You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Algae Scrubber Basics

- Thread starter srusso

- Start date

Floyd R Turbo

Either busy or sleeping

Not sure, but the main absorption spectrum for algae is in the deep red range, there isn't much in orange really.

Dactylopterus

New member

Would orange LEDS be a plus if added to red and blue for a scrubber?

No benefit added using orange LEDs

A good option. What are the actual demensions of one of those? (depth included) I didn't see any specified in my quick glance of the add.

Some of the most compact lights I've seen, however, are DIYs. The thickness of a heatsink and the LEDs themselves, and that's it... Depending on your heat sync, you can make some pretty compact lights.

BCool - didn't you DIY with some LED strips? How are those working out for you?

No, I used the flood and it is working great!

I have finally connected my scrubber. Should the water be sheeting down the plastic mesh equally across it's full width? Mine is falling in 'rivulets' rather than sheeting down, with more flow towards the middle and less on the sides. I am thinking perhaps my slot is too wide or I am not running enough flow. Picture of the one I built in post #5278

Floyd R Turbo

Either busy or sleeping

I have finally connected my scrubber. Should the water be sheeting down the plastic mesh equally across it's full width? Mine is falling in 'rivulets' rather than sheeting down, with more flow towards the middle and less on the sides. I am thinking perhaps my slot is too wide or I am not running enough flow. Picture of the one I built in post #5278

With a bare screen, it will take a few days or even a few weeks for the water to flow evenly across it. Once you start getting some growth (usually diatoms, etc) then those will force the water to "slow down" a bit, and the water will spread out. So I would just leave it be for a week, if it's not spreading out at all, then start looking for a culprit

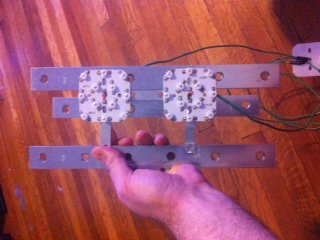

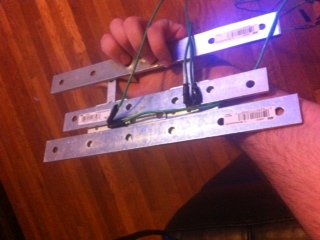

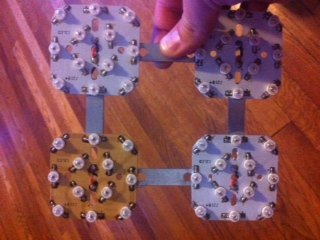

Question about LED running temperatures. In a general sense, how hot is too hot? I have made a few scrubbers thanks to this thread, the most successful was a horizontal due to cabinet configuration, but now I have decided to make the vertical one work/fit. I am using already made 12w (12 individual 1w per grow lamp) LED grow lights that I removed the LED panels from, scrapped the lenses, and then rewired the drivers together in a different configuration to basically have free LED plate and driver. I have 4 of these (so 48watts) on each side of an 8X10 screen. Each 1w LED is attached to an aluminum backing and these get darn hot obviously. The "heat sink" provided by the fixture's body did a poor job. So I've attached some very thick mending plates to the backs of the aluminum plates to dissipate heat. I think its working pretty well but it made me wonder. Now that I can't rely/blame someone else's design, what should I be looking for in terms or heat dissipation? How much heat can these things really handle? Just trying to be safe about it. Thanks for any input!

Floyd R Turbo

Either busy or sleeping

I think pics would really help - too hard to describe in words....

Chris Abbott

New member

I believe all they are asking is what is the optimal operating temperature of an led and at what temperature should they look into redesigning their heatsink.

Try the led / DIY section cause IDK.

Try the led / DIY section cause IDK.

Floyd R Turbo

Either busy or sleeping

Since deep reds only run at 650-700mA, they should be pretty easy to keep cool. My heat sink is oversized for the use, so I can hold my hand on it, even with a temp gun it only registers about 100F right under the LED. If yours is so hot that you can't touch it, then you need a fan on it or a better heat sink. 1W LEDs (I and totally guessing here) dissipate probably about 75% of the heat of a 3W LED (talking 660s here) and you would probably need more of them to get the same level of intensity, so they would probably use the same size heat sink.

My main question was regarding your description of the "aluminum backing", I'm assuming you mean the heat sink? Or are you talking about the PCB the LED is attached to? That's why I wanted a pic.

My main question was regarding your description of the "aluminum backing", I'm assuming you mean the heat sink? Or are you talking about the PCB the LED is attached to? That's why I wanted a pic.

Exactly- the aluminum backing was the mini heat sink the 1watt LEDs are glued to too. That sits in a much larger housing that resembles the shape of a lightbulb- which I removed. The little aluminum one gets scorching. The heat sink I have now will still feel uncomfortable if your hand was there for more than a few seconds but wouldn't burn you by any means. I will post pics this weekend for some input. Thanks again for the input this far!

With a bare screen, it will take a few days or even a few weeks for the water to flow evenly across it. Once you start getting some growth (usually diatoms, etc) then those will force the water to "slow down" a bit, and the water will spread out. So I would just leave it be for a week, if it's not spreading out at all, then start looking for a culprit

Two days running, no algae growth, no nitrate reductions - these things clearly don't work ...... :lolspin:

Jokes aside, thx for the tip. No sign of any growth yet, but water flow has already evened out some. Not sure I roughed up the screen enough tho.

JHawlz9989

New member

So one of the issues I've been having is limited algae growth, but a bunch of clear sludge, which I think is bacteria growth. Now the scrubber was working in that I could harvest the bacteria just as I did the algae, but I was wondering what was contributing to bacteria growth as opposed to algae growth? Any ideas?

Josh

Josh

Floyd R Turbo

Either busy or sleeping

When you say "clear sludge", it is literally just clear, or is it more of a gelatinous substance that is green in color but somewhat translucent?

JHawlz9989

New member

It's literally just like clear gelatin. From what I read in an advanced aquarist article, it's most likely a massive bacteria colony. There are some colored patches where there's a bit of algae mixed in, but for the most part it's clear. I'll try and get a good picture, but it can be somewhat difficult to photograph.

Josh

Josh

Floyd R Turbo

Either busy or sleeping

Oh, dude, no wonder this thing was so hot! That is a completely inadequate amount of aluminum for dissipating that heat. Unless you have a fan on the backside of each of those aluminum secitons, those are going to burn up in no time.

Sweet it worked, sortof. OK so the bottom most picture is the 4 individual LED arrays attached to one another. The top most picture shows this from the back and shows the aluminum "backing" of the LEDs (the square). The middle 2 pictures were an experiment to see how much heat would be dissipated with some thick mending plates. left alone, the arrays get scorching hot but they keep on going. With the plates on them, they are hot but you can leave your hand on them. So...not sure where to go from this experiment. Maybe getting a dedicated heat sink for these things?

Floyd R Turbo

Either busy or sleeping

Exactly- the aluminum backing was the mini heat sink the 1watt LEDs are glued to too. That sits in a much larger housing that resembles the shape of a lightbulb- which I removed. The little aluminum one gets scorching. The heat sink I have now will still feel uncomfortable if your hand was there for more than a few seconds but wouldn't burn you by any means. I will post pics this weekend for some input. Thanks again for the input this far!

The "mini heat sink" you refer to is not a heat sink at all - it is a metal-core PCB (printed circuit board). This is just a larger version of a "star" PCB. This needs to be mounted to an appropriately sized aluminum heat sink. Some LED manufacturers mount these PCBs to a flat sheet of aluminum and then put a fan blowing on that sheet, this is also a good way to do it. You can probably mount these to a decent finned heat sink and get away with no fan but those flat bars are doing nothing

EDIT: I shouldn't say the are doing nothing, but in adequate. At a minimum (the cheap route) you want a bunch of "U" channel aluminum stacked up to form a "finned" heat sink

haha yea I know. They had those "bulbs" on them but were really poorly made and also wouldn't fit so I had to remove the arrays and rewire the drivers. I guess I'll search for heat sinks and if that doesn't cool them down enough I'll add fans. Burning out is one thing, I'm not to proficient at understanding what these things can tolerate so I was scared of a fire.

Similar threads

- Replies

- 9

- Views

- 216

- Replies

- 0

- Views

- 335