Hey, Bean! I have been reading and trying to decide how I want to do this, and finally I have just decided to check with you.

I am having a tank built right now, and it has an external coast to coast overflow box on it.

First off sweet

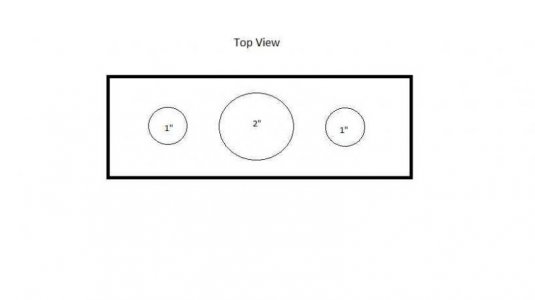

I am planning to install this drain system. So I am just curious about a few things. First of all the box will measure

40" long x 4" deep x 6" tall

#1. Should I place the drains all in one clump like you? I was thinking that spreading them out might have it's advantages, but then again maybe not. I deffer to you!

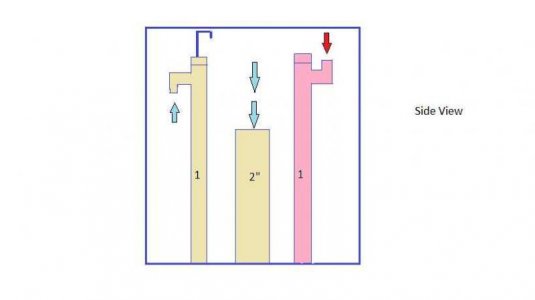

It is a personal preferance thing you main siphon will be the one with the most water coming out of it if you were to put your other pipes elsewhere it wouldn't really have that much of an effect just using more piping, unless you have plans to use the open channel pipe as a fuge feeder but even then I dont think the flow would be enough.

You can put the emergency standpipe elsewhere as well though there is not much of a benifit, I have seen people feed it directly to the return section for what ever reason it is mostly just personal preferance.

#2. Would I be better off placing the bulkheads under the box or in the rear of it. Just asking since I will have both options

Again this is personal preferance thing it look much cleaner in my opinion to have them coming out of the bottom so you dont have the add the 5" or 6" that it would take up coming out of the rear.

#3. If I place them in the back, what height would be good, so that my elbows will be close to the bottom of the box. In order to keep fish, etc out of the drains!!

Don't go through the bottom

Thanks

NathanS