Just sent this off to CoralVue, will be interesting to see what Jeremy suggests:

Hoping you can help me eliminate excess air and inconsistent effluent on my two reactors.

First I'll describe my setups:

1. SRO 1000: This setup is for my 75gal. frag tank.

The reactor sits on the same level as the tank, and the sump is below.

The intake is currently located in the tank itself, just below the overflow teeth. I have previously located the intake in the sump, but found that it only led to more air being trapped in the reactor.

The effluent drips to a high-flow area of the sump, the sump is directly below the tank.

To keep the effluent as consistent as possible, I have put a Cole Parmer Masterflex peristaltic pump in line with this setup.

The Masterflex is set to 115 mL/minute and is keeping parameters stable at 9-10 dKh and 430ppm Calcium.

However, I am still getting gas trapped in the reactor. The masterflex has the capacity to feed the air through the effluent line, otherwise I would lose effluent flow entirely. Prior to enlisting the Masterflex, this was the case, the effluent would cease.

The gas is mostly trapped beneath the sponge on the top of the reactor.

I have the 'gas recirc' line shut off, as I find that this only further pulverizes the gas and keeps recirculating air causing the waterblaster 1000 to become inefficient.

My CO2 tank is a considerable distance from the reactor, approx. 15' run length with airline silicon tubing.

my bubble count is very high, the bubble counter at the solenoid is too fast to count.

the bubble count on the reactor is erratic.

The tank is controlled with a solenoid and apex keeping reactor pH at 6.4-6.5

I am using brightwells CoraLazarous and NewMag for media.

I have found that within 30 days of running, the impeller body of the water blaster will collect media paste which might suggest that my pH is too low, but I am confident that 6.4-6.6 is fine for the media, and my effluent tests at 19 dKh so I know I am not over doing it with low pH.

I have it plumbed such that the masterflex is pulling effluent out of the lid - with the fitting flush to the lid, and depositing effluent to the sump.

The other lid fitting with the recessed intake is connected to the gas recirc line (which again is shut off).

I have plumbed this in both configurations (effluent from flush fitting, effluent from recessed fitting, etc) and found no real change.

So two concerns on this setup is the paste building up in the pump chamber and the air being trapped.

Otherwise, the system keeps parameters stable.

I am ultra confident that the masterflex is the saving grace.

Would a different sponge help - one that allowed the gas to escape?

What would solve the paste build up in the pump chamber?

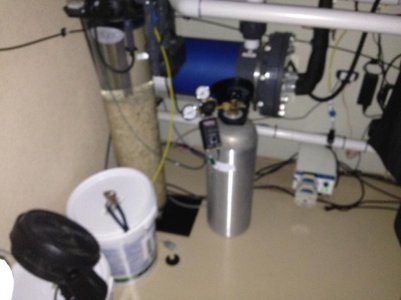

Here's a couple pics:

2. 5000D Reactor.

This is on my display. The effluent here I keep much lower, say 20mL per minute currently, since the display has no coral currently. Yet the effluent rate remains very erratic. I have not yet plumbed a masterflex to this unit but I will be doing so soon. This is a shorter run from reactor to CO2 tank, approx. 8'. There is little to no consistency in effluent.

The reactor sits on a shelf just above the sump. Intake is from the sump with 3/8" line

The gas recirc line is also shut off here, same problem as above, I find that opening the gas recirc only exacerbates the gas problem as described above.

I upgraded from 1/4" to 3/8" line to help relieve some problems. 1/4" silicon line is still used for gas supply to reactor and for the gas recirc (again this is shut off). Intake, Effluent and Chamber 1 to Chamber 2 lines are 3/8"

As you can see in the pic below the effluent on left is the flush john guest lid fitting, the chamber 1 to chamber 2 line is the recessed john guest fitting.

I have tried multiple configurations, swapping lids, fittings, etc. and remains problematic.

Suggestions?

Thanks,

-Greg