You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Just a little grow out system build.. open to advice and suggestions

- Thread starter bvysochin

- Start date

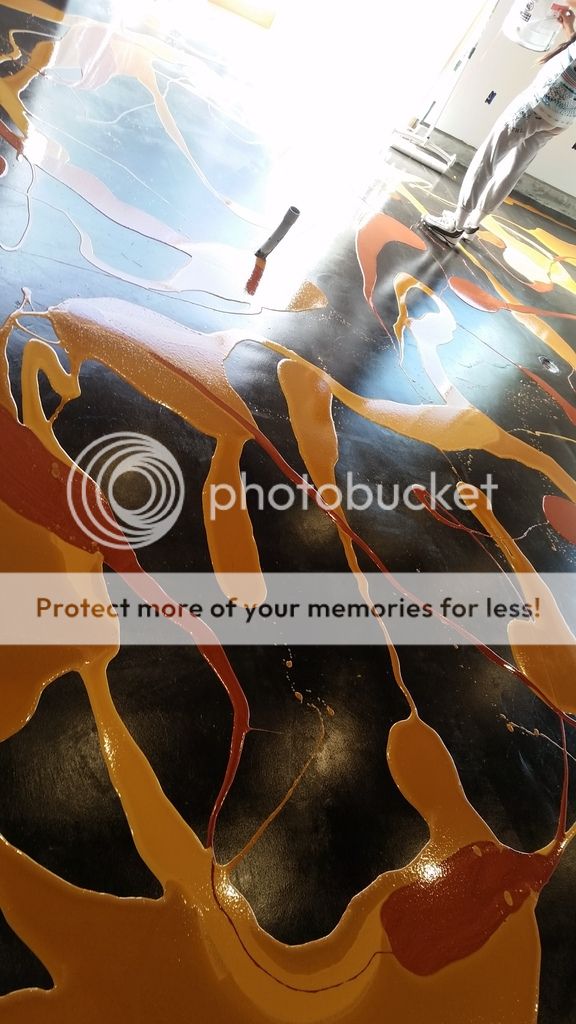

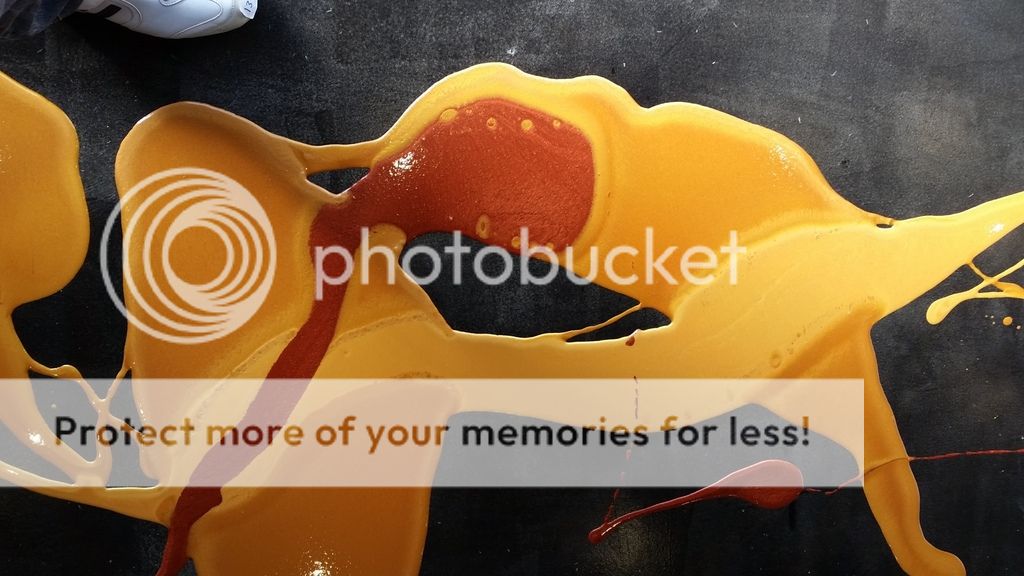

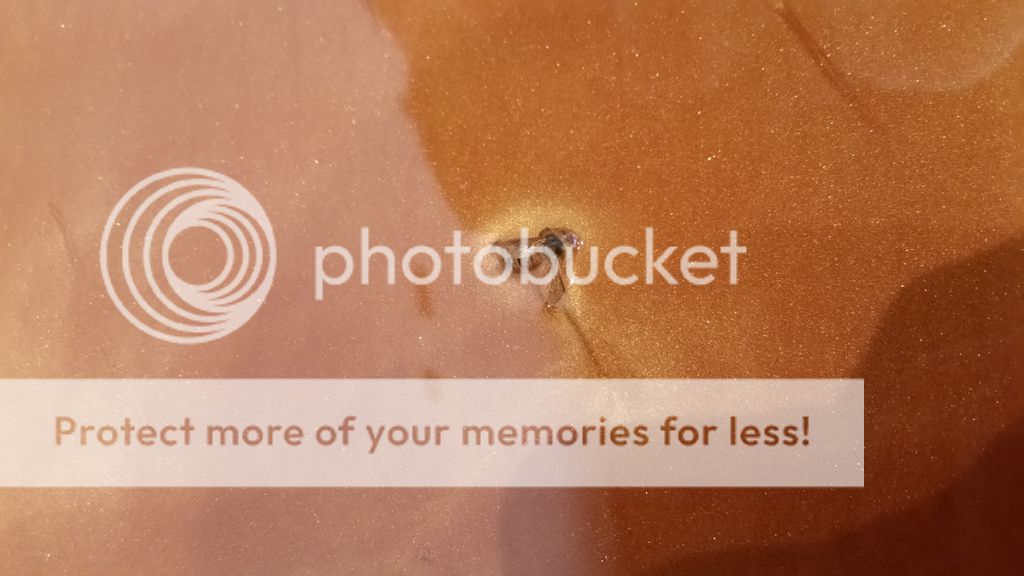

How the colors all go together...

Little trimming..

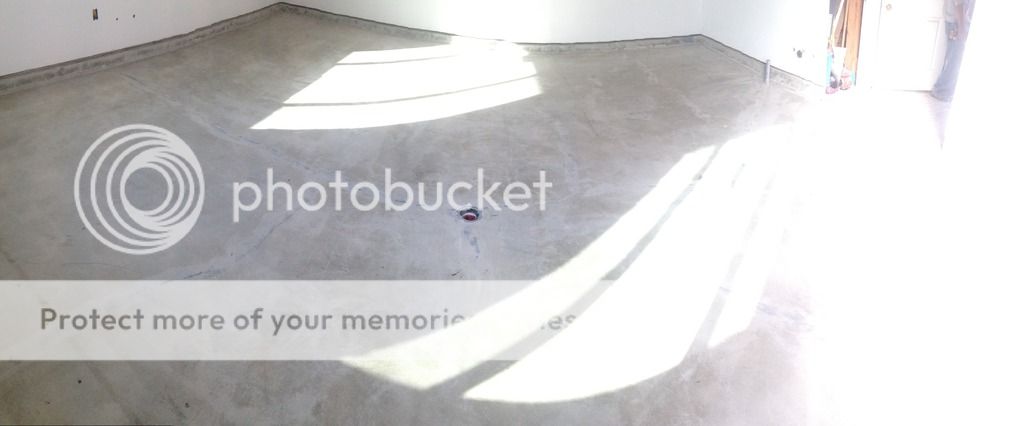

Epoxy'ing the concrete curb.. Angle stops are on..

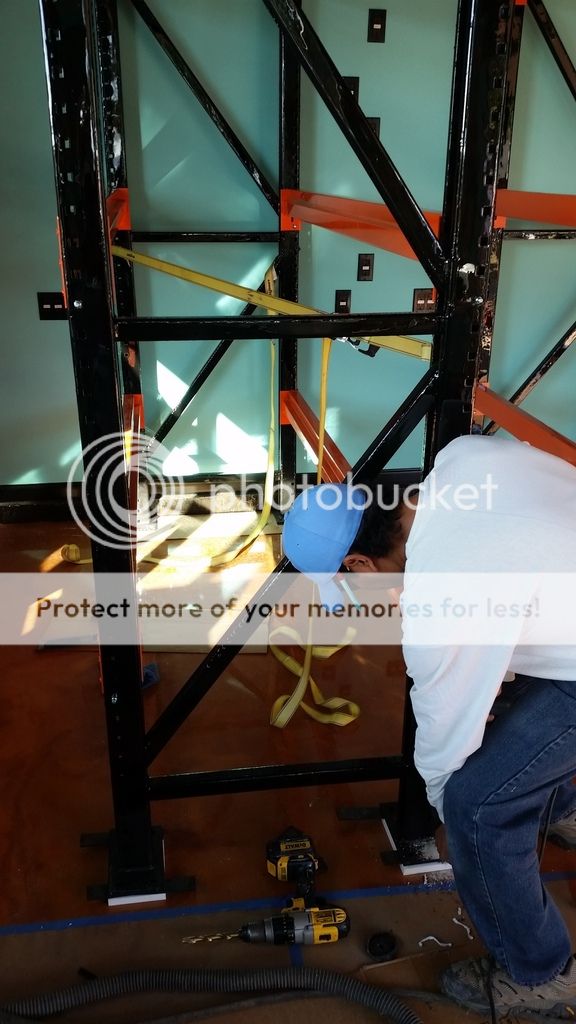

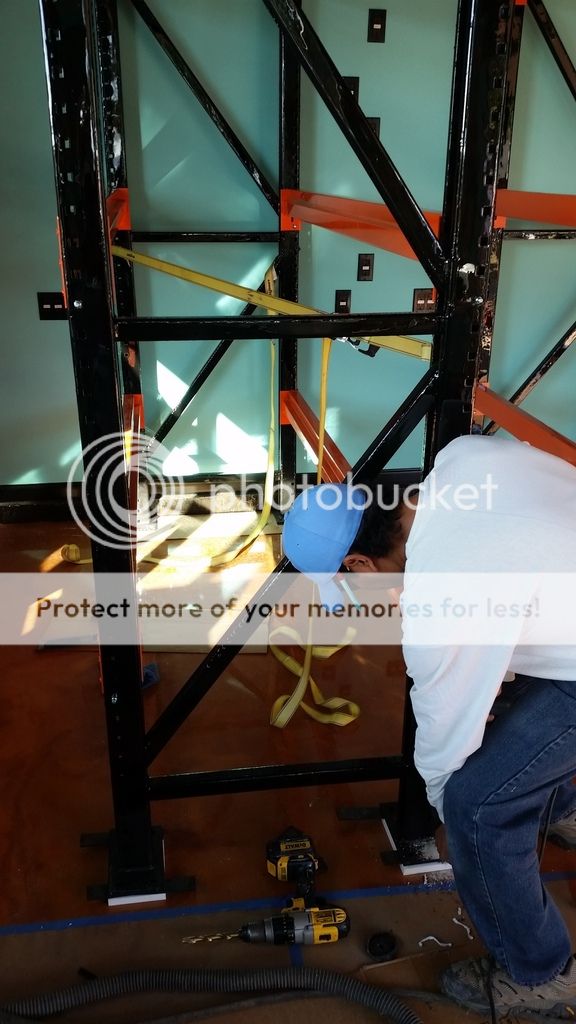

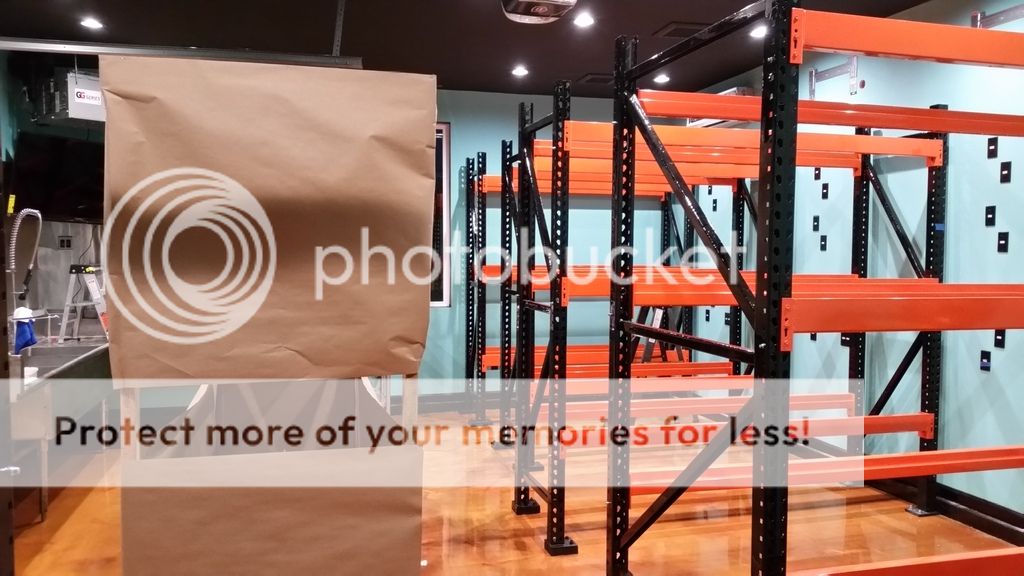

Wanted the racks to stay durable.. but didn't want to spend 3x the cost of the racks to re-powdercoat them.. so we decided to epoxy them, as we had a lot left over. Came out okay. Learned that vertical surfaces are difficult... and runs are inevitable. Oh well.. it looks good enough for what we will be using them for.

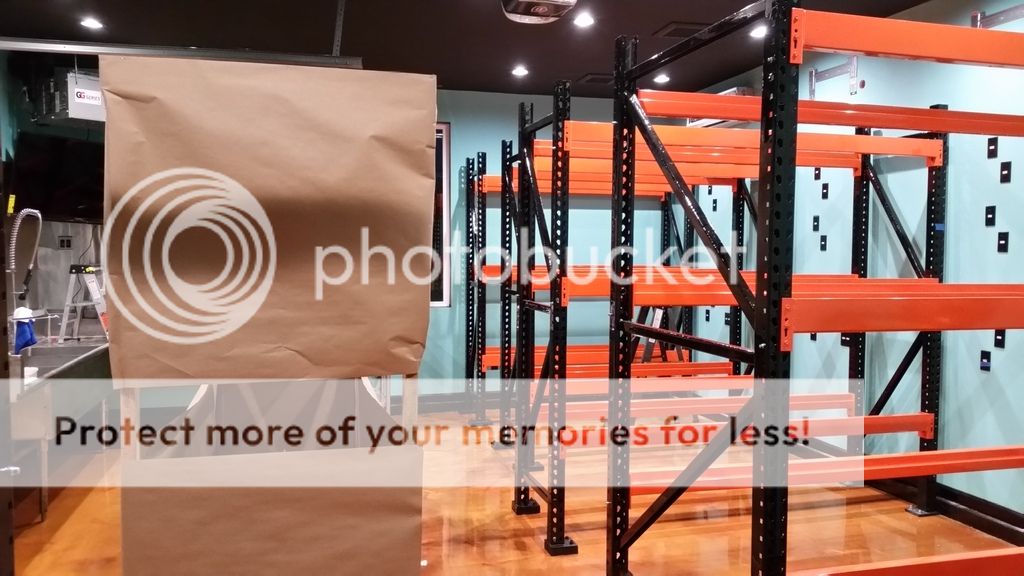

Mock up of the racks.. Had to take them back out to fit the sink in..

Back splash going in.. Sink being welded back together and going in!

Always wanted to learn how to weld and had a few more spots on the stainless sink that we wanted to touch up.. plus have some future aluminum fab in mind to complete this project.. so we had an excuse to get another new toy. Wanted red or blue, but couldn't justify the price for a nice tig. This'll have to do for now!

Sink is in.. still waiting trim/silicone. Learned the importance of getting a quality backsplash mounting kit and the importance of tapered brass fittings!! :wacko (2):

TV going in.. everybody's gotta have a TV by the fragging station!

Meanwhile.. our current systems have been declining.. the lack of maintenance is really starting to show.. We're optimistic that everything will bounce back. This was a few months worth of caulerpa in the sump..

No going back now.. racks being bolted down.

Couldn't figure out why the gaps weren't lining up.. didn't realize how far out of square these things were. Horrible..

If anybody ever decides to use them for a similar future project, make sure you square them up!!

Always wanted to learn how to weld and had a few more spots on the stainless sink that we wanted to touch up.. plus have some future aluminum fab in mind to complete this project.. so we had an excuse to get another new toy. Wanted red or blue, but couldn't justify the price for a nice tig. This'll have to do for now!

Sink is in.. still waiting trim/silicone. Learned the importance of getting a quality backsplash mounting kit and the importance of tapered brass fittings!! :wacko (2):

TV going in.. everybody's gotta have a TV by the fragging station!

Meanwhile.. our current systems have been declining.. the lack of maintenance is really starting to show.. We're optimistic that everything will bounce back. This was a few months worth of caulerpa in the sump..

No going back now.. racks being bolted down.

Couldn't figure out why the gaps weren't lining up.. didn't realize how far out of square these things were. Horrible..

If anybody ever decides to use them for a similar future project, make sure you square them up!!

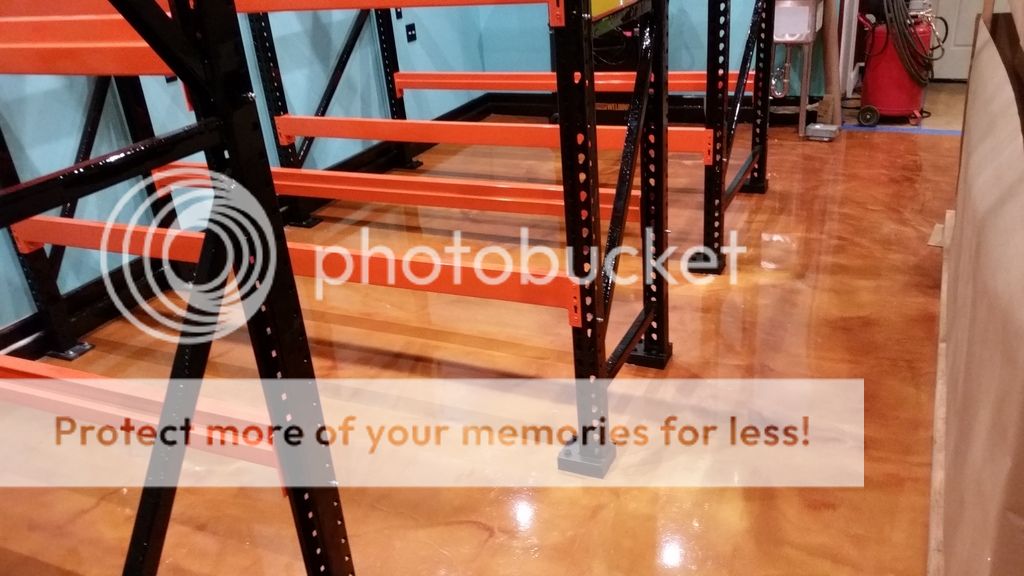

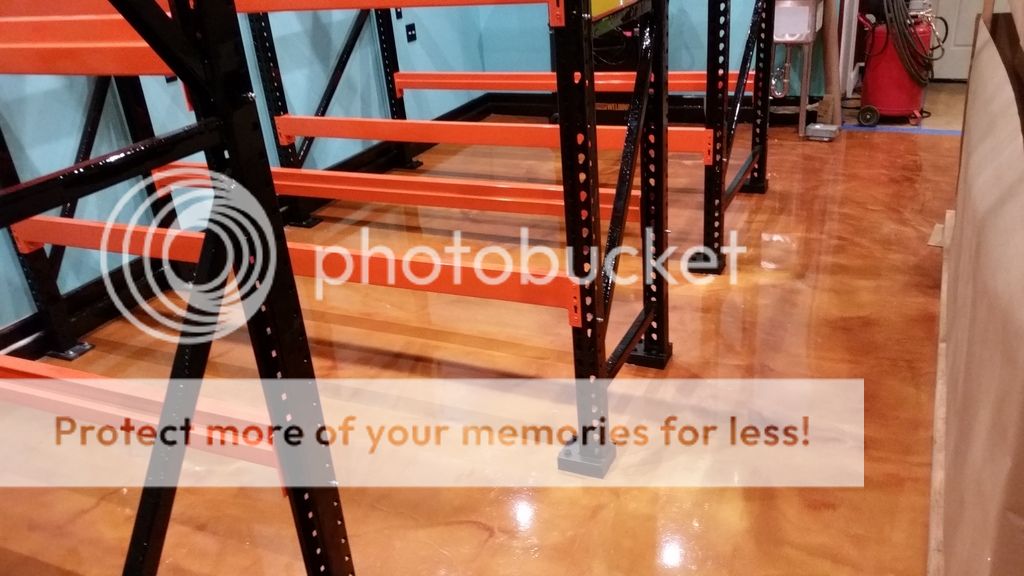

Racks bolted down.. The slope on the floor was definitely present.. Had to shim the ends of the racks over 2" to get them level and for the tank overflows to work correctly. Used composite shims and PVC to elevate the feet.. Wanted something somewhat moisture resistant.

Feet were all sprayed 1' up with rubber coating 3X. Then siliconed to the floor, as we didn't want any water to accumulate underneath.

One rack will have to come back out to allow us to somehow lift/raise the 535 lb frag tank 8' up in the air onto the shelf..

The cardboard looking box in the middle room is a mock-up of where the future 10' display tank will be positioned. Bummer that we lose so much of the room space, but it'll be a cool display tank, and hopefully worth it!

QT corner..

More rack shots..

Garage door opener installed. Excuse the wires.. still need to clean up/do final touch up.

As a side note.. Opener works great, now that I figured out that one wire was simply unplugged during transport (I'm guessing). No thanks to Craftsman, who has the crappiest customer service I have ever dealt with. Oh wait.. no customer service at all.. their reps from India refused to help me over the phone and stated that although the opener was still under warranty for the next three years, I had to have a technician come out to diagnose why it wasn't working. At my expense. No thanks, I'll figure it out on my own. Never again!

Another sink shot.. excuse the mess. Still waiting for the trim/moldings to arrive.

Just started installing the mini-split units.. We've decided to tackle this on our own and have started accumulating tools to complete our installation.

Got a nitrogen tank, and regulator so far. About to order a digital manifold set/micron gauge, 25lb tank of R410a, nylon thread sealant, and a flaring tool. Any HVAC techs want to offer some advice on anything else we may need?

That's it for now.. will be renting a box truck to pick up the glass tanks this week. :bounce2:

Feet were all sprayed 1' up with rubber coating 3X. Then siliconed to the floor, as we didn't want any water to accumulate underneath.

One rack will have to come back out to allow us to somehow lift/raise the 535 lb frag tank 8' up in the air onto the shelf..

The cardboard looking box in the middle room is a mock-up of where the future 10' display tank will be positioned. Bummer that we lose so much of the room space, but it'll be a cool display tank, and hopefully worth it!

QT corner..

More rack shots..

Garage door opener installed. Excuse the wires.. still need to clean up/do final touch up.

As a side note.. Opener works great, now that I figured out that one wire was simply unplugged during transport (I'm guessing). No thanks to Craftsman, who has the crappiest customer service I have ever dealt with. Oh wait.. no customer service at all.. their reps from India refused to help me over the phone and stated that although the opener was still under warranty for the next three years, I had to have a technician come out to diagnose why it wasn't working. At my expense. No thanks, I'll figure it out on my own. Never again!

Another sink shot.. excuse the mess. Still waiting for the trim/moldings to arrive.

Just started installing the mini-split units.. We've decided to tackle this on our own and have started accumulating tools to complete our installation.

Got a nitrogen tank, and regulator so far. About to order a digital manifold set/micron gauge, 25lb tank of R410a, nylon thread sealant, and a flaring tool. Any HVAC techs want to offer some advice on anything else we may need?

That's it for now.. will be renting a box truck to pick up the glass tanks this week. :bounce2:

deaclauderdale

Lover of Fishies

Now that's what I'd call an update!

Reef keeping is life!

Reef keeping is life!

Notquiterite

New member

Wow Crystal! You weren't kidding when you were saying it was under construction! I can't believe the amount of work that has been done since the last time I've been over there. Tagging along to see where this ends up

Joe Kelley

Active member

Incredibly awesome!! Nice work!

savethereef

SCRK

Excellent work on this!

I can see a lot of blood and Sweat was put in this.

I cant wait to see this in person.

Keep up the great work.

I can see a lot of blood and Sweat was put in this.

I cant wait to see this in person.

Keep up the great work.

wishntoboutside

professional snow flake

Very impressive to say the least and you don't have any tanks in it yet.

Beyond crazy build.

Beyond crazy build.

This is just Insane

I'm trying to build a frag system and this just makes feel defeated lol

Ha! Don't feel defeated.. Feel motivated! After seeing a few build threads here, that's what motivated us to do this project.

Wow Crystal! You weren't kidding when you were saying it was under construction! I can't believe the amount of work that has been done since the last time I've been over there. Tagging along to see where this ends up

Yep! We've been real busy, working on it whatever days we have free. You'll have to come by in person once everything is more situated!

Now that's what I'd call an update!

Reef keeping is life!

Thanks.. update has been long overdue

Incredibly awesome!! Nice work!

Thanks!

that is sick...i cant even find motivation to build a stand for a 20 gallon.

Thanks! It's all definitely time consuming, that's for sure!

Those floors are amazing! Soon as I hit the powerball jackpot expect to see a build thread very similar

Thanks! We saved up for a while to make this happen, and have been fortunate to be able to do the majority of the work ourselves.. Couldn't imagine what a general contractor would charge..

What the what?!?! Awesomeness!

Haha, Thanks!

Excellent work on this!

I can see a lot of blood and Sweat was put in this.

I cant wait to see this in person.

Keep up the great work.

Thanks Rob! Lots of planning, that's for sure!

Very impressive to say the least and you don't have any tanks in it yet.

Beyond crazy build.

Thanks! Hopefully once the tanks are in place this week/next week, we can start to transfer stuff over and get this new system running, at least with some sort of temporary sump. We're still aiming to get at least one tank wet by the end of the year.

Build a Build for a Build....I bow down to you sir!

Thanks!

Invertebrated

New member

Well I'm actually a concrete finisher having done floors for many years and feel like you guys did a great job on that floor it looks really nice ! So , you picked a good spot too save money and do it yourself (even though you initially wanted a contractor) great job. (fighting back jealousy)

Sent from my LGMS550 using Tapatalk

Sent from my LGMS550 using Tapatalk

Similar threads

- Replies

- 14

- Views

- 195

- Replies

- 2

- Views

- 30

- Replies

- 11

- Views

- 214