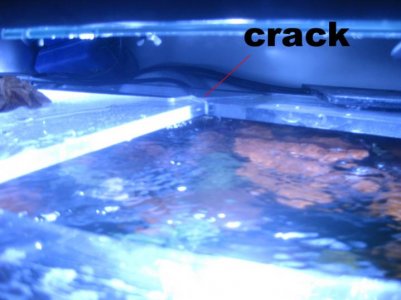

I did my stand last night, but it will not fit my 55 gallon sump

MY sump is 48" long by 18" wide

My main tank is a 120 4'x2'x2'

Now i have to take everything apart again, all that wasted wood

Please tell me how to make a stand for a 120 tank, with a 48" Sump below also, Thanks !

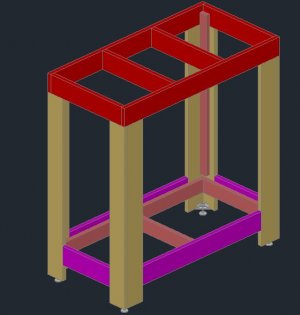

Will you ever want to get your sump out of the stand, or is it okay to build your stand around your sump? You can fit your sump under your stand, but you will not be able to get it out through the front of the stand. If you have 48" clear to either side of your stand, you would be able to slide your sump out side-ways. Here's how:

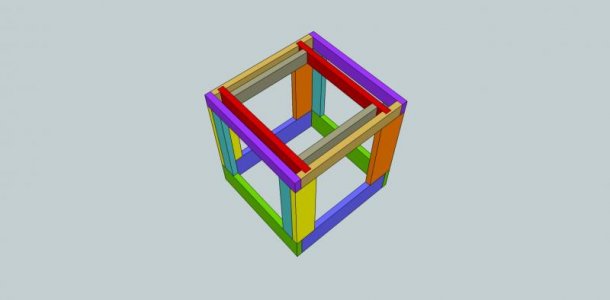

Look at the basic design of the stands on this thread:

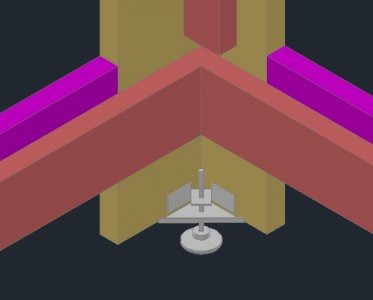

Each leg is made up of two 2x4's (purple). Trim the width of one of them from 3.5" down to 3", and use that more narrow one for the part of the leg that faces the side of the stand (or instead of trimming, you could use a 2x3 instead of a 2x4). Now the gap between the purple pieces along the side, for a 24" wide tank would be 24-3-3= 18". That will work in theory, but in reality you need to design in about 1/8"-3/16" of space on each side of your sump, and your sump probably isn't exactly 18" wide. Carefully measure the bottom (and top) frame of your sump, and your tank, and size the yellow and blue pieces so that they are 3.25"-3.375" longer than your sump width. Then make sure that the frame of your tank will still be completely supported by the red pieces. I always make a careful drawing, like the one above, label the distances, add them up, and make sure it's all going to work before I build a stand ("measure twice, cut once") (needing to rebuild stinks, and needing to rebuild twice can lead to holes in the wall and broken knuckles, and stroke)

BTW: Notice that the thickness of the leg, plus the tacking strip, is 3", so even if you use a 2x3 (2.5" wide) instead of a 2x4 trimmed down to 3", you still have a total of 3" of wood in front of, and behind, your sump, not just 5".

The ends of the sump would be resting on the blue pieces, which would not be enough support for the sump, so you will need to run 2x4's under the long edges of the sump (similar to the red beams) to support it. Also, be sure to arrange the two pieces of wood for each leg exactly as you see them in the picture. If you reverse them, then you'll use up 3" of that 19" gap and be up the creek again (sans paddle)

Possible problems I see in your picture:

Your picture makes it look like there is a little gap between the top of your front legs and the bottom of the front horizontal beam. If so, then the weight on the beam will be hanging on the screws in the tacking strip (green pieces) instead of resting on the top of the legs.

It also looks like the tacking strips touch the floor. The should be at least 1/8" above the floor, so that all the weight will rest on the legs, and none on the tacking strip.