atraperegrinus

New member

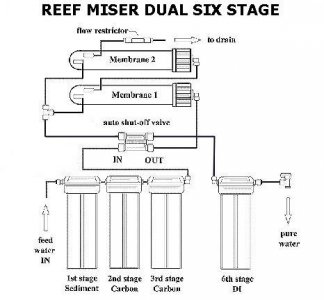

Hey guys i recently added a booster pump and a second RO membrane to my rodi filter setup, the product water has increased production correctly, but my ASO is not working properly at all, i cant seem to find a hookup diagram online with dual membranes, ASO /w float, and booster pump. I assume i have my ASO valve in the wrong spot on the lines and this is why its not working properly at the moment.

if anyone could give me some guidance as to where exactly the ASO valve has to go in relation to the booster pump and ro membranes it would be greatly appreciated.

right now I have my water line coming into my sediment and carbon filters, then to the booster pump, into the RO membranes, then through a series of twists and turns through the ASO then to di and to my container.

i know originally before i had the check valve, i had called spectrapure and they had me re-arrange it so the ASO would work correctly, and i assume where it is now is the issue since i properly added the needed check valve now. I already reached out to them earlier and hope they call soon but i was hoping maybe someone would have better luck at finding me the diagram i need to set this up properly.

thanks in advance for any help guys!

if anyone could give me some guidance as to where exactly the ASO valve has to go in relation to the booster pump and ro membranes it would be greatly appreciated.

right now I have my water line coming into my sediment and carbon filters, then to the booster pump, into the RO membranes, then through a series of twists and turns through the ASO then to di and to my container.

i know originally before i had the check valve, i had called spectrapure and they had me re-arrange it so the ASO would work correctly, and i assume where it is now is the issue since i properly added the needed check valve now. I already reached out to them earlier and hope they call soon but i was hoping maybe someone would have better luck at finding me the diagram i need to set this up properly.

thanks in advance for any help guys!