Hi Team Masterflex,

I'm thinking that I would like to utilize a Masterflex pump for automatic water changes, and I have a couple of questions:

1. From a reliability and low maintenance standpoint, I'm assuming that a Masterflex setup would be best (I would be using Apex to control, depending on pump model purchased - looking to use a brushless digital): Is this a good assumption?

2. I was thinking that I will need a pump with a double head on it. Will this work?

3. Assuming that the answers to questions 1 & 2 are "yes" - is there a specific model head that I should use? I have seen some talk on "occlusion"-type heads, but I was hoping I could get more details.

Thank you!

1. Absolutely, with a brushless digital you will be able to control the pump easily with the apex. Pretty much all of the digital units would be able to be integrated easily, brushless or not.

2. Yes, it's best that one of your heads have adjustable occlusion to balance the heads. I've found along with that it is best to make equal length tubing runs with a larger diameter tube to reduce losses from the tube.

3. Occlusion refers to the "pinch" of the tube. In the easy-load category of pump heads you can get them with adjustable occlusion. The heads are very precise to begin with but with most manufacturing there are tolerances. Having one head with adjustable occlusion would allow you to flow test the heads and make sure they are identical. It may not however be necessary or you may chose to go with a standard type head.

Here is the product page for easy loads.

https://www.coleparmer.com/p/master...heads-for-precision-tubing/4445?Ntt=easy+load

Some tips having done this before...

-Please use a conductivity probe on your controller and lock out the water change system if the salinity goes out of norm.

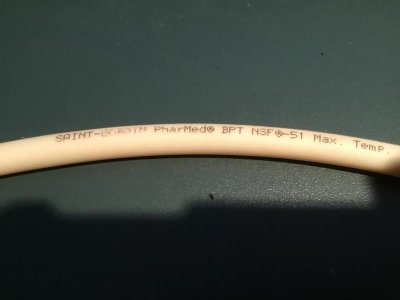

-Replace the tubing more frequently than necessary. Even though tubing sets can last years, I recommend replacing quarterly. For an auto water change setup I would recommend you do it monthly. It only takes a few minutes to keep them clean and fresh.

-Have a low float switch in your reservoir that will deactivate the system should you run low on water change water. Things happen so it is nice to have a reminder.

-Place a water leak rope or sensor at the base of the pump heads to alert you if you have a rupture. While unlikely, I feel it is better safe than sorry on a system like this.

-Aim for stainless roller heads, they tend to last longer and have tighter tolerances. When you get them replace the front and rear bearings, they're cheap and readily available.

If properly set up the system will be robust. I ran one for over a year, in fact, the only reason this thread exists is that I had a masterflex laying around after taking down the AWC system and decided to toss it on my calcium reactor. It works great for both setups.