You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Join me for a strange one...

- Thread starter kcress

- Start date

BeanAnimal

Premium Member

Yup... do not disagree, it is often the tools that we are least afraid (respectful) of that can do the most damage. The drill press is another tool that hurts a lot of folks because they don't realize how much damage it can do when a piece of work binds in the tool. Shattered bones (fingers, cheekbones, etc.) lacerations, and amoutations.

Power tool safety is not something to be taken lightly.

Power tool safety is not something to be taken lightly.

BeanAnimal

Premium Member

Having worked production furniture making before, I can tell you that, even with guards and safety measures in place, the bandsaw and planer account for most of the serious injuries. I myself was hospitalized for 4 days from a planer breaking a blade and kicking a board back at an angle and into my abdomen. We had at least 10 guys who "used to run a band saw" that were missing parts of a digit.

I have been working wood for 25+ years and never been hurt with a table saw, router, RAS or jointer. I had a near miss with a laser guarded bandsaw once and count myself lucky.

It does not take much to not pay attention and run your fingers through the bandsaw.

People don't tend to get hurt edge jointing, unless the board is too small to be jointed. Facing boards on the jointer is a different story and it scares me to this day. I am actaully looking for a thickness planer so that I don't have to worry about it!

Everyones Hero

New member

Just like women..it is the seemingly quiet ones you must watch out for!:lolspin:

I can't say much about the dangers of power tools, other than it would be cool to count to four & a half on your fingers, but I can attest to the quiet ones being trouble.

Just don't tell the girlfriend, she'd get mad as hell.

kcress

New member

Trying to make some headway here. I've been using kids to do the work in this tank. They're failing me. "I can't right now", "I don't feel like it. Can we do it later?", etc etc. Furthermore they don't have the hand-eye skills needed, nor the patience that will be required since I will need to polish out some scratches that are inside.

Long story short - I need to get into this tank. I don't fit thru 12" wide holes. I might fit thru a 14" wide hole. The tank openings at the top are really small looking to me. They're only 4 square feet total of a 12 square foot top.

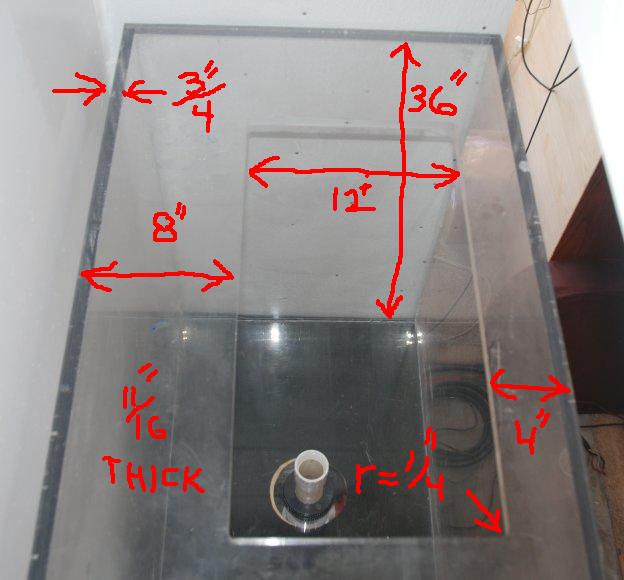

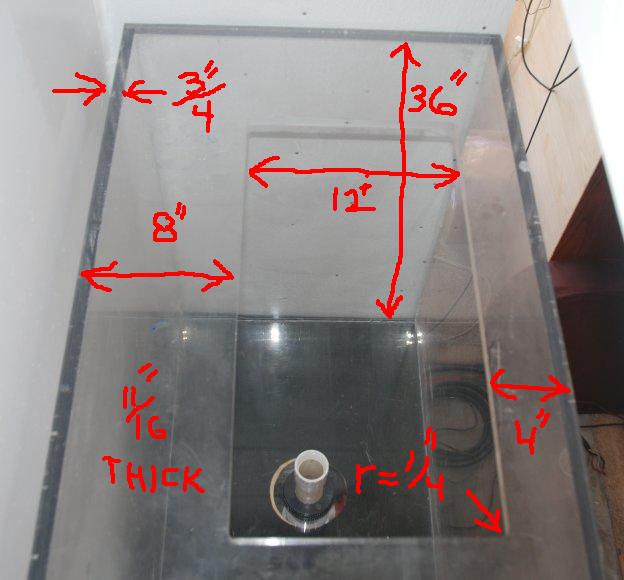

Here's the dimensions.

The question is, can I cut a few inches out of one of these openings, making the opening 15" by 24" instead of 12" by 24"? That would still leave six inches at the back while four seems to be enough at the front (stock).

That would still leave six inches at the back while four seems to be enough at the front (stock).

Long story short - I need to get into this tank. I don't fit thru 12" wide holes. I might fit thru a 14" wide hole. The tank openings at the top are really small looking to me. They're only 4 square feet total of a 12 square foot top.

Here's the dimensions.

The question is, can I cut a few inches out of one of these openings, making the opening 15" by 24" instead of 12" by 24"?

just make sure the corners are rounded.You can just use a 1/2" drill bit in the corners then cut into them. I can't see any reason that you couldn't make it 4" on both. If 4" holds the front then that is the weakes point anyway.

BeanAnimal

Premium Member

Rounded corners move stress away from the corner... square corners concentrate the stress right at the corner. A square corner will crack.

kcress

New member

; Thanks richierich2000, palmer373, and Bean for the responses.

Yeah I'm pretty amazed these corners only have a measly 1/4" radius. I'd expect something like 3/4 or 1".

So what do you guys think I should drill this with?

I do all my acrylic work on a CNC so I don't have any experience doing free hand acrylic mutilation..

If I want bigger radii can I use a hole saw?

Connecting the holes can I use a jig saw? What kind of blade on a jig saw? Fine tooth? Coarse? Hollow ground?

High blade speed or low?

Do I need to add water? (What a mess..)

I do have a hand router too.

Yeah I'm pretty amazed these corners only have a measly 1/4" radius. I'd expect something like 3/4 or 1".

So what do you guys think I should drill this with?

I do all my acrylic work on a CNC so I don't have any experience doing free hand acrylic mutilation..

If I want bigger radii can I use a hole saw?

Connecting the holes can I use a jig saw? What kind of blade on a jig saw? Fine tooth? Coarse? Hollow ground?

High blade speed or low?

Do I need to add water? (What a mess..)

I do have a hand router too.

khaosinc

The cyborg reefer

I've used hole saws to create a radius a couple times and worked quite well. I use water with those. For most the rest of my cutting I tend to use a jig saw as its quick and easy for me to find. I usually use metal bits and go slow, but this is more because thats what I tend to have around than anything. I don't use water with the jig saw, but if things get warm it will tend to melt the plastic rather than cut.

I wouldnt cut this with anything other than a router. With such an amazing build, I would take the time to build a jig (guide/fence) for the router that will yield a nice smooth edge. If you build a complete jig you can go completely around the opening (just shaving the front side) and increase the radius on all 4 corners, not just the new ones. I would also suggest another pass with small bevel to "ease" the resulting edge so you dont cut yourself getting in and out as well as working in the tank in the future.

eznet2u

Active member

hebygb; Can you please show me what router bit you'd use for this 11/16" acrylic.

Try this RS422, bottom right on first page. Just my opinion.

UpCut Router Bits.

:bigeyes:

kcress

New member

You velly funny boy....

Suckered me totally. :beer:

As for the bit. If I use that how do I guide the router?

oscarsdad608

New member

That is hilarious!

swearint

New member

As for the bit. If I use that how do I guide the router?

Most routers will accept a screw-in collar that is just slightly larger in outer diameter than the bit. The bit fits through the insert. You then build a template slightly larger than the area you want to cut out. The collar follows the edge of the template. Also, don't try to cut the full depth in one pass, make several passes a little at a time.

Todd

yes... the collar is a bearing that rolls against the guide/jig. I would suggest making this guide out of MDF. IFor example, if your desired tank opening size is 24 x 48, the MDF guide would be 25 x 49 (assuming that your bit is 1/2"). Like Swearin said, do not try and cut too much material away at a time... several passes are better than one cut.

I would use MDF because it will yield a smoother roll of the bearing.

If you want to be really sure of stability. build the MDF guide like a cap with sides that hang over the edge of the tank fitting like a lid. That way it will not move at all while you are working with the router. Measure twice, cut once.

I would use MDF because it will yield a smoother roll of the bearing.

If you want to be really sure of stability. build the MDF guide like a cap with sides that hang over the edge of the tank fitting like a lid. That way it will not move at all while you are working with the router. Measure twice, cut once.

Similar threads

- Replies

- 0

- Views

- 141

- Replies

- 3

- Views

- 138