karimwassef

Active member

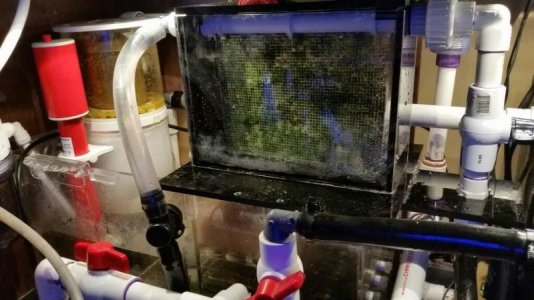

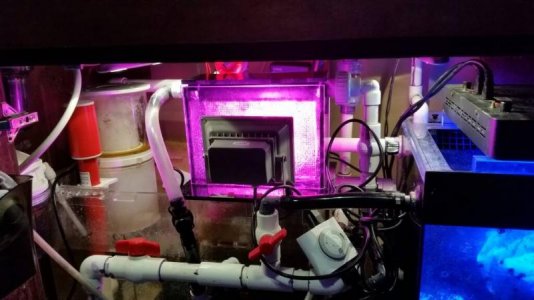

There's no attachment that completely eliminates the interface effect. I tried many options

<a href="http://s1062.photobucket.com/user/karimwassef/media/IMG_5446_zpsyfg9cyy7.jpg.html" target="_blank"><img src="http://i1062.photobucket.com/albums/t496/karimwassef/IMG_5446_zpsyfg9cyy7.jpg" border="0" alt=" photo IMG_5446_zpsyfg9cyy7.jpg"/></a>

<a href="http://s1062.photobucket.com/user/karimwassef/media/IMG_5444_zpszpbsikvc.jpg.html" target="_blank"><img src="http://i1062.photobucket.com/albums/t496/karimwassef/IMG_5444_zpszpbsikvc.jpg" border="0" alt=" photo IMG_5444_zpszpbsikvc.jpg"/></a>

<a href="http://s1062.photobucket.com/user/karimwassef/media/IMG_5425_zpsuzxdaaxd.jpg.html" target="_blank"><img src="http://i1062.photobucket.com/albums/t496/karimwassef/IMG_5425_zpsuzxdaaxd.jpg" border="0" alt=" photo IMG_5425_zpsuzxdaaxd.jpg"/></a>

<a href="http://s1062.photobucket.com/user/karimwassef/media/IMG_5423_zpssvswgfo9.jpg.html" target="_blank"><img src="http://i1062.photobucket.com/albums/t496/karimwassef/IMG_5423_zpssvswgfo9.jpg" border="0" alt=" photo IMG_5423_zpssvswgfo9.jpg"/></a>

And then settled on a double capped tiny zip tie. I cut the heads off and use a straight strip with two caps to line everything up

<a href="http://s1062.photobucket.com/user/karimwassef/media/IMG_5441_zpsd81xov77.jpg.html" target="_blank"><img src="http://i1062.photobucket.com/albums/t496/karimwassef/IMG_5441_zpsd81xov77.jpg" border="0" alt=" photo IMG_5441_zpsd81xov77.jpg"/></a>

<a href="http://s1062.photobucket.com/user/karimwassef/media/IMG_5442_zpsb0b0xiip.jpg.html" target="_blank"><img src="http://i1062.photobucket.com/albums/t496/karimwassef/IMG_5442_zpsb0b0xiip.jpg" border="0" alt=" photo IMG_5442_zpsb0b0xiip.jpg"/></a>

<a href="http://s1062.photobucket.com/user/karimwassef/media/IMG_5443_zpsfwxlgiuj.jpg.html" target="_blank"><img src="http://i1062.photobucket.com/albums/t496/karimwassef/IMG_5443_zpsfwxlgiuj.jpg" border="0" alt=" photo IMG_5443_zpsfwxlgiuj.jpg"/></a>

This had the smallest profile and was still rigid. I also wanted to be able to detach the sheets individually

I don't know how well it'll work at my very high flow rate. I'll experiment and report.

I could glue them with epoxy and then sand it down but then they're not detachable.

I could sew them end to end but the interface and nylon thread could make the water jump anyway. Also makes separation more difficult.

<a href="http://s1062.photobucket.com/user/karimwassef/media/IMG_5446_zpsyfg9cyy7.jpg.html" target="_blank"><img src="http://i1062.photobucket.com/albums/t496/karimwassef/IMG_5446_zpsyfg9cyy7.jpg" border="0" alt=" photo IMG_5446_zpsyfg9cyy7.jpg"/></a>

<a href="http://s1062.photobucket.com/user/karimwassef/media/IMG_5444_zpszpbsikvc.jpg.html" target="_blank"><img src="http://i1062.photobucket.com/albums/t496/karimwassef/IMG_5444_zpszpbsikvc.jpg" border="0" alt=" photo IMG_5444_zpszpbsikvc.jpg"/></a>

<a href="http://s1062.photobucket.com/user/karimwassef/media/IMG_5425_zpsuzxdaaxd.jpg.html" target="_blank"><img src="http://i1062.photobucket.com/albums/t496/karimwassef/IMG_5425_zpsuzxdaaxd.jpg" border="0" alt=" photo IMG_5425_zpsuzxdaaxd.jpg"/></a>

<a href="http://s1062.photobucket.com/user/karimwassef/media/IMG_5423_zpssvswgfo9.jpg.html" target="_blank"><img src="http://i1062.photobucket.com/albums/t496/karimwassef/IMG_5423_zpssvswgfo9.jpg" border="0" alt=" photo IMG_5423_zpssvswgfo9.jpg"/></a>

And then settled on a double capped tiny zip tie. I cut the heads off and use a straight strip with two caps to line everything up

<a href="http://s1062.photobucket.com/user/karimwassef/media/IMG_5441_zpsd81xov77.jpg.html" target="_blank"><img src="http://i1062.photobucket.com/albums/t496/karimwassef/IMG_5441_zpsd81xov77.jpg" border="0" alt=" photo IMG_5441_zpsd81xov77.jpg"/></a>

<a href="http://s1062.photobucket.com/user/karimwassef/media/IMG_5442_zpsb0b0xiip.jpg.html" target="_blank"><img src="http://i1062.photobucket.com/albums/t496/karimwassef/IMG_5442_zpsb0b0xiip.jpg" border="0" alt=" photo IMG_5442_zpsb0b0xiip.jpg"/></a>

<a href="http://s1062.photobucket.com/user/karimwassef/media/IMG_5443_zpsfwxlgiuj.jpg.html" target="_blank"><img src="http://i1062.photobucket.com/albums/t496/karimwassef/IMG_5443_zpsfwxlgiuj.jpg" border="0" alt=" photo IMG_5443_zpsfwxlgiuj.jpg"/></a>

This had the smallest profile and was still rigid. I also wanted to be able to detach the sheets individually

I don't know how well it'll work at my very high flow rate. I'll experiment and report.

I could glue them with epoxy and then sand it down but then they're not detachable.

I could sew them end to end but the interface and nylon thread could make the water jump anyway. Also makes separation more difficult.