When I first started in the reef hobby (8 yrs ago) I was very scared of sumps because of the possibility of overflowing all over the floor whether by error or equipment malfunction. So for the first few years I did not use a sump at all. Later on I figured out all of the details and was able to feel confident that my current "standard" sump system is reasonably safe from that possibility.

All along though I've had this Idea that I just can't get away from: "There's GOT to be a way to have sumps be sealed." I think about people who are just getting into the hobby and can NOT have even a remote possibility of Water on their floor. But also seasoned experts having just the extra level of confidence that there is no way for this system to overflow.

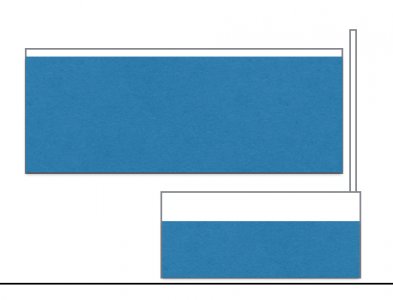

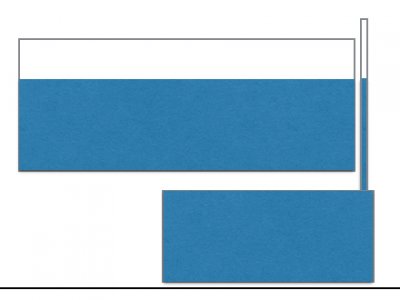

I've been sort of researching the idea for the last 8 years and I really think the answer could be a "Snorkel" sump. I've included 2 pictures, 1st of normal operation and the 2nd of a fail mode where the return pump or the overflow has failed in some way. In the Snorkel Sump, the entire sump is sealed but the snorkel extends up past the display tank water level and is wide open to the atmosphere.The snorkel therefor eliminates any issues with pressure differentials or fluctuations between the two tanks or a build up of pressure in the sump. In normal operation the Snorkel Sump operates exactly like any other sump, but if something happens all of the water will simply settle out to some level without overflowing. But there are some other potential "issues". I'm interested in getting some feedback on what some of those issues could be. I've already thought of a few of them and think that they are fairly easy to get around.

1) The Inlet and Outlet of the sump would all need to be sealed - answer -> bulkheads.

2) Wires going into the sump for ATO, etc - answer ->again pretty sure some type of bulkheads would work.

3) Filter Socks - answer -> inline filter cartridges, other?

4) General access to the sump for macro algae export, pump replacement, etc. - answer -> some type of easy access "port-hole".

5) Protein Skimmer - answer -> I don't really have an answer for this one but feel that there could be some solution like a remote skimmer?

Also I am aware that even though the snorkel solves part of the Pressure issue, there is still a "weight of the water at X height" issue. This part is maybe tricky - and I'm not an engineer but from what I've read I think this could be resolved with a "moderate" increase in the thickness of the plexiglass. A 4-5 foot high top of your display tank water level would be roughly 8 to 10 psi of "pressure" in the sump which is certainly not trivial but also I think not outrageous to manufacture to. Any Engineers out there who could verify that and translate it to some real numbers for thickness? Ultimately this equation could be turned into a "calculator" where you plug in the dimensions and it gives you a target thickness.

Go ahead and shoot holes in the idea guys you won't hurt my feelings any. But I still think - "There's GOT to be a way!"

All along though I've had this Idea that I just can't get away from: "There's GOT to be a way to have sumps be sealed." I think about people who are just getting into the hobby and can NOT have even a remote possibility of Water on their floor. But also seasoned experts having just the extra level of confidence that there is no way for this system to overflow.

I've been sort of researching the idea for the last 8 years and I really think the answer could be a "Snorkel" sump. I've included 2 pictures, 1st of normal operation and the 2nd of a fail mode where the return pump or the overflow has failed in some way. In the Snorkel Sump, the entire sump is sealed but the snorkel extends up past the display tank water level and is wide open to the atmosphere.The snorkel therefor eliminates any issues with pressure differentials or fluctuations between the two tanks or a build up of pressure in the sump. In normal operation the Snorkel Sump operates exactly like any other sump, but if something happens all of the water will simply settle out to some level without overflowing. But there are some other potential "issues". I'm interested in getting some feedback on what some of those issues could be. I've already thought of a few of them and think that they are fairly easy to get around.

1) The Inlet and Outlet of the sump would all need to be sealed - answer -> bulkheads.

2) Wires going into the sump for ATO, etc - answer ->again pretty sure some type of bulkheads would work.

3) Filter Socks - answer -> inline filter cartridges, other?

4) General access to the sump for macro algae export, pump replacement, etc. - answer -> some type of easy access "port-hole".

5) Protein Skimmer - answer -> I don't really have an answer for this one but feel that there could be some solution like a remote skimmer?

Also I am aware that even though the snorkel solves part of the Pressure issue, there is still a "weight of the water at X height" issue. This part is maybe tricky - and I'm not an engineer but from what I've read I think this could be resolved with a "moderate" increase in the thickness of the plexiglass. A 4-5 foot high top of your display tank water level would be roughly 8 to 10 psi of "pressure" in the sump which is certainly not trivial but also I think not outrageous to manufacture to. Any Engineers out there who could verify that and translate it to some real numbers for thickness? Ultimately this equation could be turned into a "calculator" where you plug in the dimensions and it gives you a target thickness.

Go ahead and shoot holes in the idea guys you won't hurt my feelings any. But I still think - "There's GOT to be a way!"