ghengis

New member

After some kind encouragement on another thread, I've decided to compile the process of building my dream tank. The pics I have are not strictly sequential or consecutive, as I never really planned to do a build thread, but there should be enough info to get the message across. If there are any questions, please fire away...

First up, as you can see from my profile, I've been a member here for a number of years, though mostly as a lurker. My background was the typical plastic 20L goldfish tank, that eventually became 45L, then 60 planted and scaped with lights and gas (CO2), and finally 225L fully scaped high tech... I started looking into salt water sometime during those years, before becoming a member here in '09. My dream for a reef tank came and went, grew momentum and faded as I decided to wait "just a little bit longer" numerous times over the past 10 or so years. Roll on 2020, my partner and I decided to design and build our first home, and it wasn't long before I had to pop the question..."Honey, can we build a marine aquarium into one of the walls in the house??" She was pretty sceptical, but I promised her a very modest budget lolspin::lolspin::lolspin::lolspin

lolspin::lolspin::lolspin::lolspin and she gave her consent.

and she gave her consent.

Our house design incorprated a 4 car garage (2x2 configuration), with the back section intended as my "man cave". The back wall here looked like the perfect spot for a makeshift fish room, with the tank itself mounted in the corner and visible within the lounge space and at the end of a small corridor that leads to the master bedroom.

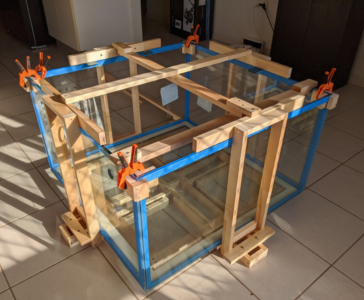

OK, enough background. As you're all well aware, the original design concept very quickly blew out, and I reckon I've spent nearly four times the original budget...but, I waited this long, and if I know one thing in life, it's to do something once and do it right. The build started in mid 2020 when I built the tank itself, and I got it wet in the first week of 2022....

Onto the show.

*NOTE - ALL MEASUREMENTS WILL BE IN METRIC :spin2:*

First up, as you can see from my profile, I've been a member here for a number of years, though mostly as a lurker. My background was the typical plastic 20L goldfish tank, that eventually became 45L, then 60 planted and scaped with lights and gas (CO2), and finally 225L fully scaped high tech... I started looking into salt water sometime during those years, before becoming a member here in '09. My dream for a reef tank came and went, grew momentum and faded as I decided to wait "just a little bit longer" numerous times over the past 10 or so years. Roll on 2020, my partner and I decided to design and build our first home, and it wasn't long before I had to pop the question..."Honey, can we build a marine aquarium into one of the walls in the house??" She was pretty sceptical, but I promised her a very modest budget

Our house design incorprated a 4 car garage (2x2 configuration), with the back section intended as my "man cave". The back wall here looked like the perfect spot for a makeshift fish room, with the tank itself mounted in the corner and visible within the lounge space and at the end of a small corridor that leads to the master bedroom.

OK, enough background. As you're all well aware, the original design concept very quickly blew out, and I reckon I've spent nearly four times the original budget...but, I waited this long, and if I know one thing in life, it's to do something once and do it right. The build started in mid 2020 when I built the tank itself, and I got it wet in the first week of 2022....

Onto the show.

*NOTE - ALL MEASUREMENTS WILL BE IN METRIC :spin2:*