fishgate

Active member

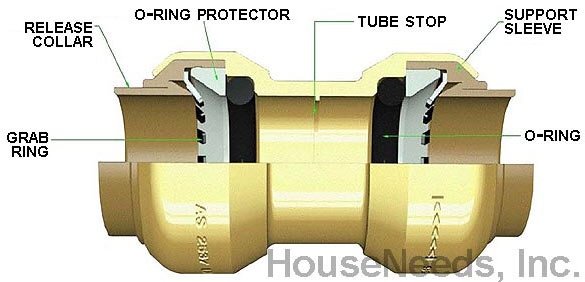

I am using SharkBite fittings for some 3/4" plumbing lines. Will the SharkBite fitting reduce the size of the opening? Like go from 3/4" to 1/2" or something like that? I don't have the fittings yet they are on order but they look like they could do this with the inner sleeve that they have.

TIA!

TIA!