SnowManSnow

Member

Hi guys I'm pretty sure I know what to do here, but I just want some confirmation before I screw anything up.

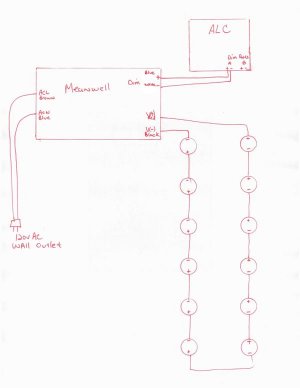

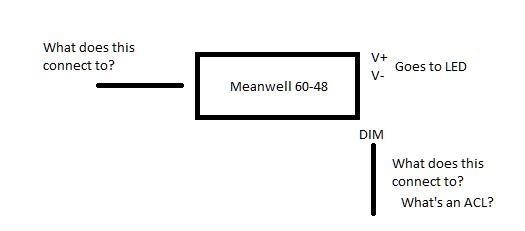

ON the 48 D I have AC IN with a brown and blue wire. These Go..... ?

Does it matter which I wire to which on the plug?

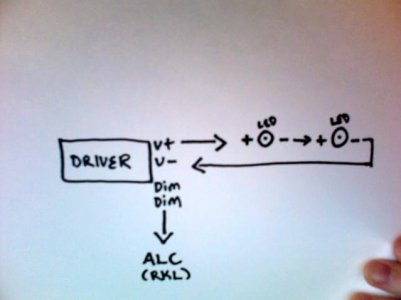

I also have a V+ (red) and a V- (black) .. in detail where do THESE go?

I also have a DIM + (blue) and a DIM - (white)... same as above please.

AS A NOTE I will be using the ALC with my RKL on this project.

________

Internal trim. I've seen several references to adjusting this before any power goes through the driver. What do I do with it? Turn all the way down? (counterclockwise)... and then back it back up? Just a little confused as to WHY ..

Thanks.

B

ON the 48 D I have AC IN with a brown and blue wire. These Go..... ?

Does it matter which I wire to which on the plug?

I also have a V+ (red) and a V- (black) .. in detail where do THESE go?

I also have a DIM + (blue) and a DIM - (white)... same as above please.

AS A NOTE I will be using the ALC with my RKL on this project.

________

Internal trim. I've seen several references to adjusting this before any power goes through the driver. What do I do with it? Turn all the way down? (counterclockwise)... and then back it back up? Just a little confused as to WHY ..

Thanks.

B