My comment might be too late but it's not a huge deal...side drains are very inefficient. The issue seems to be related to flow dynamics.

A bottom drain with a straight shot down where the pipe terminates under the waterline will work a couple different ways, but primarily it will try to siphon. So if the incoming flow is too low for the volume the drain can handle but high enough to close off the pipe, it will gurgle and flush. Adding a valve will allow you to tune it so that it won't siphon and flush or gurgle, but you have to get it dead on perfect without a secondary drain (and it has to stay balanced perfectly, tricky)

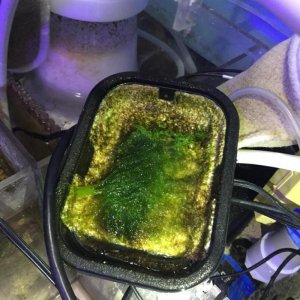

my experience is that a side drain doens't work quite the same but admittedly I never put a control valve on a side drain, so theoretically it should be tunable, but the entire opening would have to be sumberged, or you would have to have a drain on the other side that is roughly at the same level (maybe 1/4 to 1/2 diameter higher), so that the "balanced" flow water level in the box was maintained even though it was not covering the entire bulkhead opening, the siphon would "start" actually inside the pipe at the elbow. Hard to explain in writing but the valve on the side drain would control the level in the side drain pipe so that it was at the same level as inside the box, or maybe only slightly below it, maybe 1/2 way up the opening of the bulkhead. The issue is that if you start to get higher and are almost covering up the entire bulkhead inside the box, the water motion will suck water in and you will get microbubbles galore as well as sucking noises. so a 1" pipe size bulkhead is going to be difficult on a side drain, looks like you're using maybe 1.5 or 1.25 so that's better.

I can tell you without a doubt that the high side drain is not going to do anything for you - at all. Trust me on this one, I've made them with a high secondary/emergency drain and it doesn't work like you expect, it'll be like it's not there at all. I've made them with a very low secondary drain (with a primary bottom drain) and even that doesn't work as well as you think. Don't feel bad, there are several manufacturers out there building systems with drains configured like this, low side drain, high secondary, and lots of DIYers following that design, so one would think that this is the way to go - and it's not a horrible idea to have a high secondary drain, because it does offer some level of protection, but it's far from a 100% fail safe. If you have a 100% sudden blockage of the primary drain, the box will quickly fill up and very likely overflow, because side drain flow dynamics really suck.

I would made the secondary just slightly above the level of the primary, maybe 1/2" above it or so. Am I right that those are 1.5" side drains or are then 1.25"? They look larger than 1"

Also use Street Elbows through the uniseals if you want to save yourself some side-to-side space