatalk

slief

RC Sponsor

Yes, I have a second chamber which should raise my effluent ph significantly especially with the low flow.

Do you recommend I bump my 3ml to 5ml then? What should my next moves be?

Sent from my iPhone using Tapatalk

Your next moves should be testing your tanks alk and increasing the effluent rate to keep the tanks alk stable. It's going to take some time to figure out what effluent rate your tank needs to keep it stable but don't use the reactor to increase the alk and calcium. That should be done using 2 part before hand. That said, I would think you are going to need to increase the flow rate regardless and even so, I doubt you will need more co2 at the rates you are talking about.

Jonnywhoop

Member

Your next moves should be testing your tanks alk and increasing the effluent rate to keep the tanks alk stable. It's going to take some time to figure out what effluent rate your tank needs to keep it stable but don't use the reactor to increase the alk and calcium. That should be done using 2 part before hand. That said, I would think you are going to need to increase the flow rate regardless and even so, I doubt you will need more co2 at the rates you are talking about.

I think my psi and co2 saturation is plenty. I will go up 1mL tonight depending on my testing. I'll update you and thank you for being so attentive to my replies.

Sent from my iPhone using Tapatalk

hkgar

Active member

Johnny

How big is your tank? How big is the reactor? How much coral? There are sooo many variables that enter into the correct PH of the reactor, dKH of the effluent to maintain a stable tank dKH. Remember it is of somewhat little importance what the PSI and bubble rate are. The important thing is to determine what tank alk you want and have the reatore tuned to maintain that. The only single number that will effect that (well two numbers) effluent dKH and flow rate.

I have my reactor set at 40 ml/min and a ph of 6.44

Measure your tank ALK daily and make small adjustments to psi and/or bubble rate to match the tanks usage of alk. If you ave to get ph down below 6.4 you should than increase flow rate and at about 6.3 PH your media will start to turn to mush.

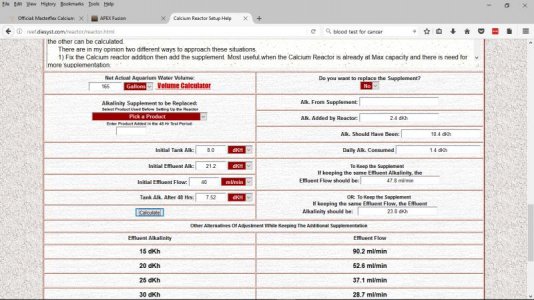

Here are some calculators to play around with to get to what you need, want.

http://reef.diesyst.com/reactor/reactor.html

How big is your tank? How big is the reactor? How much coral? There are sooo many variables that enter into the correct PH of the reactor, dKH of the effluent to maintain a stable tank dKH. Remember it is of somewhat little importance what the PSI and bubble rate are. The important thing is to determine what tank alk you want and have the reatore tuned to maintain that. The only single number that will effect that (well two numbers) effluent dKH and flow rate.

I have my reactor set at 40 ml/min and a ph of 6.44

Measure your tank ALK daily and make small adjustments to psi and/or bubble rate to match the tanks usage of alk. If you ave to get ph down below 6.4 you should than increase flow rate and at about 6.3 PH your media will start to turn to mush.

Here are some calculators to play around with to get to what you need, want.

http://reef.diesyst.com/reactor/reactor.html

slief

RC Sponsor

This is my hose wear after about two-three months use. Look about right? I just replaced the hose for the first time.

Sent from my iPhone using Tapatalk

It's probably fine. I think I've seen worse come out of mine after several months. I've got to ask.. Are you using the correct type of tubing for your head? Some heads are not designed for the pharmed norprense tubing and are instead designed to be used with the softer silicone tubing.

Im located in the Bay Area SF.

I got everything up and running. Currently running the prime to get the bubbles out. My issue now is that the Blue Line 10 pump that came with the MRC is CRAZY loud. Theres also a very obnoxiously WHINE on the start up. It als gets extremely hot to the touch..

Hopefully someone can chime in on this. In the mean while, I am running it without a recirculation pump. Will this be ok?

Not sure how large your CaRx is, bit when I subbed in a Bluline 10 for the prior Bluline 20, the pump burned up in less than 18 months. Flow was also low so now I am back to the 20. I use a lot of Bluline/PW pumps and this was the first one I didn't get at least 10 years from.

Similar threads

- Replies

- 7

- Views

- 564

- Replies

- 1

- Views

- 1K

- Replies

- 5

- Views

- 97