Reef_Matrix29

Water Lover

I currently do not use any "sealant" over my LED's, but rather have the array suspended 6 - 8 inches off the water level and circulation to help reduce salt spray; I'm sure that over time some will deposit, but no plans for prevention just yet.

You are planning 4 x 100W T5's and 60 LED's? I have a hybrid system now too, but you seem like your tank is T5 dominated and the LED's are the accent light. I would suggest more LED's and perhaps not overdriving your bulbs unless your corals aren't taking to the light put out by the configuration.

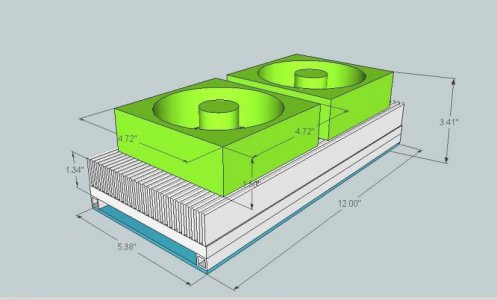

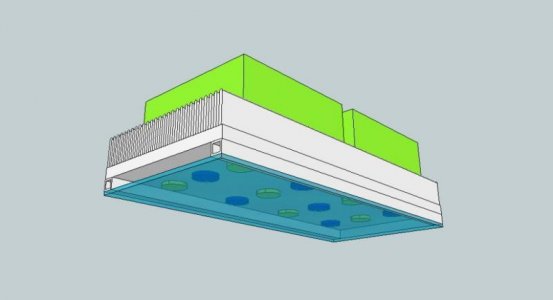

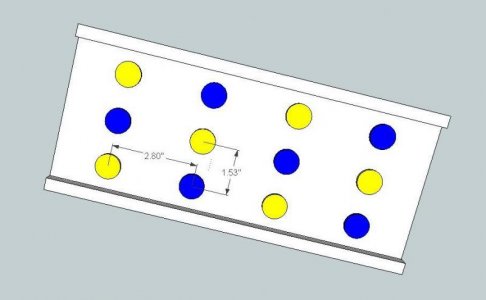

I'm still a little confused about how your canopy will look and the need for 6 heatsinks, maybe a hand drawn picture would help us visualize it better. When I upgrade to a 120G, I'm planning on just 2 heatsinks @ 24 x 12.5.....if I can get 24 x 18 would be even better, but still no more than two for me. In my experience you don't get spotlighting with no optics, so you can space them how you wish, but you will have uneven coverage. Spot-lighting is with optic usage and if you have an area that needs deeper penetration, you could pre-design for certain sections of your array to have optics on them and pack non-optic LED's around it to "light" the shade caused by the focused beam. (hope that made sense)

You are planning 4 x 100W T5's and 60 LED's? I have a hybrid system now too, but you seem like your tank is T5 dominated and the LED's are the accent light. I would suggest more LED's and perhaps not overdriving your bulbs unless your corals aren't taking to the light put out by the configuration.

I'm still a little confused about how your canopy will look and the need for 6 heatsinks, maybe a hand drawn picture would help us visualize it better. When I upgrade to a 120G, I'm planning on just 2 heatsinks @ 24 x 12.5.....if I can get 24 x 18 would be even better, but still no more than two for me. In my experience you don't get spotlighting with no optics, so you can space them how you wish, but you will have uneven coverage. Spot-lighting is with optic usage and if you have an area that needs deeper penetration, you could pre-design for certain sections of your array to have optics on them and pack non-optic LED's around it to "light" the shade caused by the focused beam. (hope that made sense)