A couple of questions regarding your setup-

How large of a sand filter are you using?

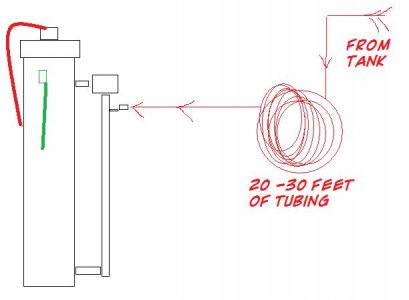

My BIO has +- 30 liter +- 8 gal of sand. I use sand because it is very cheep. My first system was based on the advise of Frank De Graaf. This was in 1972. The system was based on the bio, a trickle filter in that time. Because of the expense water was changed only when really necessary because of very high nitrate levels. Our big problem was eliminating nitrate build up; The SD solves this problem. I still use a sand filter because I want to be sure the nitrification cycle is completed and ammonium and nitrite is eliminated as soon as possible. The rector is fluidized by the system pump with a rate over of +- 3000l/h and is installed after a aqua medic flotor 5000. The SD is seeded with BIO filtered water which is low on oxygen

With the size of your system, what size SD reactor are you running? Does the diameter of the SD reactor have an impact on its effectiveness ( does a 4" reactor filled with a gallon of media work better than a 6" reactor filled with a gallon of media)?

I advise 1% sulfur( 100 gal system 1 gal sulfur) with a working en-fluent between one to five times the amount of sulfur per hour.

My system ( 6000l) has 30l of sulfur ( 0,5%) and for the moment a stable en-fluent of 120l/h for 0 nitrate output. This don't mean that the system has 0 nitrate. The system is never without nitrate because we want some live support isn't it?

A SD should always be fluidized to avoid clogging, so size does not matter. If not I would advise the 4" because I want the fresh water to be oxygen free as soon as possible. Rather smaller and higher than the opposite, flow from bottom to top.

Do you have each stage (sand filter, SD reactor, PO4 reactor, ARM) set up to recirculate?

Yes

Have you measured the difference of the effluent's ph?

Yes, I have constant monitoring. The en-fluent is degassed and aerated after the calcium-reactor to obtain normal till slightly higher system PH.

The amount of sulfur you recommend is substantially greater than what is usually suggested.

Is this to allow for greater ease in getting it dialed in, or for quicker results?

The ease of manipulating the output and avoiding the risk of uncompleted DE-nitrification.

Seems as if most recommendations are to remove a portion of the sulfur media once the nitrates are under control, but you recommend not removing the media , but increasing the reactor's infeed? I'm guessing when the nitrates reach zero, you need to increase the reactor's infeed substantially? And, once the tank's nitrates reach zero, do you keep increasing the reactor's infeed until you start getting NO3 readings from the effluent, then reduce the flow a little?

Why do we need the sulfur? If there is 0 nitrate the 2 types of anaerobe bacteria we need will feed on the sulfur and produce a small amount of sulfate which will meanly be bounded by the calcium media. A normal system will never be without nitrate.

Your guesswork proves you understand the process. The higher the turn over rate the more stable your system will be.When the flow rate gets to high, nitrite can be produced due to uncompleted DE-nitrification. This risk is a lot higher with a small amount of sulfur. I have had a flow rate of 10 x the amount of sulfur without problems but brought it down to provoke more calcification.

Why removing sulfur from an established system?