I would disagree on that idea. It is a nailer, an artifact from a design where there needs to be a board to "catch" the edge of drywall sheets so they can be nailed up without sagging. The design did not transition completely from wood house framing to "furniture". The crossbars don't have the rigidity they would need to prevent spreading or warping. Even if attached with really serious metal joist hangers, they would fail if the front or back rail of the stand began to warp or twist. Screws and glue don't have a chance.

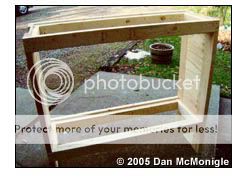

If warping is a possible issue the approach in the photo would address it. This shows a stand just before plywood panels are placed on the shelves. The inner edges of the doubled rails drop down by the thickness of the plywood being used. Once screwed and glued in place, the rails are tied together enough that warping or twisting would be minimized without pulling joints apart as would happen with a crossbar.

Painted, back-braced, and ready for doors, this picture shows the plywood in place on the shelves for the tank and the sump.

I agree with you here completely. The reason for a center post, or an offset post, is to hang doors on, or as a backstop for the door latches. Otherwise it is just something that will get in the way and possibly warp or twist something else that would have been fine.

We can go with a "green" concept and have less wood and more strength, or just throw wood and metal brackets at a design, which could actually weaken it with extraneous non-functional pieces.