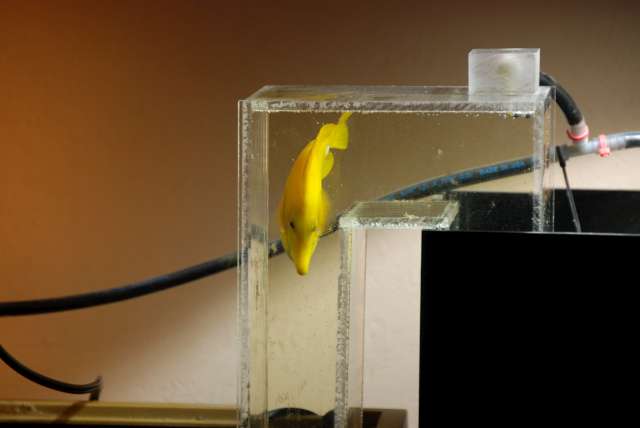

Wetness!

I brought the serpent in. Dealing with our hose which has 1-1/2" pipe from the meter to this hose bib and 100PSI backing it up is a lot like wrestling with a Boa. Of course the result is a lot of water fast and RO units that put out more than listed rates! :celeb1:

Starting the fill.

Proceeding with lots of nervous worry.

Almost full. There is something about admitting hundreds of gallons into one's living room thru a hard hose that is a bit unnerving.

Fullness of being.

A lot of checking going on. I also made sure the overflow bay filled. It is slowly draining into the tub below because the one un-valved stand pipe is only plugged into the bulkhead. I am quite surprised by how slowly it is leaking out. It's about 2" into that sump bin in 8 hrs. It will stop once the overflow space empties.

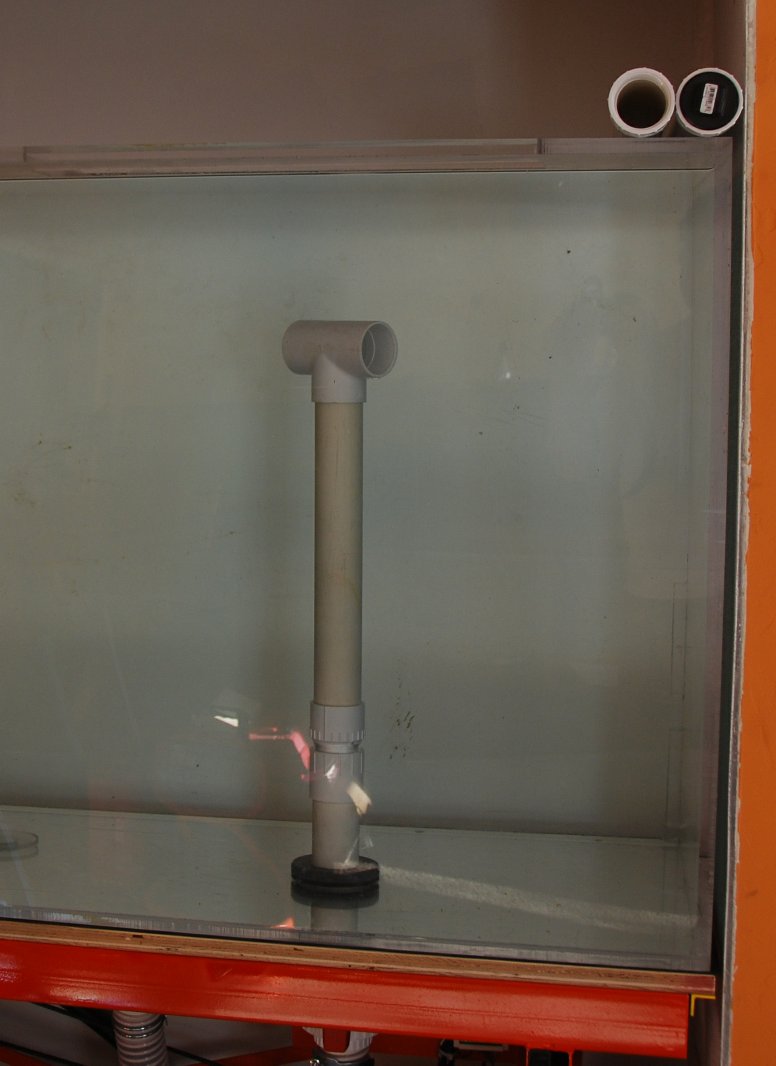

Now for some flow fun.

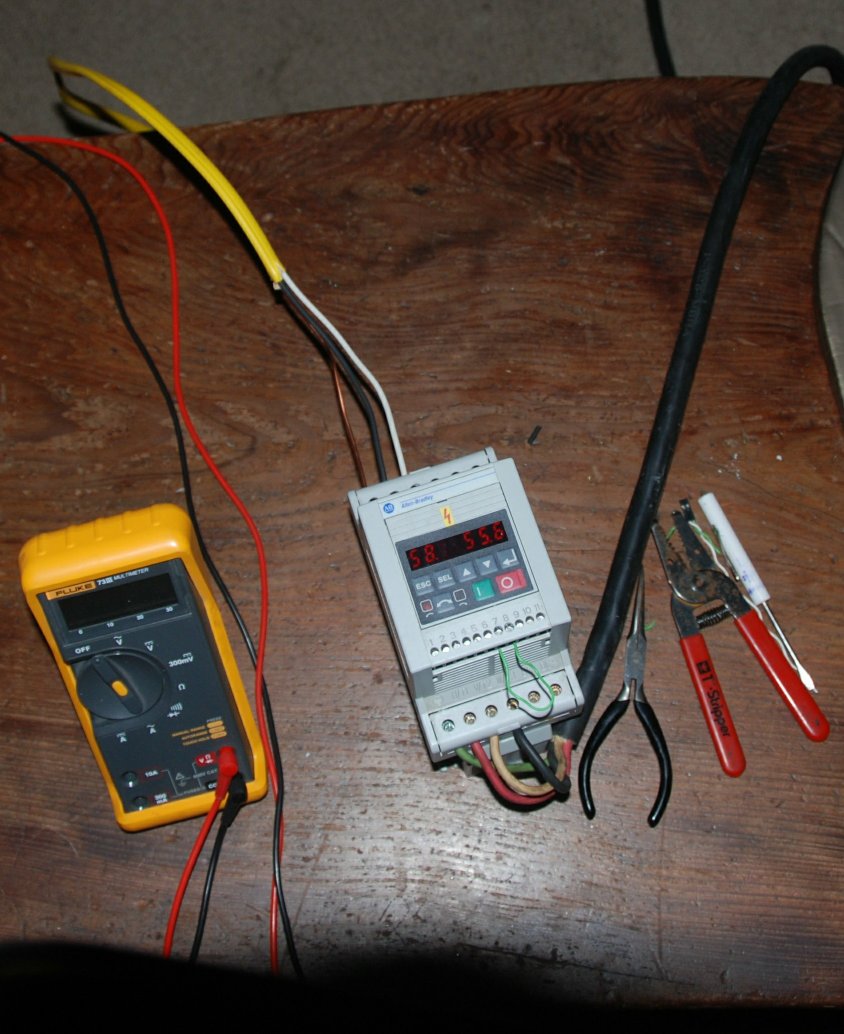

Using the VFD Adam so generously donated and the 240Vac line that was feeding my previously retired VFD I fired up the pump, but not before carefully and slowly starting the motor to confirm rotation direction.

If you run these pumps at full speed in reverse the impeller will back off the shaft. Worse, as it backs off it collides with the volute chamber. This stops it and causes it to fully unscrew instantly, thus acting like a screw press. Generally the pump housing will explode or split open. That would be a

Bad Thing.. :thumbdown

Here you can see I have it running at about 92%.

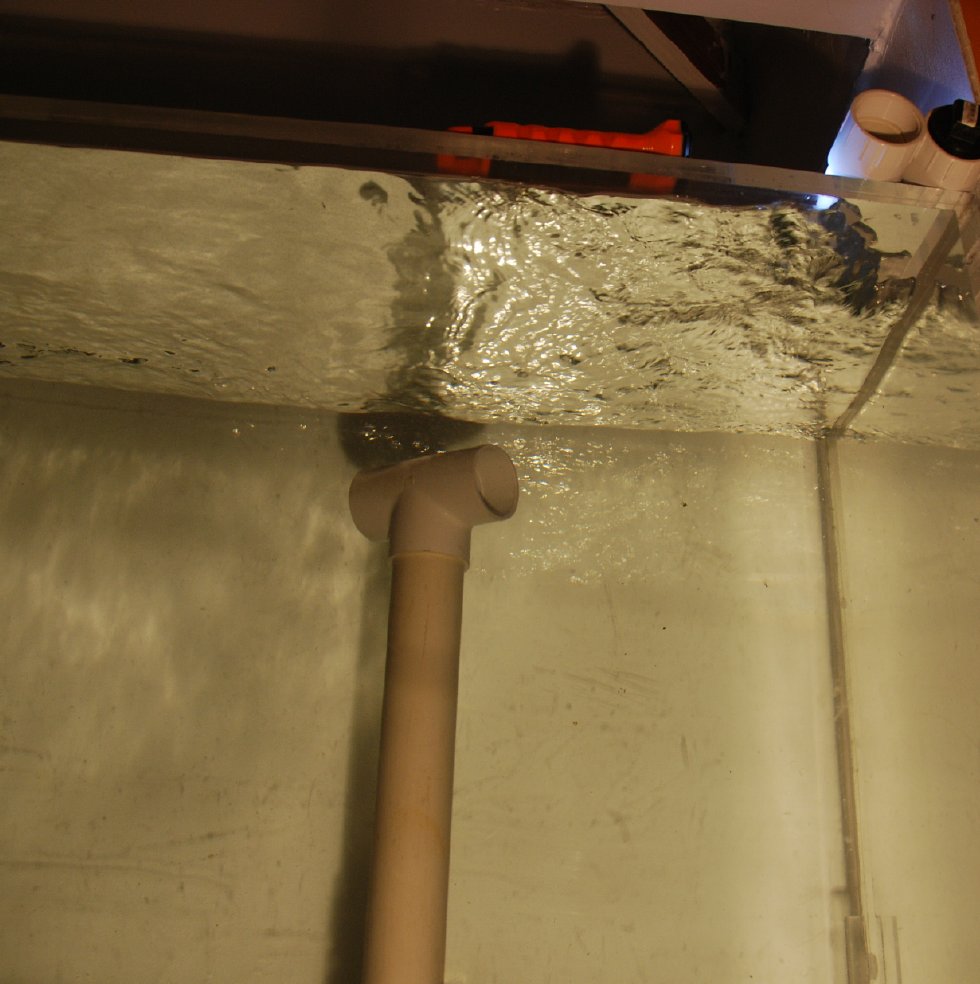

Because I have no outlet restriction and upped the impeller size I'm getting cavitation. This is because the pump can expel water faster than it can draw in water and the water starts to boil at the impeller face. Once I put some restriction in in the form of eductors, that won't be a problem, because the head pressure will go up reducing the flow thru the pump. I'll still be delivering 1/2 hp into the water column though, and the eductors will also amplify that flow.

You can see here that the water being shot out the right outlet is causing the surface to rise to the top of the tank.

Here's a shot from below. You can't see it in a still photo but that outlet pipe is shaking like a constipated dog.

After running the pump for an hour the motor was about 90F. I'm happy about that as it's not going to heat the air a bunch.

I will say that VFD really made the motor sing.. in X sharp. The dog bailed post haste and the daughter asked, "is that how it's always going to sound?!" The 8kHz modulation freq is just too low.

So now I wait to see what transpires.