Phixer,

Could a 6" perimeter brace and between access holes on the top work instead of the current 8"?

I have a 48"x48"x24" cube made out of 3/4" acrylic and there is zero bowing. It has a 3/4" top with a 6" euro style brace only and I really like how its still open enough to do work on the bottom corners of the tank.

Hi KMU, many combinantions will work. Is that cube 24" tall? If so 3/4 is fine for a 24" height.

How long do you want it to last?

Will answer this way, because it's best to know why.

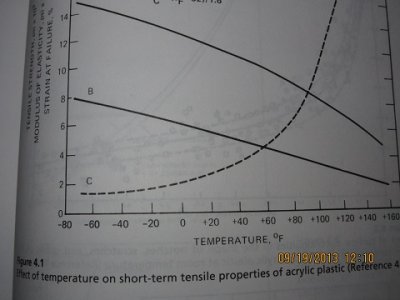

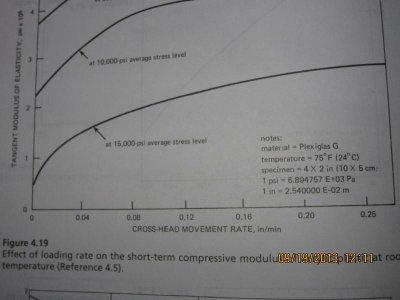

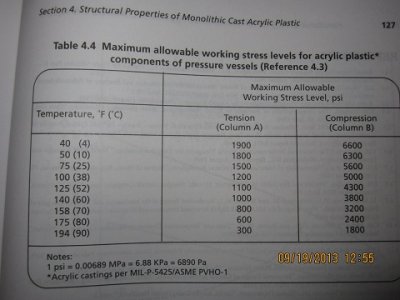

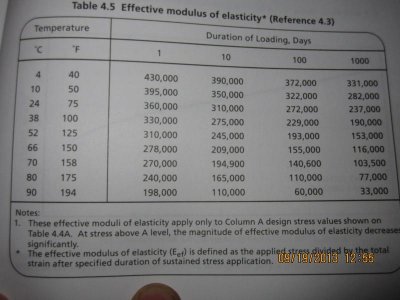

Will try not to be long winded. The physical properties of acrylic for our applications (aquarium building) are pretty much a function of temperature and sustained pressure over time in addition to UV exposure. Different than diving where these factors are constantly changing. The science used to determine what works best per given application is called Finite Element Analysis (FEA). There is another term known in the industry as modulus of elasticity but I wont go into it here, would take a long time. Even if you cant see percievable bowing the stress is there, much greater when you observe significant deflection. When determining your dimensions (including thickness) all things should be considered. Most MFGs dont do the math and will have no idea what your talking about when using these terms, they just build and several years later the tanks begin to craze. Not the right way to build IMO. However, aquariums differ from diving applications because they are subjected to continuous sustained static pressure over longer periods of time (slight psi changes during water changes). Although less total pressure it becomes a function of time/pressure and temp. That makes acrylic subjected to saltwater a pretty hostile environment. That being said...

For your application it's important to understand what the tensile strength of the bond seams are capable of supporting as these are normally the weakest link in a polymerizable joint (solvent is a totally different animal and not what I would use for 1.25" which is what I would use for 36" height. Remembering this is 1" at a height of 36" (not what I would recommend) and that the top of the tank being closer to the lights is subjected to more heat and UV light, these factors must be considered if you want the tank to last a long time.

Considering a temp of 85F a designer can specify the thickness of the panel to insure that its long term creep deflection (bowing) does not exceed specified design limits. The creep modulus for acrylic for a 30 year loading duration with a temp range from 30-100F varies from 270,000 to 160,000psi respectively. Whether a panel will fail while filling the aquarium with water can be caluculated either analytically or with the aid of FEA. If the max flexure stress exceeds the short-term flexure strength of acrylic, the panel will rupture. The min short term flexure strength for acrylic is 14,000psi at 75F and 12,000psi at 100F. Handbook of Acrylics pg182.

Much more math, PM me and I'll explain.

There is a real economic incentive to using thinner material, but there is a trade off. Keeping the maximum pressure well below these limits per wall thickness and the tensile strength of the cement will ensure longer life. If done right these joints will never see pressure close enough to what they are capable of handling.

So what does this all mean? How long do you want the tank to last?

I wouldnt go any thinner than 8" considering 1" thick material at 36".